Ever wonder why your basement doesn’t flood when your sump pump turns off? Or why contaminated water doesn’t flow backward into your clean water supply?

The answer? Check valves.

What do check valves do? They’re mechanical devices that allow fluids to flow in only one direction while automatically preventing backflow in the opposite direction. Think of them as one-way gates for liquids and gases.

I’ve spent years working with various valve systems, and here’s the thing: check valves are everywhere. From your home’s plumbing to massive industrial facilities. Yet most people have no clue how critical they are.

In this guide, as a professional check valve manufacturer, I’ll break down exactly how these check valves work, why they’re essential, and how to choose the right one for your needs.

Table of contents

- The Core Function: Preventing Backflow

- How Check Valves Actually Work

- 4 Critical Applications Where Check Valves Save the Day

- Types of Check Valves (And When to Use Each)

- The Biggest Mistake People Make with Check Valves

- How to Choose the Right Check Valve

- Installation Tips That Prevent 90% of Problems

- Real-World Performance Data

- Troubleshooting Common Check Valve Problems

- The Future of Check Valve Technology

- The Bottom Line

The Core Function: Preventing Backflow

Here’s the deal:

The primary job of a check valve is preventing backflow. And backflow can be a massive problem.

For example, I once consulted for a water treatment facility that experienced contamination because of a faulty check valve. The cleanup cost? Over $2 million.

But it’s not just about contamination.

Backflow can:

- Damage expensive equipment (like pumps and compressors)

- Cause water hammer that can burst pipes

- Mix incompatible fluids in industrial processes

- Drain systems that need to stay primed

Think about it this way: without check valves, every time you turned off a pump, fluid would rush backward through the system. That’s a recipe for disaster.

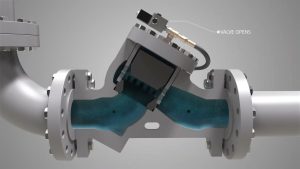

How Check Valves Actually Work

Check valves are surprisingly simple. And that’s what makes them so reliable.

Here’s how they operate:

When fluid flows in the intended direction, pressure pushes the valve’s internal mechanism (usually a disc, ball, or flapper) open. The fluid passes through freely.

But when flow stops or reverses? The pressure differential immediately forces the valve closed.

No electricity needed. No manual operation. Just pure physics.

The best part? This happens automatically. The valve responds instantly to changes in flow direction.

The Pressure Game

For a check valve to open, you need something called “cracking pressure.” This is the minimum upstream pressure required to overcome the valve’s closing mechanism (usually a spring or the weight of the disc itself).

Different applications need different cracking pressures. A low-pressure water system might need a valve that opens with just 0.5 PSI. But a high-pressure hydraulic system might require 5 PSI or more.

4 Critical Applications Where Check Valves Save the Day

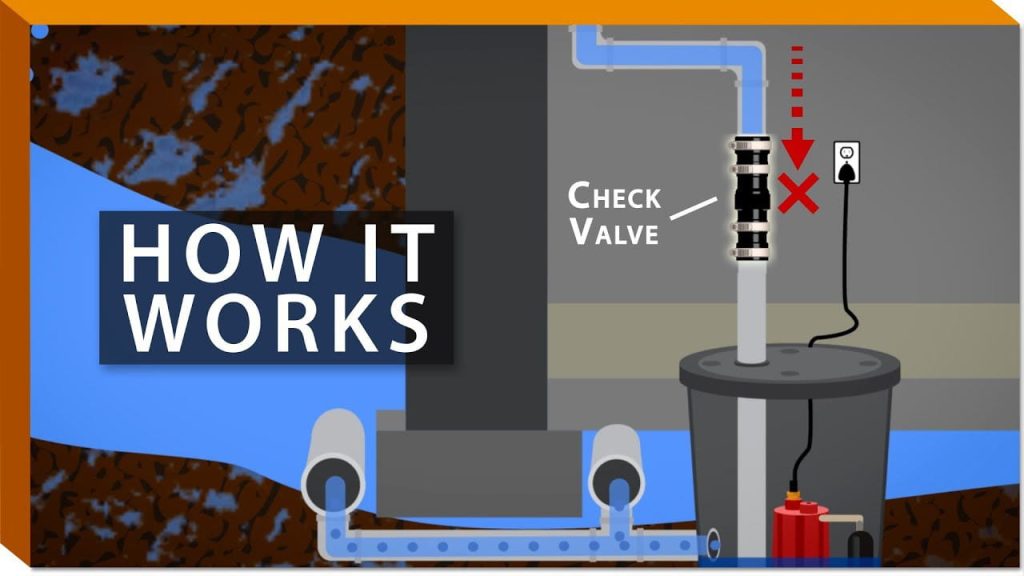

1. Protecting Pumps from Damage

This is huge.

When a pump shuts off, the fluid in the discharge line wants to flow backward. Without a check valve, this reverse flow can spin the pump impeller backward, potentially destroying it.

I’ve seen pumps worth $50,000+ destroyed because someone removed a “problematic” check valve. (Spoiler: the valve wasn’t the problem – it was incorrectly sized.)

2. Preventing Water Contamination

In water systems, check valves are literally lifesavers.

They prevent contaminated water from backflowing into clean water supplies. This is especially critical in:

- Municipal water systems

- Hospitals

- Food processing plants

- Residential plumbing

One failed check valve in a municipal system can affect thousands of people. That’s why many jurisdictions require regular testing of these valves.

3. Maintaining System Pressure

Ever notice how your home’s water pressure stays consistent even when the well pump cycles off?

Thank a check valve.

These valves keep pipes full of fluid when pumps shut down. This maintains system pressure and keeps pumps primed for the next startup.

4. Mitigating Water Hammer

Water hammer is no joke.

When fluid suddenly stops flowing (like when a valve slams shut), it creates a shockwave that can:

- Burst pipes

- Damage equipment

- Create noise that sounds like someone’s hitting pipes with a hammer

The right check valve can control flow deceleration, significantly reducing these pressure surges.

Types of Check Valves (And When to Use Each)

Not all check valves are created equal. Here are the main types you’ll encounter:

Swing Check Valves

These use a hinged disc that swings open with forward flow.

Pros:

- Simple design

- Good flow capacity

- Easy to maintain

Cons:

- Only work horizontally

- Slow closing (prone to water hammer)

- Don’t seal well with low back pressure

Best for: Large diameter pipes with steady flow

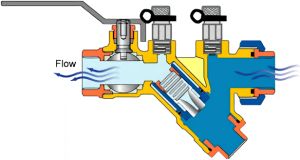

Spring Check Valves (In-Line/Piston)

These use a spring-loaded disc or poppet in line with the flow.

Pros:

- Fast closing (prevents water hammer)

- Work in any orientation

- Excellent for vertical installations

Cons:

- Higher pressure drop

- Not suitable for dirty fluids

Best for: Clean fluids, pump discharge, vertical pipes

Ball Check Valves

A free-floating ball moves between the seat and a retainer.

Pros:

- Self-cleaning (ball rotates)

- Good for viscous fluids

- Simple design

Cons:

- Limited to smaller sizes

- Can be noisy

Best for: Viscous fluids, small diameter pipes

The Biggest Mistake People Make with Check Valves

Here’s what drives me crazy:

People select check valves based on pipe size alone.

Big mistake.

A 4-inch pipe doesn’t automatically need a 4-inch check valve. You need to consider:

- Flow rate

- Fluid velocity

- Pressure conditions

- Application requirements

I’ve seen countless failures because someone installed an oversized check valve. What happens? The valve never fully opens, causing it to chatter and fail prematurely.

How to Choose the Right Check Valve

Follow this process (it’s saved my clients millions in prevented failures):

Step 1: Calculate Your Flow Requirements

Don’t guess. Use actual flow data.

If your maximum flow is 100 GPM through a 4-inch pipe, you might only need a 3-inch check valve. Smaller valve = higher velocity = valve stays fully open.

Step 2: Consider Installation Orientation

- Horizontal flow? Most check valves work

- Vertical flow up? Need a spring-assisted design

- Vertical flow down? Requires specific valve types

Step 3: Evaluate Your Media

Clean water is easy. But what about:

- Fluids with particles? Avoid tight-clearance designs

- Corrosive chemicals? Material selection is critical

- High temperature? Standard elastomers won’t work

Step 4: Determine Acceptable Leakage

Metal seats allow some leakage. If you need zero leakage, you’ll need elastomer seats.

But remember: elastomers have temperature and chemical compatibility limits.

Installation Tips That Prevent 90% of Problems

After analyzing hundreds of check valve failures, here’s what I’ve learned:

Give It Space

Install check valves at least 10 pipe diameters downstream from pumps, elbows, or other flow disturbances.

Why? Turbulent flow causes premature wear.

Can’t get 10 diameters? Even 5 is better than bolting it directly to a pump flange.

Check the Flow Arrow

Sounds obvious, right?

Yet I’ve seen experienced technicians install check valves backward. Always verify the flow arrow before installation.

Consider Accessibility

Will you need to inspect or maintain this valve? Don’t bury it behind other equipment.

Real-World Performance Data

Let me share some eye-opening statistics:

According to industry studies, properly sized check valves can:

- Reduce water hammer incidents by up to 87%

- Extend pump life by 40-60%

- Prevent 99.9% of backflow incidents (when properly maintained)

But here’s the kicker: improperly selected check valves fail 5x more often than correctly sized ones.

Troubleshooting Common Check Valve Problems

When check valves “fail,” it’s usually not the valve’s fault. Here’s what’s really happening:

Problem: Chattering or Noise

Cause: Oversized valve not fully opening

Solution: Downsize to match actual flow conditions

Problem: Excessive Pressure Drop

Cause: Undersized valve or partial opening

Solution: Verify flow calculations and resize accordingly

Problem: Leaking in Closed Position

Cause: Debris, wear, or incompatible seat material

Solution: Clean, replace worn parts, or upgrade seat material

Problem: Sticking Open or Closed

Cause: Corrosion, scale buildup, or wrong material selection

Solution: Regular maintenance or material upgrade

The Future of Check Valve Technology

The industry is evolving fast.

New developments include:

- Smart check valves with position monitoring

- Advanced materials for extreme conditions

- Designs optimized using computational fluid dynamics

- Integration with predictive maintenance systems

These innovations are making check valves more reliable and easier to maintain than ever before.

The Bottom Line

So, what do check valves do?

They’re your system’s silent guardians, preventing costly backflow problems 24/7 without any external power or control.

Whether protecting million-dollar pumps or preventing contamination in drinking water, check valves are essential components that work tirelessly behind the scenes.

The key to success? Don’t treat them as an afterthought. Proper selection, sizing, and installation will save you from headaches (and massive repair bills) down the road.

Remember: a $100 check valve can prevent $100,000 in damage. That’s an ROI any engineer can appreciate.