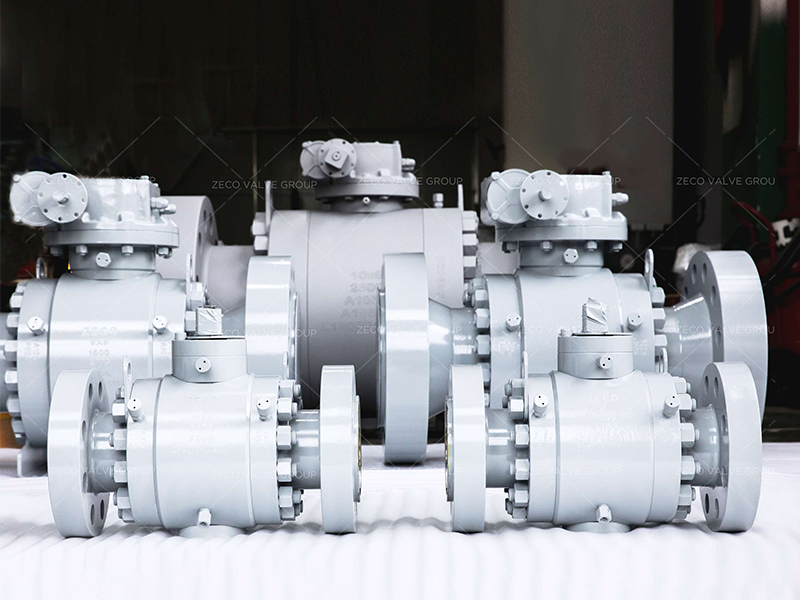

Forged Steel Trunnion Ball Valve

Categories: Ball Valve, Ball Valve By Material

Tags: API 6D Ball Valve, Isolation Valve, Reduced Bore Ball Valve, What is a Valve

Description

Forged steel trunnion mounted ball valve has been designed two piece body type or three piece body type and with two floating seats, which are movable under the pressure of medium.

What is Trunnion Ball Valve?

A ball valve uses a rotating ball and a stem to provide on/off flow control. When the valve is positioned where the bore is aligned in the same direction as the pipeline, it is in the open position, and fluid can pass downstream. When the ball is rotated 90-degree, the bore becomes perpendicular to the flow path, meaning the valve is closed, and fluid cannot pass. Advantages of a ball valve include Fast shut off, only a 90-degree turn is required to close the valve. The opened or closed state of the valve can be easily detected by the position of the handle. The Ball Valve provides a tight seal, even after long periods, utilizing soft sealing components. Trunnion-mounted ball design features a “trunnion” anchoring at the top and bottom of the ball. This design provides a positive seal on both downstream and upstream seats, regardless of pressure, allowing for Double Block and Bleed, or Double Isolation and Bleed function. This makes trunnion design ball valves suitable for larger-bore and higher-pressure operations. Additionally, this design reduces the torque required to stroke the valve, making a trunnion design ideal for automated ball valve applications.Specifications of Forged Steel Trunnion Ball Valve

ZECO trunnion mounted ball valves feature a full line product offering with valves ranging in 2″-56″, ANSI classes 150LB – 2500LB, forged steel bolted or all welded body, close coupled trunnion block design for low operating torques, and secondary seat sealant feature. API-6D valves are offered with self-relieving seats or optional double piston sealing. Special seat compounds are also available. Each valve meets, API-6D, API 6FA, and Nace requirements. Options include stem extensions, actuators, pipe pups, and specialized coatings.- Certification: ISO9001, API6D, CE, TS

- Size: 2″-56″

- Pressure: Class 150LB-2500LB

- Material: A105, LF2, F11, F22, F5, F304, F316, F304L, F316L

- Guarantee: 12months

- Suitable medium: water, oil, gas

- Design and Manufacture: API6D, ASME B 16.34, BS5351

- Inspection and Test: API598

- End flange dimension: ASME B16.5 (for NPS≤24); AMSE B16.47 series B

- Socket-weld dimension: ASME B16.11

- Face to face and end to end: ASME B 16.10

- Pressure/temperature rating: ASME B16.34

Working Principle of Forged Steel Trunnion Mounted Ball Valve

Under the bottom of seats, seat pre-loading springs are positioned to ensure two floating seats can attach to the ball’s surface tightly, other more, the pressure of medium also can push seats to attach the ball tightly to ensure sealing is more reliable. Ball valves are widely used in petroleum refining, chemical, paper making, pharmacy, food, water power, municipal, steel, and other industries. Among them, sulfur-resistant series ball valves are particularly suitable for long-distance pipelines for transmission of high-corrosion natural gas with sulphuret hydrogen medium and many impurites. The trunnion ball valve is equipped with a movable seat seal ring which can generate displacement under the pressure of medium. In case that any medium pressure exists, the pressure will press the valve seat seal ring onto the ball tightly, guaranteeing the sealing performance of the ball valve.Features of Forged Trunnion Ball Valve

- 1. Simple structure with good sealing performance and small torque;

- 2. Full bore and reduced bore design with the minimum flow resistance (zero actually);

- 3. Emergency sealant injection;

- 4. Independent ball and stem;

- 5. Low emission packing;

- 6. Fire safe, anti-static, and anti-blowout stem design;

- 7. Cavity pressure self-relief;

- 8. Optional extended bonnet。

Shipping Information of Forged Steel Trunnion Ball Valve

| Brand | ZECO |

| Valve Type | Forged Steel Trunnion Ball Valve |

| Valve Material | forged steel, stainless steel, etc |

| Valve Test | 100% quantity tested before delivery |

| Valve Guarantee | 18 months from the date of dispatch ex-works, or 12 months from the date of commodity installation. |

| Valve Painting | Customer request |

| Valve Package | Wooden case |

| MOQ | No requirement |

| Valve Certificate | API 6D/CE/ISO9001/ISO14001 |

| Delivery Detail | Shipped in 4 or 6 weeks after payment |

| Port | SHANGHAI, NINGBO |

| Payment Terms | L/C, T/T |

| Certificate Offered | Packing List, Commercial Invoice, Test Reports, and Material Certificates, Certificate of quality and quantity, Seller’s Certificate of Guarantee |