Description

An axial check valve is a preferred solution for critical non-return applications such as the protection of rotating equipment and systems where low pressure loss, stable operation, and dynamic behavior are essential.

What is an Axial Flow Check Valve?

Axial flow check valves are a type of non return valve, designed to avoid the quick reverse of a flow in a pipe known as a “water hammer” that may cause severe damage to the different equipment of a piping system. This kind of valve close fast enough without creating excess pressure spikes, avoiding slamming.

The streamlined design of the axial flow check valve permits it’s fully opening at low flows and fluid velocities, getting a low pressure drop. Its spring assisted system and metal-to-metal sealing features provide a non-slam closing and little maintenance.

Working Principle of Axial Flow Check Valve

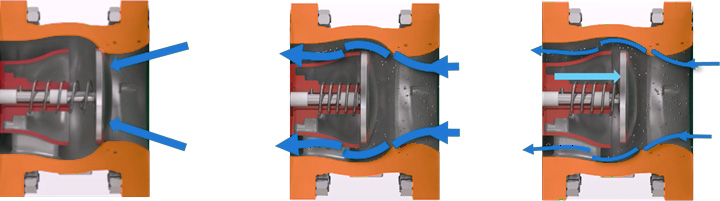

When the pressure differential between the upstream and downstream sides of the valve exceeds the cracking pressure of the spring, the obturator will move and allow flow. The flow area of the valve decreases steadily down to the seat diameter; this is the venturi design.

As a result of the venturi design, the reduced flow area increases the kinetic pressure and reduces the static pressure allowing the valve to fully open quickly. The spring is selected so that the disc is fully opened and stable against its backstop under normal flow conditions.

When a noticeable reduction in flow occurs, the spring reacts early against the force of the reducing flow.

Why is an Axial Flow Check Valve used?

When flow is reversed in a pipe, this can cause hydraulic shock waves to pass through (also known as water hammer). This can cause severe damage to equipment in the pipeline if measurements are not taken to prevent this. The introduction of the correct check valve, in a fully closed position during reverse flow can prevent this from occurring and causing severe issues at the site.

Valves that prevent water hammer and close rapidly without slamming are called non-slam check valves.

How are Axial Flow Check Valves used?

Axial check valves are specifically designed for fast-reversing systems where backflow is a constant concern. It is categorized as a non-slam check valve as the valve closes without slamming meaning no excess pressure spikes are created. Most axial flow check valves are spring-loaded, with a single low-mass disc, which facilitates fast, dynamic response to a reduction in flow. Due to having a single disc and spring when the disc is opening, the force is balanced resulting in an even flow.

Features of Axial Flow Check Valves

Axial flow check valves offer several advantages over other types of check valves, such as:

- Rapid closing action (prevents water hammering)

- The ability to be properly sized for each application

- Durability

- Increased valve longevity

- The ability to accommodate low-pressure drops and high flow

- Non-slamming opening and closing action

- Tight shut-off leading to zero leakage

- Various end-to-end options

- The ability to be installed in both horizontal and vertical orientation

Axial flow check valves offer many advantages over other types of check valves. Axial flow check valves can save time and money by preventing damage and increasing the lifetime of your pumps, valves, pipes, and other system parts.