You’ve probably noticed some strange markings on ball valves before. Terms like “WOG,” “CWP,” and “WSP” are common. But what do they actually mean?

These abbreviations refer to different valve pressure ratings. And understanding them is crucial for selecting the right ball valve for your application.

In this post, as a professional ball valve manufacturer, I’ll explain exactly what WOG means on a ball valve. I’ll also cover other important ball valve markings so you can pick the perfect product.

What Does WOG Stand For?

WOG stands for “water, oil, gas”. It’s a non-shock pressure rating that specifies the maximum pressure per square inch (PSI) a ball valve can handle at ambient temperatures.

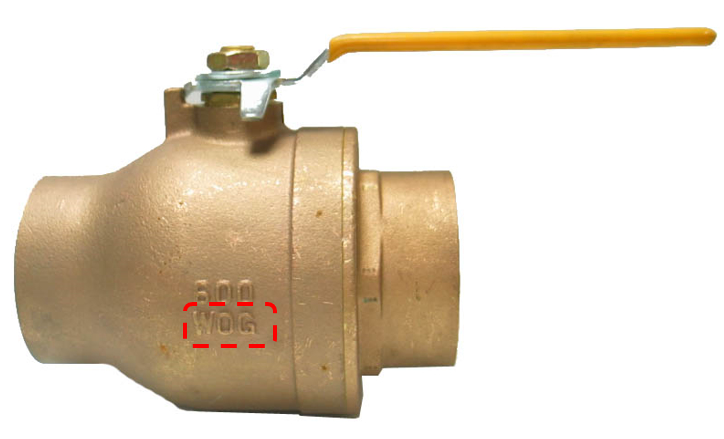

For example, a ball valve marked “600 WOG” can withstand up to 600 PSI.

So if your system operates at 500 PSI or less, a 600 WOG valve should do the trick. Exceed the WOG rating though and leaks (or even explosions) can occur.

WOG ratings generally range from 150 to 4,000 PSI for ball valves. Low-pressure residential applications use lower WOG valves. High-pressure industrial processes require extremely durable valves with maximum WOG ratings.

Why Was WOG Created?

The term WOG emerged years ago before advanced valve testing. Engineered products weren’t always reliable back then.

So valve manufacturers started marking products “WOG” to indicate they were suitable for water, oil, and gas applications. This gave users more confidence in valve performance.

Of course, the oil and gas designations came with limitations:

- Oil referred to free-flowing, lubricating liquids only. Using a WOG valve with thicker petroleum products may cause issues.

- Gas indicated non-flammable gases. WOG doesn’t mean a valve is suitable for combustible fuel gases.

These days, more specific testing procedures and ratings (like ANSI) provide better valve performance indicators. Even so, WOG remains as a legacy metric that still assists valve selection today.

How Does WOG Compare to Other Ratings?

While ubiquitous, WOG isn’t the only valve pressure rating out there. CWP, PSI, and other metrics also help dictate proper valve application:

PSI Pressure Rating

PSI (pounds per square inch) is the actual pressure measurement marked on many valves. For example, a valve may be rated for 600 PSI at ambient temperatures.

Any rating – whether WOG, CWP, or other – converts to an equivalent PSI value. So WOG and PSI pressure ratings correlate directly.

CWP Rating

CWP means “cold working pressure,” indicating a valve’s pressure handling capability from -20°F to 100°F.

WOG and CWP are nearly synonymous. Both refer to non-shock ambient temperature pressure limits. Generally, CWP is replacing WOG as the more common standard.

For temperatures exceeding 100°F, other ratings like WSP come into play.

WSP Rating

WSP stands for “working steam pressure,” specifying the highest pressure rating possible for steam service.

For example, a valve marked “150 WSP” can handle a 150 PSI steam system at saturation temperatures above 300°F.

So while interchangeable at ambient temperatures, WSP always denotes lower pressure capabilities than WOG or CWP.

Why Proper Pressure Rating Matters

Exceeding a ball valve’s pressure rating spells trouble. Issues like:

- Leaking seals

- Distorted valve bodies

- Failed actuators

- Hazardous operating conditions

That’s why confirming adequate WOG, PSI, and other ratings is so important. It keeps assets safe while preventing unplanned downtime.

Consider this scenario:

A plant operator installs a 150 WOG valve in a 200 PSI water line. The valve’s too weak for this relatively low-pressure application. It soon starts leaking, requiring an emergency plant shutdown for repair.

This lesson applies to steam systems too. For example, replacing a burst 300 WOG valve with 150 WSP alternative could have the same leaky outcome.

Checking valve pressure ratings takes just seconds before installation. But prevents costly headaches down the road.

Other Key Ball Valve Markings

While WOG and other pressure ratings are most critical, additional labels offer insight into ball valve construction and compliance:

Size – Valve pipe size in inches (or millimeters for DN metric designation).

Material – Body material code, like CF8M for 316 stainless steel.

Standards – Third-party certifications like ANSI, ensuring product testing and quality.

Manufacturer – Company name responsible for engineering and production.

So if leaky valves have you fed up, make WOG your friend. Understanding what that cryptic little abbreviation means keeps assets safe while avoiding downtime disasters.

In Conclusion

To summarize, WOG stands for “water, oil, gas” and indicates the maximum pressure per square inch (PSI) a ball valve can withstand at ambient temperatures. Checking a valve’s WOG, PSI, and other ratings ensures suitability for a given application, preventing leaks and potential catastrophes.