Combination Air Valve

Description

Combination Air Valve

Festures of Combination Air Valve

- Suction at negative pressure;

- Fast exhaust;

- Exhaust only does not drain;

- Slight exhaust and large.

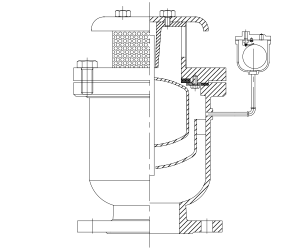

Combination Air Valve Working Principle

When tube began to water injection, the disc in the open position, a large number of exhaust, when the air line up, the full of water in the valve, floating ball up and drive the valve closed, stop the exhaust, when water tube is normal transportation, if there is a small amount of air within the valve to a degree, water levels fall in the valve, floating ball drops, the air is being exhausted from the holes. When the pump stops, the water flow in the pipe is empty or negative pressure is generated in the pipe. At this time, the plug is opened quickly and the air is inhaled to ensure the safety of the pipe.

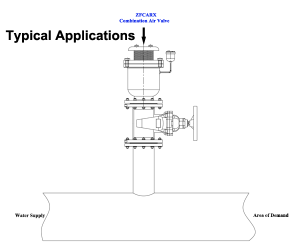

Combination Air Valve Installation and Commissioning

This valve is usually installed at the highest point of the system, such as tightening the bonnet on the valve body, the air valve stops the exhaust, normally, the bonnet should be open. Air valve can also be used with the block valve, convenient exhaust valve maintenance. For specific use, please consult ZECO Valve Group.

Combination Air Valve Material and Standard

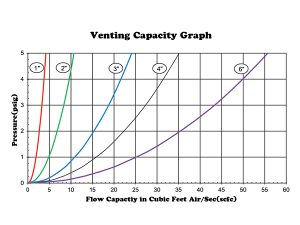

Size Range: 2″~8″

Pressure Rating: 10bar ~ 25bar

Face to Face Dimensions: AMSE B16.10, EN558-1

Flange End Dimension: AMSE B16.1/16.42, AS4087, EN1092-2

Coating: Fusion Bonded Epoxy Coating

Inspection and Test: ISO 5208 / EN 12226-2

| Part | Material | Standard |

| Body | Ductile Iron | EN 1563/DIN 1693 |

| Bonnet | Ductile Iron | EN 1563/DIN 1693 |

| Exhaust Hood | Ductile Iron | EN 1563/DIN 1693 |

| Float Ball | Stainless Steel 431 | EN10088-1/ASTM A959 |

| Strainer | Stainless Steel 431 | EN10088-1/ASTM A959 |

| Seal | EPDM / NBR | ISO 4633 |

| For the materials options not listed, consult factory.

ZECO manufactures valves in more than 50 different alloys. |

||