Valve weld Skill improved: fish scale weld,TIG( Tungsten invert gas welding)

Welding Skill is very important for Some valve manufacture. ZECO’s pursuit of improving welding technology never stops. Last weekend, the ZECO welder … Read more

With slot welds, one surface is joined to another through an elongated hole. The difference between plug and slot welds is that the plug weld’s shape is characterized by its diameter, whereas the slot weld’s shape is characterized by both diameter and length. Depending on the part’s specifications, one end of the hole may be open, or the hole can be partially or completely filled with weld material.

Slot welds are beneficial when the part’s design requires an overlapping between two surfaces. Specific uses of slot welds include:

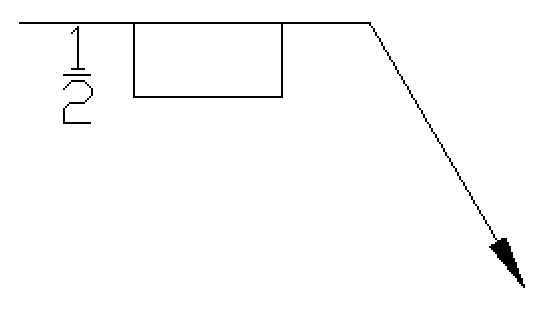

The slot weld symbol is the same that is used for plug welds. The symbol will not show a diameter symbol before the size however. The size of the weld will be the slot width instead. This is shown to the left of the symbol just as it is shown in plug welds.

The length of the slot weld will be presented to the right of the symbol. This may also include a pitch showing the center to center spacing of the slot welds. If there is a pitch there will be a number of slot welds provided in parenthesis under the symbol on the arrow side or above the symbol on an other side weld.

A slot weld can include any number of elements, these are very similar to the plug weld symbol that was just explained.

Welding Skill is very important for Some valve manufacture. ZECO’s pursuit of improving welding technology never stops. Last weekend, the ZECO welder … Read more