ZECO Valve is an API 6D approved professional check valve manufacturer,

What is a Check Valve?

Check valve is a type of forced backflow sealing valve, which can close the valve without leakage by applying pressure from the back medium. The media flow direction of the check valve can be from the front.

Check Valve Types

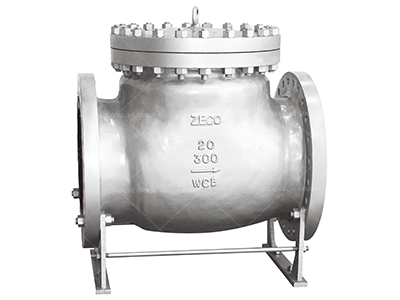

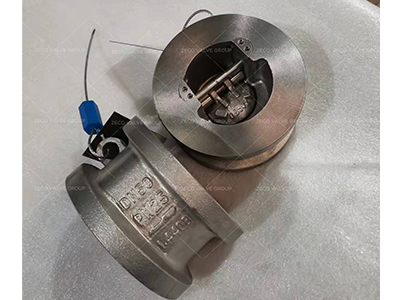

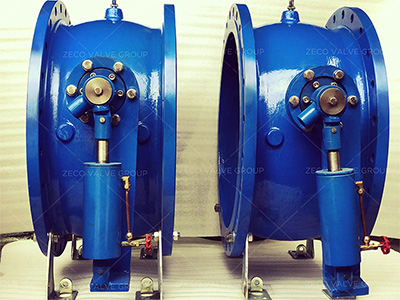

According to the movement mode of the disc, the check valve can be divided into the lifting check valve and swing check valve.

According to the connection mode, the check valve can be divided into a wafer check valve, flange check valve, and welded check valve.

How does a Check Valve work?

Check valve will usually indicate the direction of flow in the valve body, when the pressure of the imported medium is greater than the weight of the disc, the disc is pushed open by the medium, and the valve also opens. On the contrary, when the imported medium pressure is less than the weight of the disc, the disc is also closed, and the valve is also in the closed state. When combined with a globe valve, the check valve can play a role in safety isolation. The disadvantage is high resistance, and poor sealing when closing.

Competitive Check Valve Price

As a check valve manufacturer, We can effectively produce API 6D standards and control material and personnel costs to achieve competitive prices and reliable quality assurance to help give ZECO a definite competitive edge on the projects it is involved in.

Choose ZECO as Your Professional Check Valve Manufacturer

ZECO water & API 6D check valves are widely used in water & oil pipelines all over the world. In our case, they are used at the entrance of the hydropower station turbine, and they are installed at the water supply, oil pipe, line, and natural gas system. They are often used instead of cast and forged gate valves, carbon chvalvesalve, pressure seal check valves, and so on. Although the check valve can shut off the backflow medium, its flow resistance coefficient also has a very important effort on performance, because the return valve is different from the gate valve and butterfly valve so that the gate or disc is fully open without any flow resistance. The check valve needs the medium to flush the disc before flowing through the valve body. ZECO‘s check valve is its r & d team to travel around the world and well-known check valve manufacturers to communicate, under, and on this basis, own unique innovation and development. ZECO check valve has a very small resistance coefficient, automatic shut-down when backwater, and reliable performance, and why do we say that? As we have our own designed and developed valve testing system, we conduct performance and sealteststest for each newly developed and finished production valve to ensure that the check valve can be normally used under operating conditions and meet the final requirements of customers. The spring and disc of the feed check valve play an important role in the whole valve. Therefore, for each spring, we will use the fatigue testing machine and the elastic testing machine to ensure that the spring can maintain its normal state for a long time; For each disc, we will use precision equipment, such as numerical control equipment, and processing center. It is because of the previous process to the final inspection of the assurance that the check valve is safe.