Gate valves and globe valves are two of the most common valves used in industrial applications. Both contribute greatly to any industrial services. They may look alike but these valves function differently. In this article, you will know what makes the gate and globe individually unique as well as the major differences between the two valves.

What is a Gate Valve?

Gate valves are linear valves belonging to the shutoff valve family. Characterized by its wedge-like disc, the gate valve is commonly used for isolating media because of can tightly seal off media. This kind of valve can be used in applications where tight sealing is required. A special kind of gate valve, knife gate valve, is used in thicker and more viscous media.

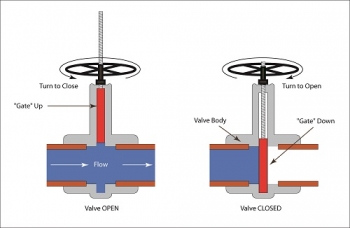

Gate valves provide little pressure drops since no obstruction comes in the way of media flow. The gate operates by the gate disc moving upwards to open the valve. It closes by moving the disc downwards to meet with the seats. The disc of the gate valve can be formed like a wedge, knife, or parallel.

While it does have some throttling capacity, the gate valve is not used to regulate the flow of media. Its disc is thin so the vibration from the media causes this thin disc to misalign from its seat. This condition causes damage and shortens its service life. To lengthen the valve life, the gate valve should fully open or fully close when in use.

What is a Globe Valve?

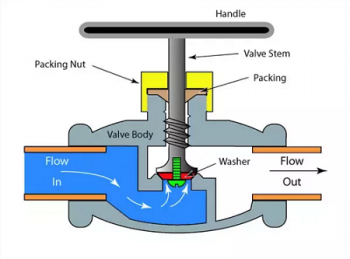

The globe valve is also a member of the linear motion valve family. Its functions include stopping and starting media as well as regulating the flow of media. Because of its design, the globe valve provides a tight seal with fewer chances of leakage.

The globe valve is aptly named as such because of its traditional body design similar to that of the globe. But as one gate valve China manufacturer would tell you, however, modern globe valves may adapt to other body shapes. A plug-like disc allows or prohibits the flow of media.

The seats of the gate valve are parallel to the flow of the media so there is less seat erosion when the valve is on. This also makes the globe valve a great throttling valve. The downside is, that there is a high-pressure drop because of its design.

If you look at the image above, you’d notice that the valve forces the media to change its flow direction exactly inside the valve. Additionally, the media flow inside the valve depends on the space between the seat and the disc. The farther these are, the more fluid comes in.

Globe valves are highly suitable for applications where safety and leaks are the main concerns. These valves are often in top-entry design, meaning, access to the internal components of the valve is from the top.

Gate Valve vs Globe Valve

There is always a comparison between the gate valve and the globe valve. Members of the linear valve family, you’d find these two in tandem in pipe systems. How would you use these two? Look at the differences between the two below:

Working Principles:

Whenever the globe valve opens and closed, the valve stem is lifted, i.e., as the handwheel is rotated, the handwheel rotates and lifts along with the valve stem. The gate valve rotates the handwheel to allow the valve stem to go up and down, and the position of the handwheel does not alter.

The gate valve only has two states that are completely open or completely shut. The opening and closing strokes of the gate is quite wide and the opening and closing time is very long; the movement of the valve plate of the globe valve is much shorter and the valve plate of the globe valve will stop at a certain position during movement. For one, it is used for flow adjustment, while the gate valve can only be used for shut-off and has no other function.

Application:

Globe valves are used for applications where huge changes in pressure are not important. This is while gate valves are usually used where even low-pressure drops are very important. Another difference in the application between these two valves is that gate valves are multi-directional, while globe valves are unidirectional.

Function:

The gate valve is not designed for flow control; it is for the isolation of media. The gate valve cannot handle the strength of the media flowing in a partially opened position. On the other hand, the globe valve is more of a control valve.

Structure:

The structure of the gate and globe valves is another difference. The globe valve is more complicated than the gate valve. The body top contains many of the internal parts of a gate valve. They can have a rising stem or a non-rising one. The valve turns on, and the body evolves open. This is why the pressure drop is so low. Globe valves are more complex because their inner parts are within the cavity. The globe valve’s primary function is to deliver positive shutoff and throttle. Globe valves can also be used to change flow direction or flow rate, which can cause high-pressure drops.

Price:

Because of their simplicity, gate valves can be more affordable than globe valves of the same size.

The Overall Difference Between Gate Valve and Globe Valve

Gate valves are linear valves and belong to the family of shut-off valves. They have a wedge-like disc. Because of their ability to provide tight seal-off, they are usually used for isolating media. When there are thicker media involved, a special kind of gate valve known as a knife gate valve is used to provide tight sealing. The gate valve disc can be formed like a knife, wedge, or parallel. As mentioned above, they provide little pressure drop because the media flow comes across with no obstruction.

When the disc moves upward, the valve is in the open position and starts to operate. When the disc moves downward and reaches the seats, it is in the closed position and the flow stops.

Gate valves are usually not used for regulating the media flow. Because of its thin disc, the vibration of the media movement causes the disc to misalign from the seat which causes damage and a constant need for services.

Globe valves, as well, are among the linear motion valve family. They are used for stopping and starting the media flow. They can also regulate the media flow as well. They provide tight shut-off and a low chance of leakage. When safety and leaks are among the main concerns, globe valves should be your go-to.

Globe valve seats are parallel to the media flow and because of this movement, there is less seat erosion in the open position. They are also considered great throttling valves. As mentioned above, due to their design, they have high-pressure drop which is considered a down point.

Quick Comparison of Globe Valve vs Gate Valve

- Globe valves are usually used for flow regulation, while gate valves are often used for on-off control.

- Gate valves are cheaper than globe valves.

- Gate valves have little pressure drop across the valve and provide little resistance to the media flow in the open position. Globe valves, on the other hand, provide substantial resistance to the flow of the fluid and have high-pressure drops.

- Gate valves have a simple design, whereas globe valves have a complex design.

- Gate valves are unidirectional while glove valves are multi-directional.

- Gate valves provide little fluid trapping in the line but globe valves trap a larger amount because of their flow direction.

How To Choose Between Globe Vs Gate Valve

There are a few factors to consider when deciding whether to use a globe valve or a gate valve. The first is the type of media that will be flowing through the valve. If you’re handling a liquid, then a globe valve is typically the better choice. If you’re dealing with gas, then a gate valve may be a better option. The second factor to consider is pressure. Globe valves can handle higher pressures than gate valves, so if you’re working with high-pressure media, then a globe valve is the way to go. Finally, you’ll need to decide what size valve you need. Globe valves come in a range of sizes, from small valves that can handle a few liters per minute to large valves that can handle hundreds of liters per minute.

A fascinating facet of valves is that they may look the same but they can function quite differently. This remains true in the case of gate and globe valves. If you are seeking an industrial valve supplier, you can choose a manual operate gate valve manufacturer in the USA or ZECO in China. Or you can also get the great manufacturers in this complete valve manufacturers guide in China.

Related Tags :

Ten articles before and after

Top 8 Gate Valve Manufacturers in the USA – Zeco Valve

Best 10 Gate Valve Manufacturers in India – Zeco Valve

Intro to Lug and Wafer Type Butterfly Valve

Have you paid attention to these thing of cryogenic valves

Choose between bronze and brass valves

Knife Gate Valve vs. Gate Valve

How Does a Gate Valve Work? – Zeco Valve