API 600 Valve Trim Chart – ZECO Valve

What is API 600 Standard? API Standard 600, from the American Petroleum Institute, describes the criteria for valve design/construction and the material/trim … Read more

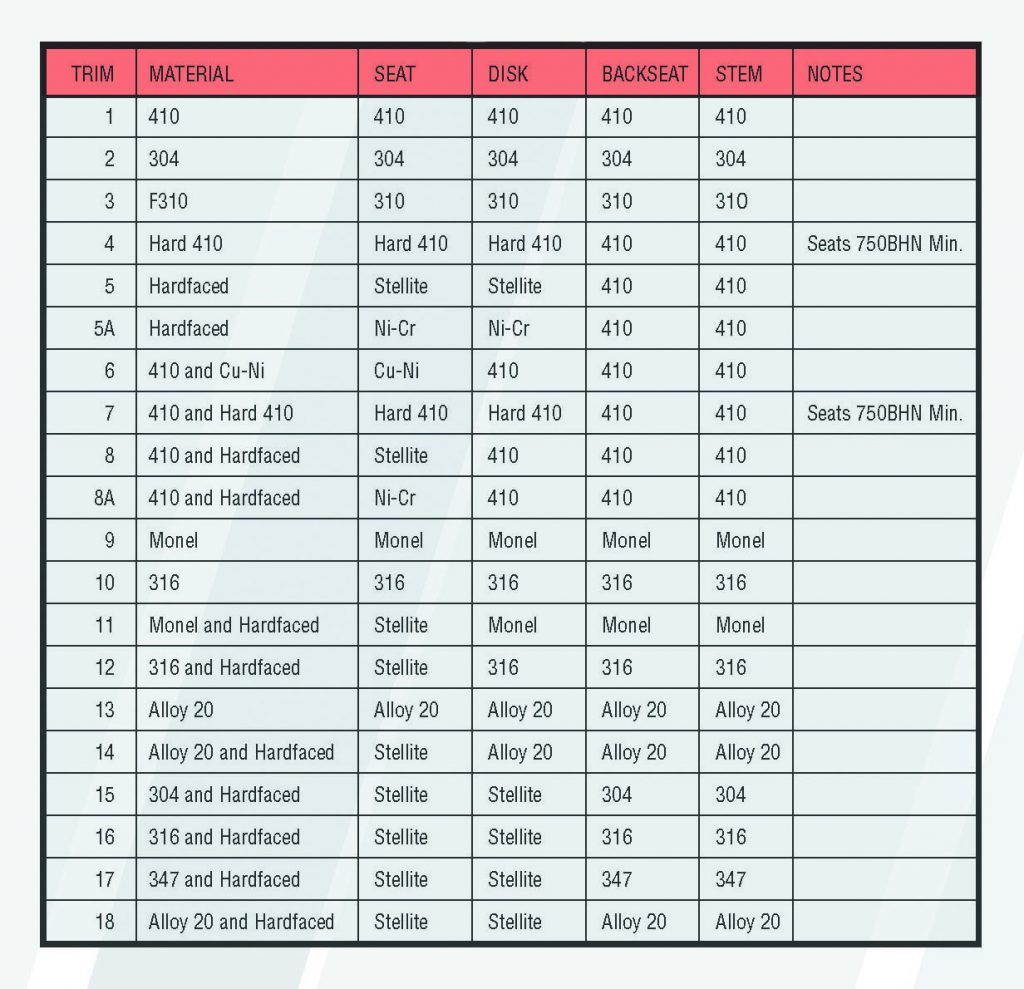

The removable and replaceable valve internal parts that come in contact with the flow medium are collectively termed Valve trim. These parts include valve seat(s), disc, glands, spacers, guides, bushings, and internal springs. The valve body, bonnet, packing, et cetera that also come in contact with the flow medium are not considered valve trim.

A Valve’s trim performance is determined by the disk and seat interface and the relation of the disk position to the seat. Because of the trim, basic motions and flow control are possible. In rotational motion trim designs, the disk slides closely past the seat to produce a change in flow opening. In linear motion trim designs, the disk lifts perpendicularly away from the seat so that an annular orifice appears.

Valve trim parts may be constructed of assorted materials because of the different properties needed to withstand different forces and conditions. Bushings and packing glands do not experience the same forces and conditions as the valve disc and seat(s).

Flow-medium properties, chemical composition, pressure, temperature, flow rate, velocity, and viscosity are some of the important considerations in selecting suitable trim materials. Trim materials may or may not be the same material as the valve body or bonnet.

| Trim | Material | Seat | Disk | Backseat | Stem | Notes |

|---|---|---|---|---|---|---|

| 1 | 410 | 410 | 410 | 410 | 410 | |

| 2 | 304 | 304 | 304 | 304 | 304 | |

| 3 | F310 | 310 | 310 | 310 | 310 | |

| 4 | Hard 410 | Hard 410 | Hard 410 | 410 | 410 | seats 750BHN Min. |

| 5 | Hardfaced | Stellite | Stellite | 410 | 410 | |

| 5A | Hardfaced | Ni-Cr | Ni-Cr | 410 | 410 | |

| 6 | 410 and Cu-Ni | Cu-Ni | 410 | 410 | 410 | |

| 7 | 410 and Hard 410 | Hard 410 | Hard 410 | 410 | 410 | seats 750BHN Min. |

| 8 | 410 and Hardfaced | Stellite | 410 | 410 | 410 | |

| 8A | 410 and Hardfaced | Ni-Cr | 410 | 410 | 410 | |

| 9 | Monel | Monel | Monel | Monel | Monel | |

| 10 | 316 | 316 | 316 | 316 | 316 | |

| 11 | Monel and Hardfaced | Stellite | Monel | Monel | Monel | |

| 12 | 316 and Hardfaced | Stellite | 316 | 316 | 316 | |

| 13 | Alloy 20 | Alloy 20 | Alloy 20 | Alloy 20 | Alloy 20 | |

| 14 | Alloy 20 and Hardfaced | Stellite | Alloy 20 | Alloy 20 | Alloy 20 | |

| 15 | 304 and Hardfaced | Stellite | Stellite | 304 | 304 | |

| 16 | 316 and Hardfaced | Stellite | Stellite | 316 | 316 | |

| 17 | 347 and Hardfaced | Stellite | Stellite | 347 | 347 | |

| 18 | Alloy 20 and Hardfaced | Stellite | Stellite | Alloy 20 | Alloy 20 |

Trim 10 is 316 stainless on both seat surfaces and 316 stem

Trim 12 is 316 stem, one seat surface 316, and one seat stellite #6 (hard faced)

Neither trim allows 304 stainless.

Typically people want the “upgrade” to trim 12 due to wear concerns and wanting to avoid galling by having dissimilar metals in seating contact. I would not assume somebody will accept trim 10 over trim 12.

Most likely a CF8 (304) valve will have API trim 2 (Not trim 10) which is 304 stainless on both seat surfaces and 304 stems.

API does not have a trim number for 304 with half satellite so often customers may say “trim 12” when what they really want is an all 304 stainless valve with one side hard-faced seat.

Valve trim levels range from AA through HH, and there are specific differences for each of these. Trim levels will determine the most suitable application for your needs and the required materials for the internal components of the valve.

The components affected by trim level changes include the:

AA is your general non-corrosive trim level. The material used in the AA trim level is 4130 for all components with the bonnet seal ring gasket being 1018.

BB is used in a general and slightly corrosive environment. The body and bonnet will be made from 4130, the gate and seat will be 410 Stainless Steel, it will have a 17-4 Stainless Steel Stem, and a 316 Stainless Steel bonnet seal ring gasket.

The CC valve trim type is used in a general, moderately corrosive environment with CO2. The body, bonnet, gate, and seats will all be 410 Stainless Steel. The stem will be made from 17-4 Stainless Steel, while the bonnet seal ring gasket will be 316 Stainless Steel.

DD-NL and DD-0.5 valve trim types are for sour, non-corrosive environments. All components in both trim levels are 4130 with the only difference being that DD-0.5 has a 17-4 Stainless Steel stem whereas the NL will most likely have a 4130 stem.

EE trim levels, like DD trim levels, are used in sour environments. EE-0.5 is used when the environment is slightly corrosive. EE-1.5 is used in highly corrosive environments with moderately abrasive CO2 present, and EE-NL is suitable when highly abrasive CO2 is present.

In all EE Trim levels, the body and bonnet are made from 4130 material. All gates, seats, and bonnet seal ring gaskets are Stainless Steel, with the gate and seats being 410 Stainless Steel and the bonnet seal ring gasket being 316 Stainless Steel. The difference in EE trim levels is the material used for the stems:

FF Trim levels are also used in a sour environment. FF-0.5 is for moderately corrosive environments with H2S. FF-1.5 and FF-NL are for highly corrosive environments with CO2 and H2S. The body, bonnet, gate, and seats are all made from 410 Stainless Steel, and the bonnet gasket is made of 316 Stainless Steel. The only part that is different between the three FF trim levels is the stem:

The last trim level is HH-NL, which is used in a highly corrosive and extreme service environment. The body and bonnet are both made from 4130 and have a 625 inlay throughout. The gate, seat, and stem are all made from 718 Inconel, and the bonnet seal ring gasket is 316 Stainless Steel.

What is API 600 Standard? API Standard 600, from the American Petroleum Institute, describes the criteria for valve design/construction and the material/trim … Read more

ZECO Valve is a proud industrial API 600 cast steel gate valve manufacturer. Our stainless steel gate valves, carbon steel gate valves, … Read more

Major valve parts include two types of functions one namely pressure-retaining which includes a valve body, bonnet or cover, Cover bolting, Disc, … Read more