What is Eccentric Ball Valve?

Eccentric semi-ball valve and flange valve belong to the same type of valve, but the difference is that the closure member of an eccentric semi-ball valve is a sphere and this sphere can rotate around the center line of the body to achieve the open and close movement. Ball valves are mainly used for cutting, distribution, and changing the direction of the media flow in pipeline applications. Two-piece ball valves and three-piece ball valves are new kinds of valves that have been widely used in recent years.

Specifications of Eccentric Ball Valves

The semiball valve is also called an eccentric plug valve, which is designed by metal to metal hard seated and double flanged type. It is applied in the sewage and wastewater industry, municipal engineering, drinking water engineering, etc.

- Flange dimension and drilling: EN1092/ISO5752(DIN2501), or other as request

- Face-to-face length: EN558-1/ISO5752 series 3(DN300 and bigger size, enterprise standard)

- Pressure rating: PN 10/16/25/40/64

- Sizes: DN 100 – DN 2000;4″-80″

- Applications: water, wastewater, oil, grain, slurry, etc.

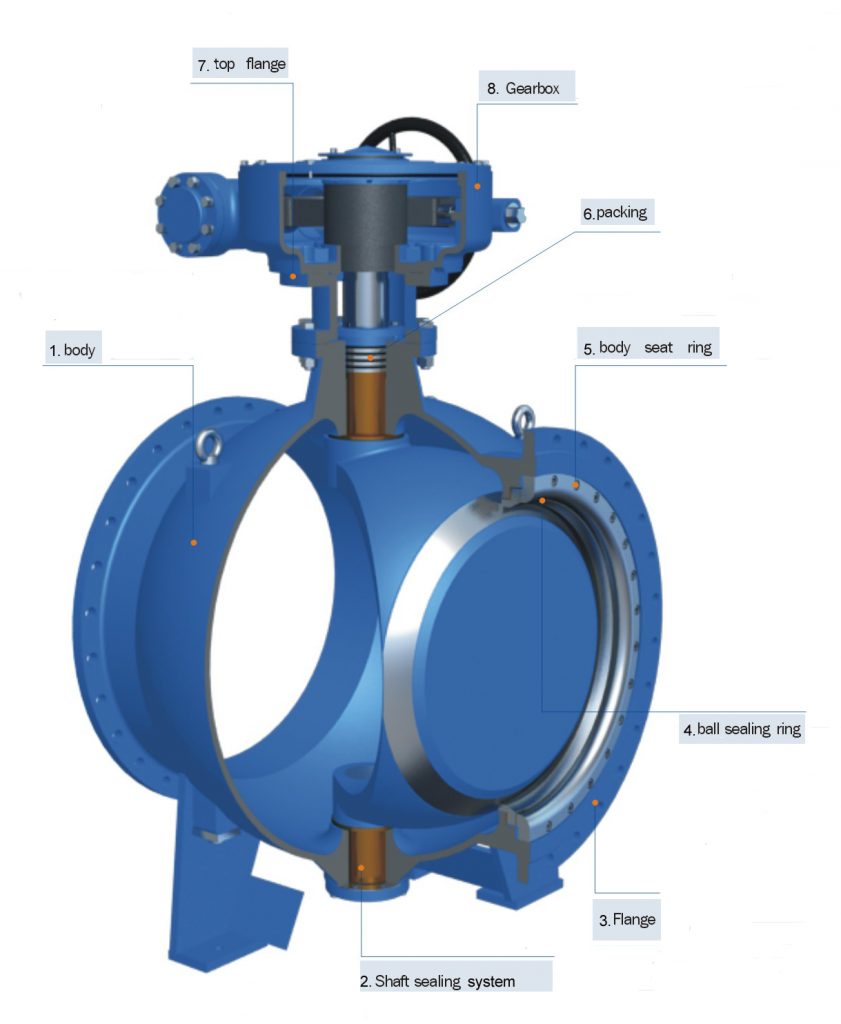

- Body

- Straight-through flow port with low-pressure loss and energy-efficient

- Shaft sealing system

- Shaft sealing by means of O ring or graphite packing ensures reliable sealing performance.

- Flange

- Flange and drilling with EN1092-2

- Ball sealing ring

- Welded hard alloy ball sealing ring provides long and durable service life.

- Body seat ring

- Welded hard alloy body seat ring provides long and durable service life.

- Packing

- Easily adjusted packing design ensures the reliable sealing performance

- Top flange

- ISO 5211 top flange connects with the gearbox

- Gearbox

- The gearbox is equipped with ISO 5210 flange connection with the actuator, and F10 is standard specified.

What’s the Eccentric semi-ball valve used for?

The eccentric semi-ball valve is consist of the valve body, eccentric shaft, valve cover, semi-ball, bushings, valve seat, and other parts, it rotates the eccentric shaft by 90 °to open/close the valve to cut off the medium, suitable for sewage disposal, petroleum, chemical, electricity and paper industries processing of slurry, slurry ash, paper pulp, alumina and other sealing tightness occasions, especially in two-phase flow medium. According to its installation structure, the eccentric semi-ball valve can be divided into a top entry eccentric semi-ball valve and a side entry eccentric semi-ball valve.

The design of the eccentric ensures no friction between the valve seat and semi-ball during opening or closing, extending the valve serving life. There is a certain eccentricity between the rotation of the eccentric axis and the center of the valve body, that is, the half-ball changes the axial displacement with the change of angular displacement when it is opened and closed so that they are in a linear proportional relationship, and its motion path is a semi-parabolic trajectory. The trajectory of the hemispheric body from the lowest point to the highest point automatically wedges the seat, and the seat also automatically generates a preload depending on the elastic modulus of the material to close tightly.

Eccentric semi-ball valve provides many advantages like simple structure, lightweight, small resistance and torque, tight sealing, and easy online maintenance, just open the valve cover and take out the eccentric shaft. The semicircular port has good flow performance and linear regulation performance, and impurities will not be deposited in the valve body cavity. In addition, she has the function of cutting, that is, in the closing of the media can be cut off debris, to ensure the normal opening and closing of the valve. The semi-ball and seat of the valve can be surfaced with different alloys to meet the needs of different occasions.

Advantage of Eccentric Ball Valve

- 1 fluid resistance small, the drag coefficient with the same length of pipe.

- 2 has the advantages of simple structure, small volume, and lightweight.

The Eccentric V Type Ball Valve position according to their channels can be divided into straight through, three links, and right angle type. After two kinds of ball valves for the distribution of media and a change in the flow of media. Three-piece ball valve installation and maintenance should pay attention to the following matters:

- 1 leave the position of the valve handle rotation.

- 2 can not be used for throttling.

- 3 belt drive mechanism of the valve should be installed upright.

Working principle of Eccentric Ball Valve

By rotating the valve to the valve flow or occlusion of the chain. Valve switch lights, small in size, can be made into a large caliber, reliable sealing, simple structure, convenient repair, sealing surface and spherical often in the closed state, the media can not easily be eroded, widely used in various industries.

Main Uses of Eccentric Ball Valve

Distribution and change the direction of media flow. The ball valve is a new valve that is widely used, it has the following advantages:

- 1 fluid resistance small, the drag coefficient with the same length of pipe.

- 2 has the advantages of simple structure, small volume, and lightweight.

- 3 closely reliable, valve sealing surface material widely used plastic, good sealing performance, in the vacuum system has also been widely used.

- 4 operation is convenient, quick open and close, from fully open to fully closed as long as the rotation is 90 °, and facilitates remote control.

- 5 ball valve has the advantages of simple structure, convenient repair, seals are generally activities, and the removal of the replacement is more convenient.

- 6 in the fully open or fully closed, the ball and seat sealing surface and the dielectric isolation, the medium through, will not cause erosion of the valve sealing surface.

- 7 is suitable for a wide range, from small diameter to a few Cast Steel Floating Ball valves, a few meters from the high vacuum, high pressure can be applied. The ball is rotated 90 degrees, in the inlet, the outlet should be a fully present sphere, thus cutting off the flow.

The eccentric semi-ball valve is a new type of ball valve type, it has some advantages of a unique structure of its own, such as the switch without friction, the seal is not easy to wear, hoist torque small. This reduces the actuator with the specifications. With multi-turn electric actuator, which can be realized on the media regulation and tight shutoff. Widely used in petroleum, chemical industry, city water supply, and drainage are strict cut-off conditions.

Structure Form of Eccentric Ball Valve

The eccentric semi-ball valve in the appearance of the structure is divided into two:

- 1 jacket type: mainly for erosion wear a very serious medium, upper structure in replaced repair damaged headstock piece is very convenient, need not put the entire valve removed from the pipeline, which greatly saves the time and cost of repair.

- 2 side mounted: side-mounted valve compact structure, lightweight, suitable for valve installation space requirements of the occasion.

Characteristic of Eccentric Ball Valve

The eccentric semi-ball valve is a jacket-type structure. Can be directly online inspection and repair of the valve installed in the pipe, can effectively reduce the plant parking, and reduce costs.

The eccentric semi-ball valve is a single-seat design. Remove the valve in the cavity medium affected by abnormal use boost security problems.

The low torque design. Special structural design of the stem, just with a little hand to easily open and close the valve.

They open and close without friction. This function completely solves the traditional [wiki] [/wiki] valve sealing surface due to friction between the sealing problems.

The wedge-shaped seal structure. The valve stem is provided by the mechanical force, the ball seat on the wedge pressure to seal, the valve seal is not affected by the impact of changes in pipeline pressure, and the sealing performance under various conditions has a reliable guarantee.

Self-cleaning structure and eccentric semi-ball valve sealing surface. When the ball roll away from the valve seat, fluid in the pipeline along the sealing surface of the sphere into 360 DEG, not only eliminates the high-speed fluid to seat local scour, but also washed away the accumulation on the seal face, to achieve self-cleaning purposes.

Related Tags :

Ten articles before and after

Automatic Control Valve(Pneumatic Actuator) | Zecovalve Blog

Automatic Control Valve | Zecovalve Blog

Connection Lift Plug Valve | Zecovalve Blog

High Performance Butterfly Valve | Zecovalve Blog