What is AS2129 Standard?

AS2129 flange originates from BS10 and has been metricated. In some cases, slightly larger bolt holes provide better clearance as metric bolts are specified in lieu of UNC bolts used by BS10. AS4087 is an update of AS2129, however, AS2129 is still widely used so it has not been deleted as a standard, however, it now only covers AS table D to H.

The most common flanging used in Australia in oil, gas, and mining is now ANSI flanging to ANSI B16.5. However, in general industrial, commercial, and waste/water industries AS2129 Table flanging is the most common. Increasingly European PN-rated flanges are also specified in BS4504 as well as AS4331 and EN 1092-1. BS4504 is now obsolete and is replaced by EN 1092 which is listed in British Standards as BS-EN 1092. EN 1092 evolved from DIN 2501 which became part of ISO 7005, then EN 1092 was created as the standard for DIN-based flanges. (BS4504 flanges were generally the same as the old DIN 2501 specification, but the new EN 1092 standard covers a wider range). EN 1092-1 is for steel flanges, EN 1092-2 is for iron flanges, EN 1092-3 is for alloy flanges, and EN 1092-4 is for aluminum alloy flanges. PN stands for Nominal Pressure and roughly equates to the number of bar i.e. the cold working pressure of PN10 is 10 bar. Ratings range from PN2.5 to PN420. The latest Australian standard AS4331 references this rating system (PN2.5 to PN420). AS4331 is a reproduction of ISO 7005 which is based on the American and European flange systems PN20, PN50, PN 110, PN 150, PN 260, and PN 420 steel flanges are “designed to be interchangeable” with flanges to American standards ANSI/ASME B16.5 and MSS SP44; they are not identical but are “deemed to comply” with dimensions specified in ANSI/ASME B16.5 and MSS SP44 as appropriate.

This Standard AS 2129—2000 was prepared by the Joint Standards Australia/Standards New Zealand Committee ME/1, Pressure Equipment Standard to supersede AS 2129—1994.

This Standard is the result of a consensus among representatives on the Joint Committee to produce it as an Australian Standard. Consensus means general agreement by all interested parties. Consensus includes an attempt to remove all objections and implies much more than the concept of a simple majority, but not necessarily unanimity. It is consistent with this meaning that a member may be included in the Committee list and yet not be in full agreement with all clauses of this Standard.

This Standard is derived from the British inch series flange Standard BS 10:1962, Flanges and bolting for pipes, valves and fittings. BS 10 was made obsolescent in 1970, however, it is still called up in British pressure equipment Standards. A 1992 survey of Australian industry showed that flanges in accordance with AS 2129 were still in great demand. As a result it was determined that AS 2129 should be revised and updated rather than being made obsolescent.

It is anticipated flanges to AS 2129 will remain in use for at least 50 years, particularly for replacement flanges. Consideration should be given to the use of alternative flanges, such as those to AS/NZS 4331, Metallic flanges (series), BS 4504, Circular flanges for pipes valves and fittings, (PN designated), ANSI/ASME B16.5, Pipe flanges and flanged fittings, and AS 4087, Metallic flanges for waterworks purposes.

The main changes in this edition are as follows:

- (a) Incorporation of Amendment No. 1 to the 1994 edition.

- (b) Deletion of Table C which is now covered in AS 4087.

- (c) Updated referenced documents.

Statements expressed in mandatory terms in notes to tables and figures are deemed to be requirements of this Standard.

The term ‘normative’ has been used in this Standard to define the application of the Appendices. A ‘normative’ appendix is an integral part of this Standard.

1.1 SCOPE

This Standard specifies requirements for circular flanges of nominal sizes DN 15 to DN 3000, inclusive, and their bolting for use on pipes, valves, fittings and other pressure-retaining equipment containing fluid at pressures up to 19 300 kPa and at temperatures in the range −200°C to +525°C.

These flanges are manufactured from carbon steel, carbon-manganese steel, alloy steel, stainless steel, grey iron, malleable iron, ductile cast iron*, or copper alloy.

This Standard is applicable to flanges for water, steam, compressed air, chemical and petroleum plants, hydraulic piping and where other Standards require compliance with this Standard.

This Standard is not intended to apply to flanges for water or waste water covered by AS 4087.

Flanges R, S and T are designated obsolescent and are not recommended for use in new equipment. They are retained to provide for the servicing of existing equipment that is expected to have a long working life. For new equipment, flanges R, S and T should be replaced with flanges to AS/NZS 4331, Parts 1 to 3, ANSI B16.5 or BS 4504 (series).

The history of AS 2129 flanges (and its predecessor BS 10) and the future use of these flanges is given in the Preface.

1.2 OBJECTIVE

The objective of this Standard is to provide guidance to manufacturers and users on the materials, manufacturing requirements and dimensions of circular flanges for use with existing or new equipment.

1.3 APPLICATION

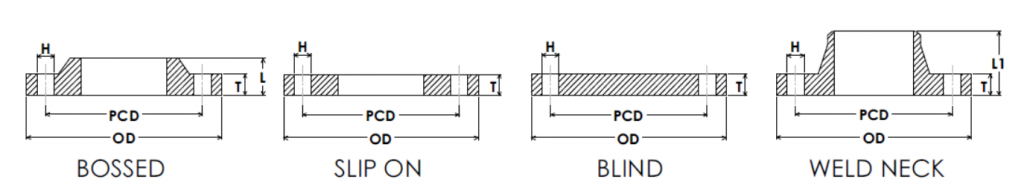

1.3.1 Flanges Flanges shall comply with the relevant requirements of this Section and with the specific requirements of the following Sections, as appropriate:

- Section 2 — Temperature/Pressure Ratings.

- Section 3—Materials.

- Section 4—Manufacturing Requirements and Dimensions.

- Section 5—Marking and Material Certificates.

- Section 6—Dimensions of Flanges.

1.3.2 Bolting Bolting for flanges shall comply with the requirements of Appendix A.

1.3.3 Assembly The assembly of flanged joints shall comply with the requirements of Appendix B.

1.4 REFERENCED DOCUMENTS

The documents referred to in this Standard are listed, with titles, in Appendix C.

| NOMINAL PIPE SIZE | NOMINAL PIPE SIZE | FLANGE OUTSIDE DIAMETER | THICKNESS OF FLANGE (Refer to Note.1) | BOSSED SOW | WELD NECK | PITCH CIRCLE DIAMETER | BOLT HOLE DIAMETER | BOLT HOLES |

| MM | INCH | OD | T | L | L1 | PCD | H | # |

| 15 | 1/2 | 95 | 5 | 15 | 27 | 67 | 14 | 4 |

| 20 | 3/4 | 100 | 5 | 16 | 27 | 73 | 14 | 4 |

| 25 | 1 | 115 | 5 | 16 | 27 | 83 | 14 | 4 |

| 32 | 1 1/4 | 120 | 6 | 17 | 31 | 87 | 14 | 4 |

| 40 | 1 1/2 | 135 | 6 | 19 | 35 | 98 | 14 | 4 |

| 50 | 2 | 150 | 8 | 21 | 37 | 114 | 18 | 4 |

| 65 | 2 1/2 | 165 | 8 | 24 | 40 | 127 | 18 | 4 |

| 80 | 3 | 185 | 10 | 26 | 45 | 146 | 18 | 4 |

| 90 | 3 1/2 | 205 | 10 | 27 | 45 | 165 | 18 | 4 |

| 100 | 4 | 215 | 10 | 29 | 51 | 178 | 18 | 4 |

| 125 | 5 | 255 | 13 | 32 | 57 | 210 | 18 | 8 |

| 150 | 6 | 280 | 13 | 32 | 61 | 235 | 18 | 8 |

| 200 | 8 | 335 | 13 | 35 | 64 | 292 | 18 | 8 |

| 250 | 10 | 405 | 16 | 43 | 80 | 356 | 22 | 8 |

| 300 | 12 | 455 | 19 | 48 | 89 | 406 | 22 | 12 |

| 350 | 14 | 525 | 22 | 95 | 470 | 26 | 12 | |

| 400 | 16 | 580 | 22 | 521 | 26 | 12 | ||

| 450 | 18 | 640 | 25 | 584 | 26 | 12 | ||

| 500 | 20 | 705 | 29 | 641 | 26 | 16 | ||

| 550 | 22 | 760 | 29 | 699 | 30 | 16 | ||

| 600 | 24 | 825 | 32 | 756 | 30 | 16 | ||

| 700 | 28 | 910 | 35 | 845 | 30 | 20 | ||

| 750 | 30 | 995 | 41 | 927 | 33 | 20 | ||

| 800 | 32 | 1060 | 41 | 984 | 36 | 20 | ||

| 850 | 34 | 1090 | 44 | 1016 | 36 | 20 | ||

| 900 | 36 | 1175 | 48 | 1092 | 36 | 24 | ||

| 1000 | 40 | 1255 | 51 | 1175 | 36 | 24 | ||

| 1050 | 42 | 1335 | 54 | 1251 | 36 | 28 | ||

| 1200 | 48 | 1490 | 60 | 1410 | 36 | 32 |

NOTES: (1) Plate Flanges less than 12mm in thickness may suffer unacceptable distortion after welding.

(2) Bore sizes to suit ASME B 36.10 pipe unless otherwise specified.

(3) Flanges are generally supplied flat-faced.

(4) All dimensions are in millimeters (mm)

Related Tags :

Ten articles before and after

Zeco Valve latest company news about pipe fittings forged butt weld | Quality valve supplier