What is a Pneumatic Ball Valve?

A pneumatic actuated ball valve uses compressed air to automate the control of media. Pneumatic actuated ball valves don’t rely on a motor, but they do require electricity when paired with an integral pilot or solenoid valve.

What is a ball valve pneumatic actuator?

Pneumatic actuator ball valves by the conversion of compressed air energy to mechanical motion. A rotary mechanical motion is required in a ball valve for a 90 degrees turn. Pneumatic actuator ball valves can be single-acting or double-acting.

Single-Acting Pneumatic Actuator

A single-acting pneumatic actuator uses a single compressed air input to turn the valve and a spring to return the valve to the normal position.

Double-Acting Pneumatic Actuator

A double-acting pneumatic actuator has two compressed air inputs to turn the valve and return the valve to the original position.

Ball Valve Pneumatic Actuator Types

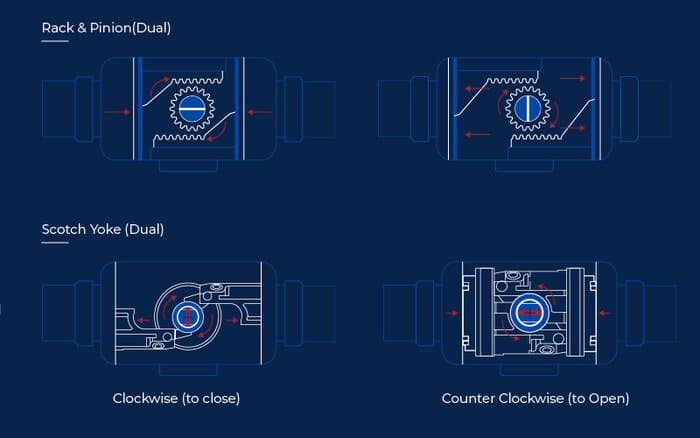

There are two main types of pneumatic actuators: scotch yoke and rack-n-pinion. While they both perform basically the same rotational operation on quarter turn ball valves, they do so using a different mechanical technique. Both types are available in spring return and double (direct) acting. Spring return pneumatic actuators will return to a “fail-safe position” upon loss of power or supply air. That position could be open or closed, whichever provides the best result for that system. Double acting pneumatic ball valves will simply remain in their current position when power or supply air is lost.

Rack and Pinion Pneumatic Actuator

Rack and pinion designs include a piston, rack and pinion. As air pressure increases on one side of the piston, it moves the rack inwards and through a gear connection with the pinion it spins the output rotary shaft. Rack and pinion actuators are found across the chemical, pharmaceutical, water processing and oil and gas industries.

Scotch Yoke Pneumatic Actuator

Scotch yoke designs feature a linear-moving piston connected to the rotary shaft by a pin and slot mechanism. As the air pressure increases and moves the piston linearly, it spins the rotary shaft through a cam system (pin and slot), Technology.org explains. “This will then in effect turn the valve and either open or close it.” Scotch yoke actuators are typically found in chemical and general process applications.

How does a pneumatic actuator work on a ball valve?

The most common mechanism for a pneumatic actuator for ball valves is the rack and pinion mechanism. This comprises of the rack (a linear gear) and the pinion (a circular gear). The rack is attached to a piston which is pushed by compressed air to achieve linear motion. This linear motion is converted to circular motion by the pinion. The pinion drives the stem of a ball valve to open and close positions.

To control the pneumatic actuator for ball valves, the compressed air is regulated by solenoid valves. Electrical signals from the controller energize the solenoid valve to either open or close positions allowing compressed air to flow through to both piston sides of the pneumatic actuator. The piston pushes the rack which turns the pinion connected to the stem of the ball valve.

Accessories that you can use with this Ball Valve:

- On/off Indicator

- Namur Standard Solenoid Valve in all Standard

- Pneumatic & Electro-Pneumatic Valve Positioner

- Declutchable Manual Override

- Limit Switches for On/Off Indication at Panel Board

- Filter + Regulator Combination with Pressure Gauge

- Air Lock Valve

How to choose ball valve pneumatic actuator?

Ball valve pneumatic actuator drive with all kinds of computer networking, alone or centralized control, Ball valve pneumatic actuator can use the analog or digital variables two kinds of signal control, supporting various kinds of modern control equipment, wild valve production, Ball valve pneumatic actuator is widely used in domestic petroleum, chemical, electric power, metallurgy, textile, food, medicine, environmental protection, urban construction and the research field,and exported to Europe, America, Middle East and southeast Asia market, well received by users.

Ball valve pneumatic actuator beautiful and exquisite shape, light weight, waterproof sealing structure. F4 guide rings are installed on moving parts of piston, rack and output shaft to achieve low friction, long life and avoid contact between metals. The installation connection size conforms to ISO5211, DIN3337 and VD1 / VDE3845 as well as NUMAR standards to ensure the interchangeability between ZE actuators and facilitate the installation of solenoid valves, limit switches and other accessories.

Model selection of ball valve double-acting pneumatic actuator:

Ball valve Double acting actuator is used to determine the torque of the valve first. Under normal service conditions, the recommended safety factor is 15 ~ 20%. The safety value is then added according to the fluid medium used by the valve. Increase the safety value of clean and lubricating media by 20%; Water vapor or non-lubricated liquid medium increases the safety value by 25%; Increase the safe value of 40% to the non-lubricated slurry liquid medium; Non-lubricated dry gas medium increases the safety value by 60%; Non – lubricated particulate medium increases the safety value by 80%. The safety value of non-lubricated particle powder medium transported by gas is increased by 100%; According to the torque value calculated above and the torque table of the double-acting actuator using air source pressure, the accurate ZE model can be obtained.

Model selection of ball valve single-acting pneumatic actuator:

Using the single-acting actuator, according to the torque value calculated above and the use of air source pressure, find the single-acting torque table, first check the spring reset end point, then check the end point of air source working pressure, the air source pressure torque should be greater than the spring reset torque, you can get the exact model. Note: In the ZE single gas-controlled output torque table, the “end” torque of the spring reset is the torque of closing the valve, and the “start” torque of the spring reset is the torque of opening the ball valve. The torque at the beginning of the corresponding air source pressure is the torque in closing the ball valve, and the torque at the end of the air source pressure is the torque in opening the ball valve.

Related Tags :

Ten articles before and after