Water flow control is simple… until it isn’t. Picture this: You’ve installed a pump in a wastewater system. But when the pump shuts off, chaos erupts. Liquids flow backward, pressure surges threaten pipes, and equipment risks damage. What’s missing? A check valve.

Check valves are the unsung heroes of fluid control systems. They quietly ensure fluids move in one direction—preventing spills, leaks, and catastrophic failures.

But what does a check valve do exactly? And why is it non-negotiable for plumbing, industrial setups, and even your home’s irrigation system?

Let’s break it down.

Table of contents

What Is a Check Valve?

A check valve (or non-return valve) is a one-way gatekeeper for fluids. Its sole job? Let flow move forward while blocking reverse flow. No electricity. No manual control. Just smart engineering.

Think of it like a traffic cop for water, air, or chemicals. If the flow tries to U-turn, the valve slams shut—saving pumps, pipes, and entire systems from damage.

How Check Valves Work: The 15-Second Explanation

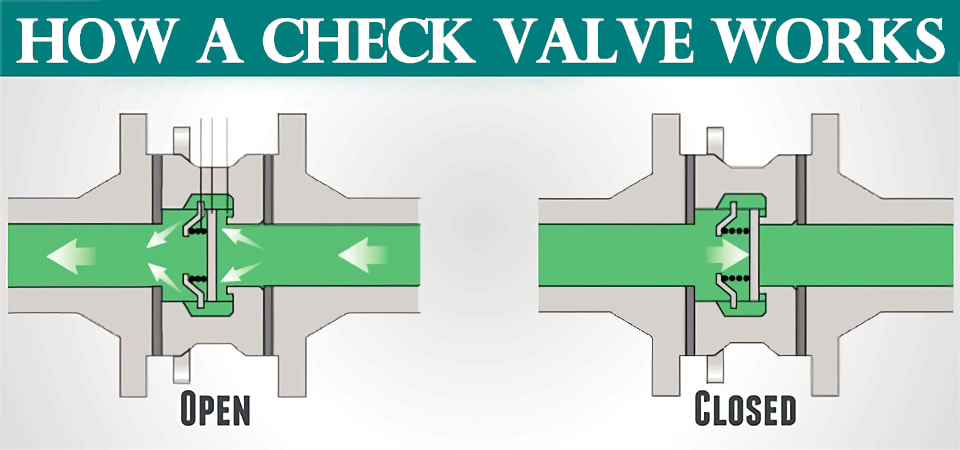

Check valves use dynamic flow pressure to operate. Here’s their 3-step process:

1. Forward flow opens the valve. Fluid pressure pushes the valve’s disc, ball, or diaphragm open.

2. Flow stops? The valve closes automatically. Gravity, springs, or backpressure snap it shut.

3. Reverse flow? Not happening. The closed valve seals tight, blocking backflow.

It’s a fail-safe design—no human intervention needed.

6 Critical Functions of Check Valves

1. Prevent Costly Backflow

Backflow is public enemy #1 for pipelines. Contaminated water flowing backward into clean supplies? Toxic chemicals mixing? Check valves stop these disasters by sealing the moment reverse flow starts.

2. Protect Pumps & Equipment

Pumps and compressors self-destruct if fluids reverse. Check valves act as **mechanical bodyguards**, preventing:

– Impeller damage from reverse spin

– Pipe collapse due to vacuum pressure

– Motor burnout

3. Reduce Water Hammer

Ever hear a loud bang in your pipes? That’s water hammer—a pressure surge that cracks pipes. Check valves dampen this shock by closing before pressure spikes.

4. Minimize Downtime & Maintenance

Check valves isolate sections of systems. Need to repair a pump? Close the valve, work safely, and avoid shutting down the entire operation.

5. Maintain Pressure

Backflow drains pressure. Check valves keep systems pressurized for consistent performance in:

– HVAC systems

– Hydraulic machinery

– Fire suppression setups

6. Save Energy (and Money)

No backflow means pumps don’t waste energy fighting reverse flow. Efficiency jumps—and so do your savings.

7 Types of Check Valves (+ Best Uses)

| Type | How It Works | Ideal For |

|---|---|---|

| Swing Check Valve | Hinged disc swings open/closed | Water systems, low-pressure |

| Ball Check Valve | Ball lifts with flow, seals when reversed | Sewage, viscous fluids |

| Lift Check Valve | Piston lifts vertically for flow | High-pressure steam, oil/gas |

| Wafer Check Valve | Thin design fits between pipe flanges | Tight spaces, HVAC |

| Dual Plate Valve | Two spring-loaded plates snap shut | Preventing water hammer |

| Foot Valve | Screen-filtered valve at pump inlets | Keeping pumps primed |

| Silent Check Valve | Spring-assisted closure minimizes noise | Apartments, hospitals |

Pro Tip: Pair silent check valves with surge tanks for ultra-quiet plumbing.

How to Choose the Perfect Check Valve (2025 Guide)

Factor 1: Flow Rate & Pressure

– High flow? Use a swing or tilting disc valve.

– Low pressure? Avoid heavy spring-loaded designs.

Factor 2: Material Compatibility

– Chemicals: PTFE or stainless steel

– Water: Brass or PVC

– Oil/Gas: Carbon steel

Factor 3: Installation Orientation

– Swing valves need horizontal pipes.

– Lift valves work vertically.

Factor 4: Temperature Limits

– Plastic valves melt above 140°F.

– Metal handles up to 1,000°F.

Factor 5: Maintenance Needs

– Easy-clean valves: Ball or dual plate

– Low maintenance: Wafer or silent

Factor 6: Cost vs. Lifespan

– Cheap valves fail faster. Invest in cast steel or coated brass for decades of use.

Check Valves in Action: 3 Real-World Examples

1. Home Plumbing

– Problem: Toilet water siphoning into clean supply.

– Fix: Install a dual-check valve on the mainline.

2. Oil Refineries

– Problem: Reverse flow causes explosive pressure.

– Fix: Lift check valves isolate refinery sections.

3. Municipal Water Treatment

– Problem: Contaminated backflow risks public health.

– Fix: Wafer check valves between treatment stages.

Key Takeaway

So, what does a check valve do? It’s your system’s first defense against chaos—blocking backflow, saving equipment, and keeping operations smooth.