What is a Pinch Valve?

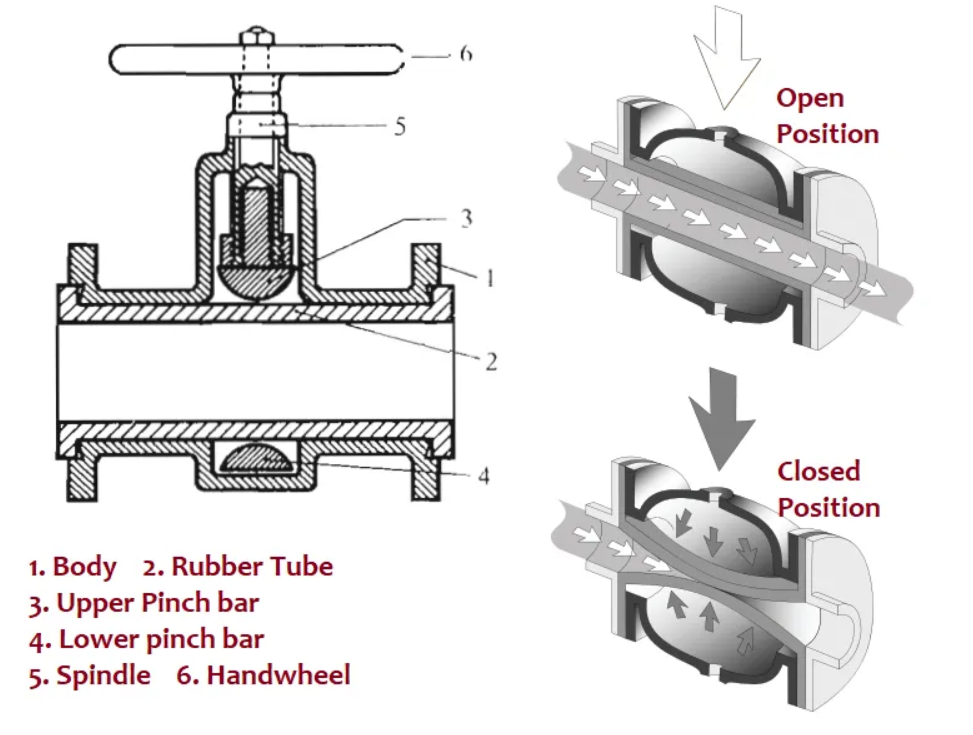

A pinch valve is a full bore or fully ported type of control valve which uses a pinching effect to obstruct fluid flow.

A pinch valve is a flex-body valve with a flexible tube that can be pushed together or “pinched” mechanically through a mechanism or through fluid pressure to create a full closure of the flow path. The flow passage of these valves is straight without crevices and moving parts. The soft body of the pinch valves has the ability to seal around the trapped solids.

How does a Pinch Valve work?

A pinch valve is a 2/2-way valve designed to shut off or control the flow of corrosive, abrasive, or granular media. It utilizes pressurized air to open or close the valve. In the open position, the valve has no restrictions and allows a wide range of media to pass through the bore. The flexible internal rubber sleeve in the valve keeps the media isolated from the rest of the valve, preventing contamination or damage to the valve’s other components. Figure 1 is an example of a pneumatic pinch valve.

Pinch Valve Advantages & Disadvantages

The pinch valve is the simplest valve design on the market and has many benefits over conventional type valves. Most other valve types are unable to handle fluids with high concentrations of solids due to the particles often jamming the metal parts and clogging up the valve. Pinch Valves are the complete solution for handling almost every media in even the most severe application specification with no metal or mechanical parts.

The flexible elastomer sleeve inside the Pinch Valve, which has been specially designed, forms an effective seal with a tight shutoff around trapped particles. In some applications, particles can become trapped in the seal of the disc or ball in other conventional valves such as ball valves or butterfly valves, resulting in the product not shutting off fully.

Rubber liners inside a Pinch Valve come in a range of different qualities of rubber making various areas of application, operating temperatures and lasting properties possible. The grade of the rubber is crucial to the lifetime and anti-abrasion characteristics of the Pinch Valve. Depending on the elastomer used, the pinch valve can be limited in operating temperature and pressure.

Advantages of Pinch Valve

- Low & easy maintenance

- Low weight

- No clogging or dead spots

- Compact, simple, robust & straight through design

- Very fast opening/closing times

- Less air consumption

- Self-cleaning

- Permanent seal with tight shutoff

- Minimal turbulence & friction

- No mechanical parts and no bearings, seals, or packing are required.

- Only one replaceable part (elastomer sleeve)

- Inexpensive with an extremely good Total Cost of Ownership.

Disadvantages of Pinch Valve

- The temperature range is limited

- Operating pressure is limited

- Not recommended for gases

Applications of Pinch Valves

Pinch valves are suited for use with slurries and granular products like sand, cement, gravel, textile fiber, carbon, powder, pellets, chipping, and glass fragments. These valves are cost-effective, reliable, and easy to use, making them desirable in various industrial applications.

ZECO Valve is the largest manufacturer and supplier of pinch valves and check valves and is the preferred supplier for municipalities and industrial plants worldwide.

Related Tags :

Ten articles before and after

Y Strainers LF2 Material Flange Ends 2500LB – Zeco Valve Company | Professional valve manufacturer

WHY USE A TRIPLE OFFSET VALVE? – Zeco Valve Company | Professional valve manufacturer

Keystone Butterfly Valve Figure 990 Type – Zeco Valve Company | Professional valve manufacturer

What is Flow Control Valve – Zeco Valve Company | Professional valve manufacturer

How to Select a Basket Strainer – Zeco Valve Company | Professional valve manufacturer