What is a Check Valve?

The valve that is used to prevent backflow in a piping system is known as a check valve. It is also known as a non-return valve or NRV. The pressure of the fluid passing through a pipeline opens the valve, while any reversal of flow will close the valve.

It allows full unobstructed flow and automatically shuts as pressure decreases. The exact operation will vary depending on the mechanism of the valve.

Types of Check Valve

- Swing Check Valves.

- Tilting Disk Check Valves.

- Wafer Check Valves.

- Spring Check Valves.

- Piston Check Valves.

- Ball Check Valves.

- Duo-Check Valves.

- Non-Slam Check Valves.

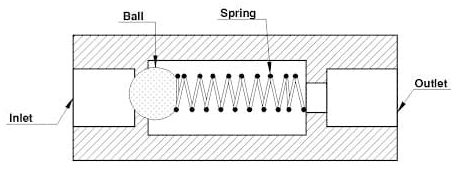

What is Spring Check Valve?

Spring Check Valve. Valves are versatile devices used for controlling the flow of liquids or gases. They play an important role in countless piping and process systems, typically serving to regulate flow and pressure, start or stop the flow, or prevent the occurrence of backflow within a system.

What is UPVC Spring Check Valve?

UPVC Spring Check Valve is suitable for plastic industrial applications; delivering excellent environmental and chemical resistance. A simple to install and maintain PVC valve, configurable as a Spring Check or Foot Valve offers a number of benefits where space and weight savings are not only required but play an important factor within the pipeline.

Key features of UPVC Spring Check Valve

- Available in Spring or Foot, connections: Imperial Solvent Socket, Metric Solvent Socket, and Screwed BSP.

- Sizes: 3/8″ to 4″ (Imperial Solvent Socket and Screwed BSP) and 16mm to 110mm (Metric Solvent Socket).

- Pressure rating: PN10/16 (Spring Check and Foot Valve).

- PVC-U body with EPDM ‘O’ rings.

- 100% factory tested.

PTFE Spring Check Valve Seat

PTFE Seats are manufactured using extrusion technology and can be cut and supplied in a wide range of standard sizes or can be supplied in custom-made shapes and colors.

Commonly PTFE Seats are used for fluid and gas transport seals, medical equipment, food and beverage equipment (e.g. coffee machines), and water delivery systems.

Standards of Check Valves

- Face to Face dimensions as ANSI B16.10

- End flange dimension as ANSI B16.5

- Pressure-temperature ratings as ANSI B16.34

- Pressure test as API 598

- Applicable Medium: water, gas, oil,and another causticity medium.

Spring Check Valve vs Swing Check Valve

The difference between swing check valves and spring check valves. The flapper in a swing check valve ‘swings’ off the seat to allow forward flow and then swings back onto the seat when the flow is stopped. In contrast, a spring-loaded check valve incorporates a spring to assist in closing the check valve.

Swing check valves are limited in the orientation in which they can be installed. Swing check valves can only be installed in horizontal flow applications, which greatly limits the installation orientation. While swing check valves do offer a larger flow capacity (larger CV value assuming the valve is fully open), they do not always fit in existing piping configurations. On the other hand, spring-loaded check valves can be mounted in any flow orientation with the right spring selections. So if you have a skid system, a difficult space with challenging dimensions, or even a unique direction of piping, choosing a spring check valve with the right spring setting (a.k.a spring cracking pressure) creates more possibilities for finding the right solution for your specific pumping system.

A spring-loaded check valve will help minimize the effects of the water hammer, while a swing check valve can exacerbate the issue. Any water hammering effects present in a piping system can potentially be amplified by a swing check valve. Let’s consider this basic example to explain the concept of a water hammer: say you have a line with water in it and you have a check valve. Downstream of that check valve, you have a quarter turn ball valve (this is one of the most commonly used types of control valves used for smaller line sizes). Let’s say water is flowing and someone shuts the quarter turn ball valve abruptly. This can produce a pressure wave flowing through the piping – this is what is known as a water hammer. With a swing check valve specifically, the flapper on that valve will be open until that pressure wave returns back to the swing check. The pressure wave causes the flapper to slam shut, which is very much audible and causes excessive wear within the swing check valve and other piping system components.

Conversely, a spring-loaded check valve will help minimize, and in some cases, eliminate the effects of a water hammer. How? When we think about that same pressure wave that closed the swing check valve, the spring in the spring check closes before the pressure wave gets there. Spring check valves are considered “silent check valves” by utilizing a spring to assist the poppet in closing the check valve prior to fluid flow reversal.

Applications of Check Valves

Valve is used for preventing the back-going of the medium in pipelines and equipment, and the pressure of the medium will bring the result of opening and closing automatically.

When the medium is back-going, the valve disc will automatically be closed to avoid accidents.

Related Tags :

Ten articles before and after