Double Orifice Air Release Valve

Description

Double Orifice Air Release Valve

Festures of Double Orifice Air Release Valve

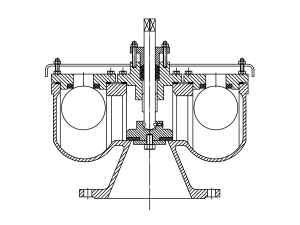

- Body is provided with a shock-proof inner tube to protect the float;

- Lower water pressure can be closed to prevent drainage;

- When there is negative pressure, the piston quickly opens to breathe;

- Stainless steel floating ball, long life.

Double Orifice Air Release Valve Working Principle

This valve exhaust, buoy, by gravity pull down one end of the lever, the lever in the tilt state at this moment, in the leverage and vent contact appeared gap, air through the vent through the gap, with the air discharge, water level rise, buoy under the effect of the buoyancy of water float upwards, the lever on the seal face pressure on the porosity, gradually until the vent is completely blocked. The exhaust valve is now completely closed.

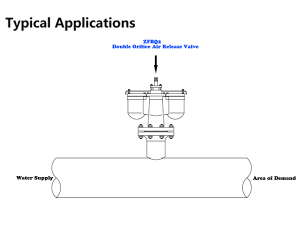

Double Orifice Air Release Valve Installation and Commissioning

When installing the double orifice air release valve, always install a protective valve on the front end to avoid stopping water from being tested. For specific use, please consult ZECO Valve Group.

Double Orifice Air Release Valve Material and Standard

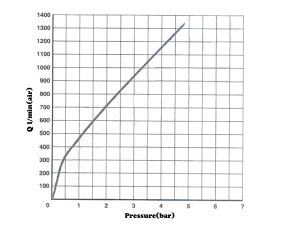

Size Range: 2″~12″

Pressure Rating: 10bar ~ 25bar

Face to Face Dimensions: AMSE B16.10, EN558-1

Flange End Dimension: AMSE B16.1/16.42, AS4087, EN1092-2

Coating: Fusion Bonded Epoxy Coating

Inspection and Test: ISO 5208 / EN 12226-2

| Part | Material | Standard |

| Body | Ductile Iron | EN 1563/DIN 1693 |

| Bonnet | Ductile Iron | EN 1563/DIN 1693 |

| Exhaust Hood | Ductile Iron | EN 1563/DIN 1693 |

| Float Ball | Stainless Steel 431 | EN10088-1/ASTM A959 |

| Strainer | Stainless Steel 431 | EN10088-1/ASTM A959 |

| Tank | EPDM / NBR | ISO 4633 |

| For the materials options not listed, consult factory.

ZECO manufactures valves in more than 50 different alloys. |

||