What is a Cryogenic Valve?

Cryogenic Valves are the valves that could be used in low temperature condition, usually the valves will be treated as Cryogenic Valves when the working temperature will be lower than -40 Deg C.

Cryogenic Valves is often used in Oil Gas, Air Separation, Natural Gas industrial, etc, the quality determines that if it could work safety, economic, continuing. With the development of the modern technology, the Cryogenic Valves demands are more and more increased and the use ranges are widely enlarged.

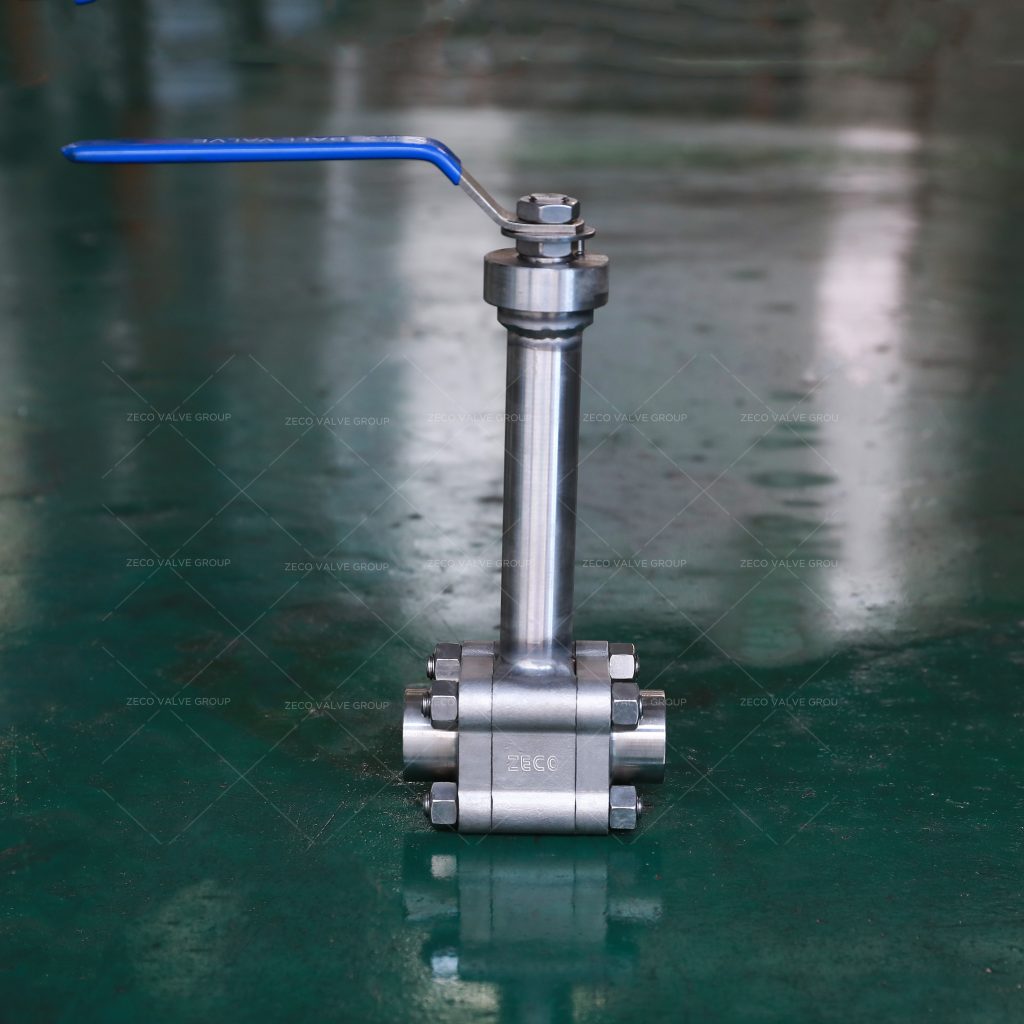

What is a Cryogenic Ball Valve?

Cryogenic Ball valves, as the name indicates, are ball valves that are used in extremely cold applications.

Long Neck Cover Design Used in Cryogenic Ball Valve

Valves suitable for medium temperatures ranging from – 40 C to – 196 C are called cryogenic valves, and these valves generally use long neck bonnet. Low-temperature valves specified by long neck cover include cryogenic emergency shutoff valves, cryogenic ball valve, cryogenic globe valves, cryogenic check valves, LNG special cryogenic valves, NG special cryogenic valves, etc. They are mainly used in 300,000 tons of ethylene, liquefied natural gas and other chemical devices. Output liquid cryogenic media, such as ethylene, liquid oxygen, liquid hydrogen, liquefied natural gas, liquefied petroleum products, etc., are not only flammable and explosive, but also gasifiable when they are heating up. When they are gasifying, the volume expands hundreds of times.

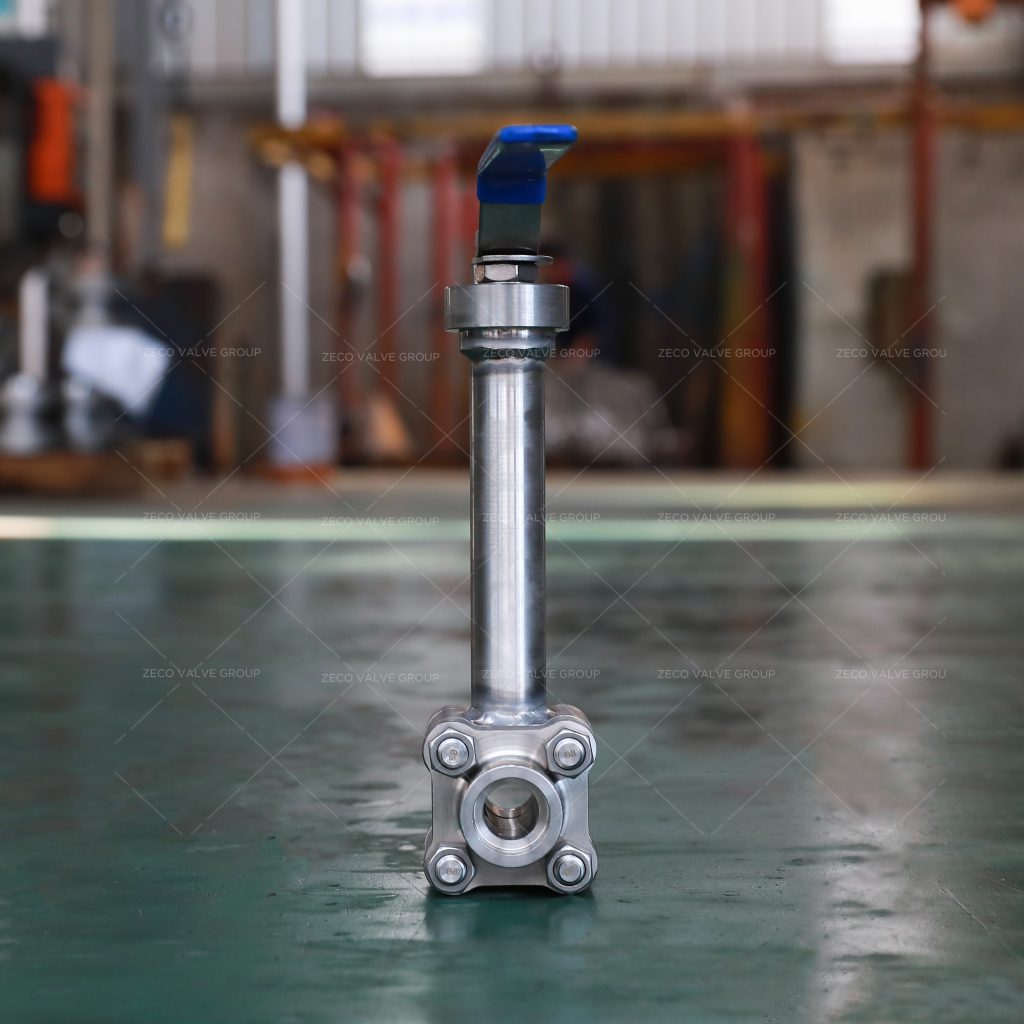

The Reasons Why Cryogenic Ball Valves Require Long Neck Bonnet

(1) The long neck cover has the function of protecting the packing box of the cryogenic valve, because the sealing of the packing box is one of the keys of the cryogenic valve. If the packing box leaks, it will reduce the cooling effect and lead to liquefied gas gasification. At low temperature, with the decrease of temperature, the elasticity of filler gradually disappears and the leak-proof performance decreases. As a result of medium leakage, the filler is caused and the valve stem freezes. It affects the normal operation of the valve stem and also causes serious leakage due to scratches of slurry filler caused by the movement of the valve stem up and down. Therefore, it is necessary to ensure that the temperature of the filler is above 8 C.

(2) The long neck valve cover structure is convenient for winding cold insulation material to prevent cold energy loss of cryogenic valves.

(3) The long neck structure of cryogenic valve is convenient for quick replacement of main parts of valve through the removal of valve cover. Because the process pipes and valves in the cold section of the equipment are often installed in the ”cold box”, the long neck valve cover can extend through the ”cold box” wall. When you are replacing the main parts of the valve, only the valve cover is needed to be removed, but the valve body is not needed to be removed. The valve body and pipeline are welded together to minimize the leakage of the cold box and ensure the sealing of the cryogenic ball valve.

ZECO Valve is one of the most professional cryogenic ball valve manufacturers.