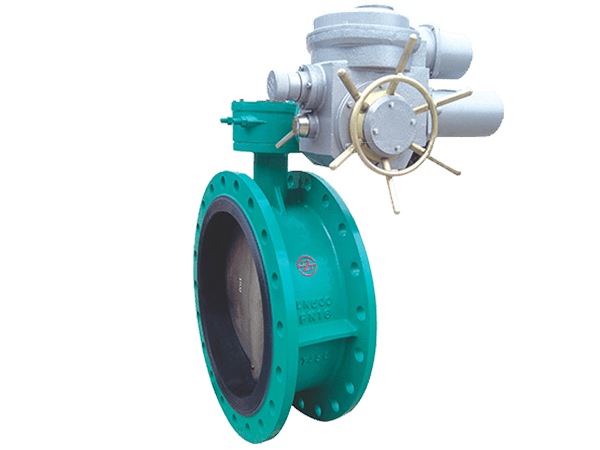

ZECO valve is exported to many countries; we have a British customer who once purchased a batch of Flange Butterfly Valves for their wastewater treatment plant with the following specifications:

| Pressure | PN16 |

| Body | Ductile iron |

| Disc | Ductile iron |

| Seat | EPDM |

| Stem | SS410/420/304/316 |

| Operation | Hand wheel |

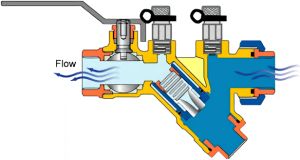

What is Flanged Valve?

A flange valve connection is a type of connection that uses a gasket between the flanges of a valve and pipe to seal the joint. It is secured with bolts, and if installed correctly, flange connections create a fluid-tight seal.

What is Flange Butterfly Valve?

A flange-type butterfly valve is one of the most frequently used valve types in industrial systems. It is small and light in weight and can be made into a large diameter. Compared with other valves, it has more space for use and is more cost-effective.

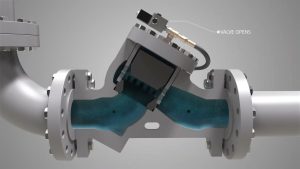

What is Double Flange Butterfly Valve?

Double flange butterfly valve used for regulation and flow sectioning in water supply facilities, plumbing, irrigation, etc. It has low head loss due to the hydrodynamic design of the disc; it is 100% watertight and needs no gaskets to be installed.

Our products are suitable for bulk solids, liquids, and slurries. They are robust in construction and available in several flange mounting types, materials, and actuator options.

ZECO valve factory can make targeted products according to the specific use situation and the user demand and guarantee the after-sales service.

BOM of Flanged Butterfly Valve

| Body & Disc Material | ASTM A 126 GR. B / IS 210 GR. FG 200/220/260 (Cast Iron) / Ductile Iron |

| ASTM A 216 GR. WCB (Cast Carbon Steel) | |

| ASTM A 351 GR. CF 8 / CF 8M (SS 304 / SS 316) | |

| ASTM A 351 GR. CF 3 / CF 3M (SS 304L / SS 316L) | |

| ASTM A 351 GR. CN7M (Alloy 20)/ ASTM A351 Gr. CF8C | |

| ASTM A351 Gr. CD4Mcu / ASTM A351 Gr. CK3MCuN | |

| ASTM A352 Gr. LCA / LCB / LCC (Low Temperature Carbon Steel) | |

| Aluminium Bronze / Hastelloy C – 22/276 / Super Duplex Steel | |

| NACE MR0175 / NACE MR | |

| Spindle/Stem Material | 304 / 316 (SS 304 / SS 316) – ASTM A 276 T |

| 304L / 316L (SS 304L / SS 316L) – ASTM A 276 T | |

| ASTM A 276 T – 410 (S.S. 410 – 13% Cr. Steel) | |

| Alloy 20 / Hastelloy / Monel | |

| Duplex Steel / Super Duplex Steel | |

| Seat (Bonded / Molded Type) | NBR, Buna-N, |

| Nitrile, EPDM, Neoprene, Hypalon, | |

| Silicon, Viton, |

Features of Butterfly Valve Flange

- Fully rubber-lined body, with lines extending up to the flange contact face to make gasket-free sealing.

- Ideal valve for installation with lined pipes since the disc chord interference with pipe ID is negligible.

- Controlled compression of the gasket face offers optimum sealing and prevents gasket face crushing.

- The unique triple sealing system for shaft sealing ensures zero secondary leakage.

- Self-lubricated PTFE lined bearings for both drive and non-drive end shafts ensure minimum bearing friction.

- Bi-directional tight shut-off sealing from vacuum to rated pressure.

- Excellent adaptability for actuated operation through standardized ISO top flange.

- Universal top square shaft enabling direct actuator fitment, after removal of a Hand lever, for sizes up to DN200.

- Choice of seat and disc materials to suit media and operating conditions.

- Enables installation close to other pipe fittings without disc interference.

- The preferred design for desalination plants, municipal water supply, and Effluent plants.

- Adjustable bottom thrust pad/bearing for DN250 and higher to handle axial thrust loading.

- DN600/DN650 size provided with “O Ring holder” type drive end shaft sealing arrangement for extra reliability.