Ball Valves

Ball valves are used to control the flow of water, oil, steam, air, slurries, and corrosive fluids. They can be found in petrochemical processing, food processing, water distribution systems, automatic combustion systems, and instrumentation control.

While there are various parts within a ball valve (e.g., stem, stem nut, ball, body), one of the most crucial parts is the ball valve seat. Ball valve seats have two main jobs: distribute seating stress uniformly and achieve a solid seal — and to accomplish this they must be made from the right material.

What is PEEK Valve Seat Material?

PEEK is the common name for Poly Ether Ether Ketone. It is a high performance engineered thermoplastic. It offers excellent chemical and water resistance and is unaffected by continuous exposure to hot water or steam. Its temperature stability is good to 550°F and it is a high strength alternative to fluoropolymers used for valve seats. These properties make it a superb seat choice for elevated pressure coupled with elevated temperature. ZECO Valve offers PEEK valve seat in two grades, unfilled and filled. The filled is a unique blend of carbon/graphite fillers to ensure consistent, uniform material properties. This lowers the coefficient of friction, reducing the operating torque requirements of our valves.

What is the Advantage of PEEK Valves Seat

PEEK Seat ball valve have good seal performance and high temperature resistance with soft seat structure,As a kind of high-performance polymer material, PEEK is characterized by low creep variable, high elastic modulus, excellent wear resistance and corrosion resistance, chemical resistance, non-toxic, flame retardant, still maintain good performance even at high temperature/pressure and high humidity under the poor working conditions, PEEK Seat ball valve can be used for high temperature and high-pressure valves, nuclear valves, pump compressor valve plates, piston rings, valve and the core of the sealing parts. Why PEEK seat ball valve valve is so popular that depends on PEEK’s excellent characteristics.

| Material Name | Main Properties | Notes/Applications | Temperature Range |

| Virgin PEEK | Excellent chemical resistance and mechanical properties at elevated temperatures High tensile strength and dimensional stability | FDA approved Most effective as a seal, backup ring, V-packing or Chevron seal Used as rotary seals in Nuclear applications | -40°C to 260°C |

| Carbon filled PEEK | Many similar properties to Virgin PEEK. Particularly suitable for elevated temperatures and high load situations. | Low coefficient of friction and suitable for many extremely corrosive applications | -40°C to 260°C |

| Glass filled PEEK | Many similar properties to Virgin PEEK. Particularly suitable for elevated temperatures and high load situations. | Low coefficient of friction and suitable for high wear applications | -40°C to 300°C |

| PTFE filled PEEK | Many similar properties to Virgin PEEK. Particularly suitable for elevated temperatures and high load situations. | Higher lubricity than Virgin PEEK. Suited to sealing applications where start-stop or rotary motions are involved at higher RPMs | -40°C to 260°C |

High Temperature Resistant of PEEK seat ball valve

PEEK resin offers a high melting point (334℃) and glass transition temperature (143 ℃). Its continuous use temperature can be up to 260℃and load thermal transformation temperature of 30%GF or CF reinforced brand is up to 316℃.

Mechanical properties of PEEK Seat Ball Valve

PEEK raw material resin has good toughness and rigidity, and it has excellent fatigue resistance to alternating stress comparable to alloy materials.

Flame Retardant of PEEK

Flammability of materials, which is specified in standards UL94, is the ability to maintain combustion after being ignited with high energy from oxygen and nitrogen mixtures. First, a vertical sample of a certain shape is ignited, and then measured the time taken by the material to automatically extinguish. PEEK test results are v-0, which is the optimal level of flame retardancy.

Stability of PEEK

PEEK plastic materials have superior dimensional stability, which is important for some applications. The environmental conditions such as temperature and humidity have little impact on the size of PEEK parts which can meet the requirements of high dimensional accuracy.

- PEEK plastic raw material has a small shrinkage in injection molding, which is beneficial to control the dimensional tolerance range of PEEK injection parts, making the dimensional accuracy of PEEK parts much higher than that of general plastics;

- Small coefficient of thermal expansion. The size of PEEK parts changes little with the change of temperature (which may be caused by the change of ambient temperature or friction heating during operation).

- Good dimensional stability. The dimensional stability of plastics refers to the dimensional stability of engineering plastics in the process of usage or storage. This dimensional change is mainly due to the increase of activation energy of polymer molecules caused by some degree of a crimp in the chain segment.

- Outstanding thermal hydrolysis performance. PEEK is low in water absorption under high temperature and humidity. No obvious change in size caused by water absorption of common plastics like Nylon.

PEEK was developed in just two decades, has been widely used in oil and gas, aerospace, automotive manufacturing, electronics, medical and food processing and other fields. In the oil and gas industry, PEEK’s exceptional performance makes it ideal for use as a primary sealing part.

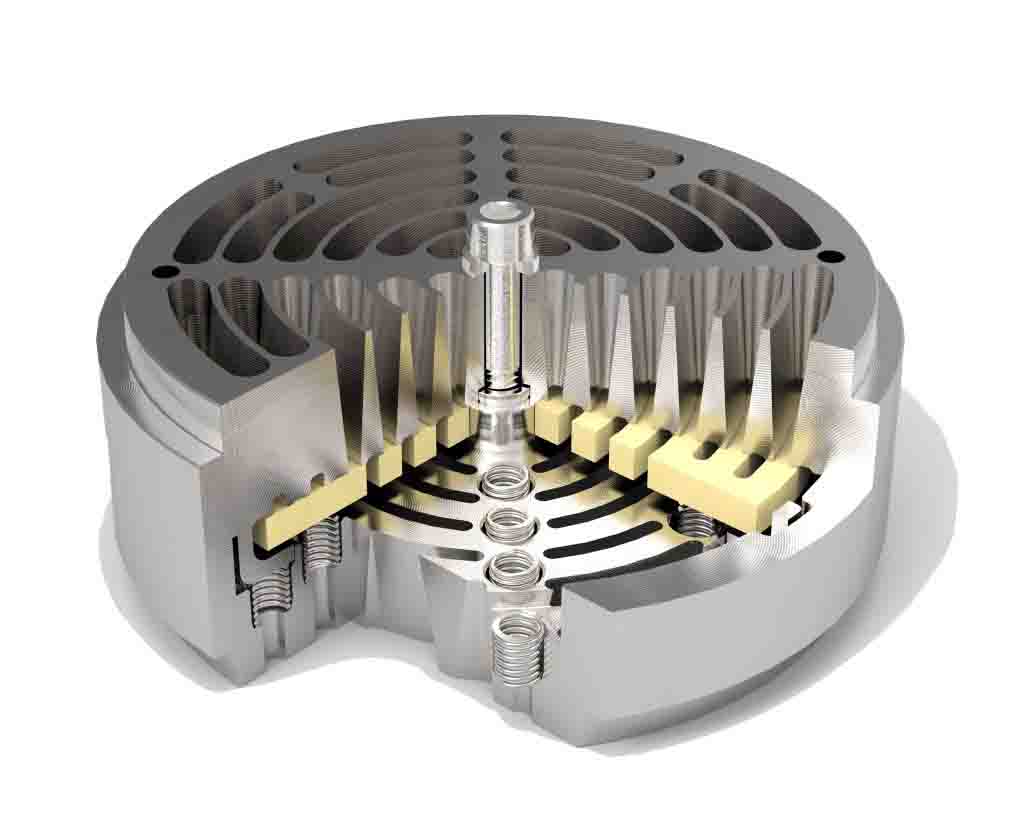

What is PEEK Valve Plates?

The valve plate is a key component in reciprocating compressors with a direct impact on their efficiency and reliability. When steel – with its significantly shorter service life – is used, steel splinters could cause serious damage to the cylinder, piston and piston ring if the valve plate breaks. The use of durable PEEK plates will avoid such asset losses in the future and will provide end users in the oil and gas industry or in fertiliser production plants with a noticeable added value by reducing downtimes and the associated costs.

The Effectiveness of PEEK Valve Plates

The use of reciprocating compressors has become a mainstay for most industries. They form not only a vital part of any pneumatic or gas line but also feature in areas like refrigeration as the key part of the equipment or appliance.

Like most equipment, we seek constantly to limit the failure and downtime. While the break-down of a compressor can seriously hinder operations within an industrial outfit, failure within a consumer appliance can be very problematic, as we usually do not expect the compressor in a refrigerator or air conditioner to fail during the life of the product. Furthermore, the replacement of the compressor is expensive and time-consuming.

Analysis of the durability of this equipment yielded the failure of the compressor valve plate as one of the main causes of the breakdown.

The compressor valve plate sits at the heart of the reciprocating arrangement and is responsible for taking a lot of the loads associated with the compressor function. In addition to this, it is in direct contact with the air, gas or fluids running through the compressor and is subject to both corrosive forces as well as high pressures and temperatures.

ZECO valve manufactured and supplied PEEK Seat ball valve and we strive to provide with high-quality, specialty ball valve as quickly and efficiently as possible.

Related Tags :

Ten articles before and after