Control valves form a crucial part of the efficient and effective operation associated with a pipeline system.

What are Automatic Control Valves?

Automatic control valves, as described by EN 1074-5: “have the integral capability to control the function using energy from the conveyed water by adjusting the position of the obturator. They can be directly operated, i.e. the force is applied (via a spring or diaphragm) directly to the obturator. They can be pilot operated, i.e. the force is applied through an adjustable pilot valve”.

How does an Automatic Control Valve work?

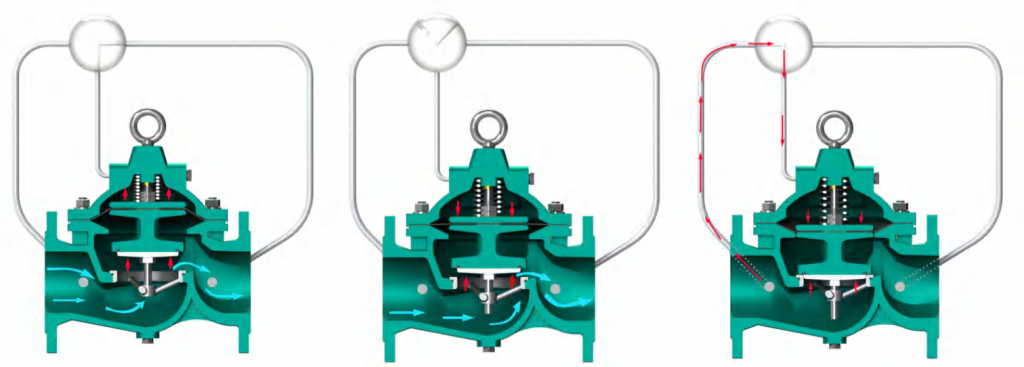

Principle of Automatic Control Valves for On/Off Operation

Valve Opening

If the pressure inside the control chamber is put in communication with the atmosphere or some other lower pressure zone, the upstream pressure will act on the obturator, pushing it upwards allowing the complete opening of the valve.

Valve Isolated From the Line

Should the control chamber be isolated from the line pressure and the rest of the circuitry the valve will remain in the same position, therefore producing the head loss corresponding to such opening percentage.

Valve Closing

If the control chamber is put in communication with the upstream pressure, thanks to the difference in the area between the upper flat with the diaphragm, larger than the obturator underneath, the valve will close completely.

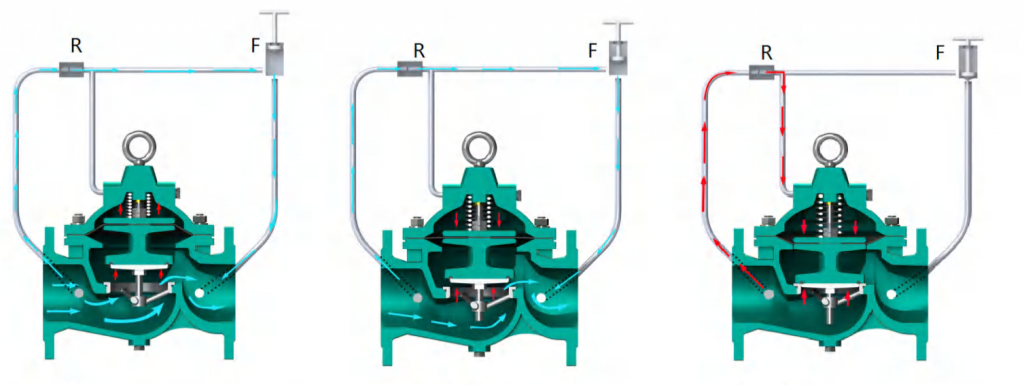

Principle of Automatic Control Valves for Modulating Operation

Valve Opening

When the main valve is required to modulate a restriction (R) is needed between the upstream line pressure and the control chamber, in addition to a regulator (F) on the circuit. Should the latter open completely pressure inside the control chamber will be put in communication with downstream, allowing for the full opening of the main valve.

Valve Modulating

If the flow regulator (F) is throttled pressure will build up between it and the control chamber, causing the valve to modulate accordingly to an intermediate position. This is obtained thanks to the pressure difference created by the restriction (R) and to the difference in the section between the upper flat acting on the diaphragm and the obturator.

Valve Closing

Should the flow regulator (F) be completely closed, the upstream line pressure is all diverted to the main control chamber. The mobile block is moved by the force exerted on the upper diaphragm flat pushing the obturator down onto the seat, interrupting the flow through the main valve.

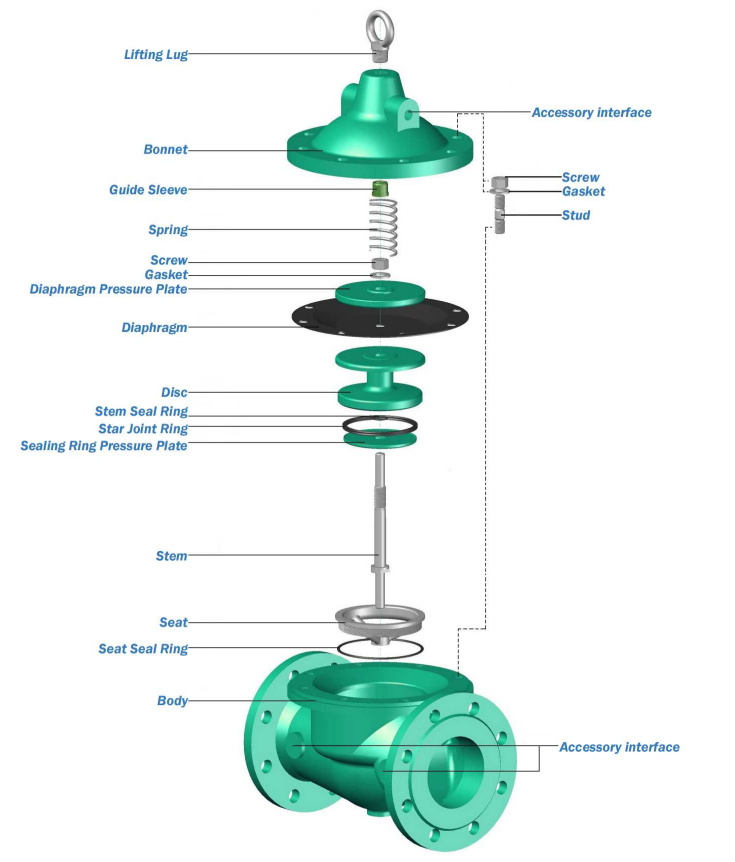

Components of an Automatic Control Valve

Applications of Automatic Control Valves

- Water treatment plants

- Multi-story buildings

- Water storage towers

- Reclaimed water systems

- HVAC Systems

Types of Automatic Control Valves

Pressure Reducing Valves

Pressure reducing valves can reduce higher inlet pressure to a constant downstream pressure regardless of demand and supply pressure fluctuations and enable the delivery of water at safe pressures and adequate levels for customer needs.

Pressure Relief Valves

Pressure relief valve can relieve excess pressure while maintaining a minimum upstream pressure and prevent downstream demand from sacrificing the supply of an upstream zone.

Altitude Control Valves

Altitude control valve is designed to open, allowing flow into a reservoir or elevated storage tank (tank fill), and close drip tight when a high water level is achieved. It controls water level by remotely sensing static tank head pressure through a field-installed sensing line, opens when the water level is below the adjustable set-point, and closes drip tight when the level is above the adjustable set-point.

Remote Float Control Valves

Remote float control valve is designed to close drip tight when the water level reaches the adjustable high-level set-point, and open fully when the water level is below the adjustable low-level set-point to increase tank circulation. High and low levels are separately adjustable by positioning stop collars on the float rod(s) at the desired opening and closing set-points. If desired, the on-off action of the valve can be reversed by modifying the hydraulic connections of the On-Off Float Pilot. The Float Pilot may be either valve or remote mounted.

Surge Anticipating Valves

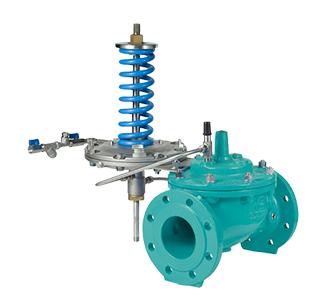

Surge Anticipating Valve is an off-line, hydraulically operated, diaphragm actuated valve. The valve, sensing line pressure, opens in response to the pressure drop associated with abrupt pump stoppage. The pre-opened valve dissipates the returning high-pressure wave, eliminating the surge. The surge anticipating valve smoothly closes drip tight as quickly as the relief feature allows while preventing closing surge. The valve also relieves excessive system pressure.

Solenoid Control Valves

Water solenoid valves are the most frequently used control elements in fluidics. Their tasks are to shut off, release, dose, distribute or mix fluids. They are found in many application areas. Solenoid valves offer fast and safe switching, high reliability, long service life, good medium compatibility of the materials used, low control power, and compact design.

Flow Control Valves

Flow control valve prevents excessive flow by limiting flow to a preselected maximum rate, regardless of changing line pressure. They are hydraulically operated, pilot-controlled, diaphragm valves. The pilot control responds to the differential pressure produced across an orifice plate installed downstream of the valve. Accurate control is assured as very small changes in the controlling differential pressure produce immediate corrective action of the main valve. Flow rate adjustments are made by turning an adjusting screw on the pilot control.

Advantages of Automatic Control Valves

- Full-through radial streamlines design, small fluid resistance, large flow, and strong anti-cavitation ability.

- The sealing ring adopts an advanced star-shaped sealing ring structure.

- Removable stainless steel 304 valve seat, corrosion resistance, erosion resistance, good sealing performance.

- The diaphragm is made of nylon reinforced rubber, with three-dimensional mesh, good elasticity, high-pressure resistance, and long service life.

- Different Pilot valves are available to achieve different functions.

- Pressure Rating: 10bar, 16bar, 25 bar; CL150,CL300

- End Connections: Standard Flange Ends To EN1092, ASME B16.5, and others on Request.

Related Tags :

Ten articles before and after

SELECT CONTROL VALVES I – Zeco Valve | Industrial valve manufacturer

HOW YOU CAN SELECT CONTROL VALVES II – Zeco Valve | Industrial valve manufacturer

Use and Maintenance of Ball Valves Used for Gas Pipes – Zeco Valve | API approved valve manufacturer

HOW YOU CAN SELECT End-Suction Pumps – Zeco Valve | Industrial valve manufacturer

GOOD REPUTATION FOR SPLIT-CASE PUMPS – Zeco Valve | Industrial valve manufacturer

LET US DISCUSS AIR-OPERATED DIAPHRAGM PUMPS – Zeco Valve | Industrial valve manufacturer

HISTORY OF SAFETY VALVES ON HANDS-FIRED BOILERS – Zeco Valve | Industrial valve manufacturer

A BRIEF HISTORY OF METERING PUMPS – Zeco Valve | Industrial valve manufacturer

THE FOUNDATION FROM THE PRESSURE RELIEF VALVE – Zeco Valve | Industrial valve manufacturer