Our ball valves adopt special parts different from those on the market, namely, balls with excellent materials and excellent performance, and each ball has passed the corresponding standard pressure test before assembly.

What is a Ball Valve?

Ball valves are quarter-turn on/off devices. A pivoting ball in the center of the valve controls the flow of liquid or gas media.

The pivoting ball is known as a rotary ball, and it is designed with a hole (a bore) in the center. A stem on the top of the ball rotates the ball to open or close the valve. The stem can be turned using manual levers or automation.

Ball Valve Types

Ball Valve For Sale List By Form

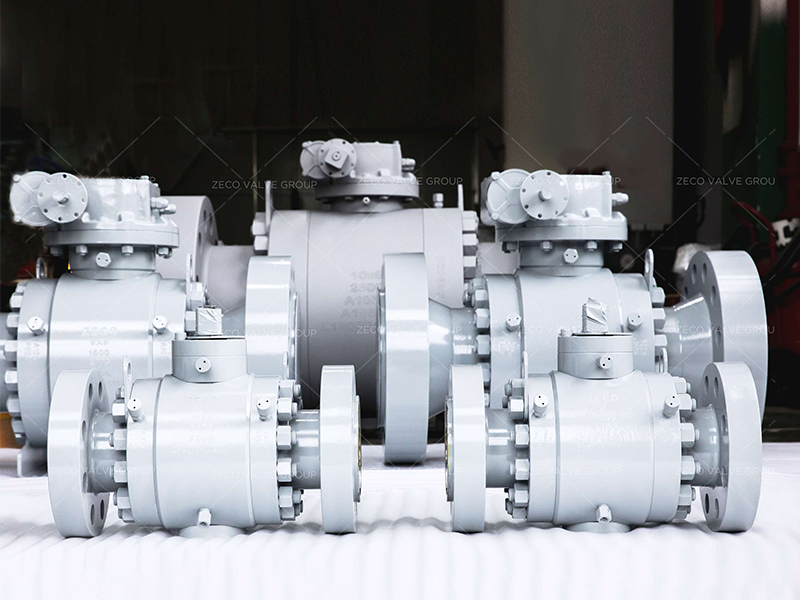

Zeco Valve produces trunnion ball valves and floating ball valves. The two major types of ball valves are specially designed for the corresponding operating conditions, covering almost all kinds of oil and natural gas operating conditions.

Driven by the stem, the ball valve revolves around its axis. According to the structural form, the ball valve can be divided into Floating ball valves, trunnion mounted ball valves, top entry ball valves, metal seated ball valves, full weld ball valves, and industrial ball valves.

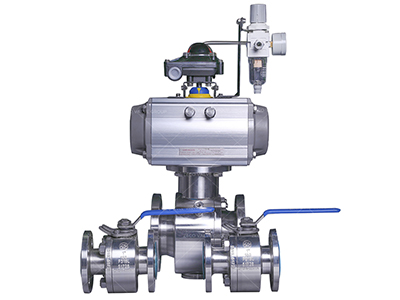

Ball Valve For Sale List By Drive Mode

The drive mode of the ball valve can be divided into manual, pneumatic, and electric, gear operated, and motorized. The quality of the ball valve is not only related to the quality of the product itself but also relevant to selecting the type correctly.

Ball Valve For Sale List By Material

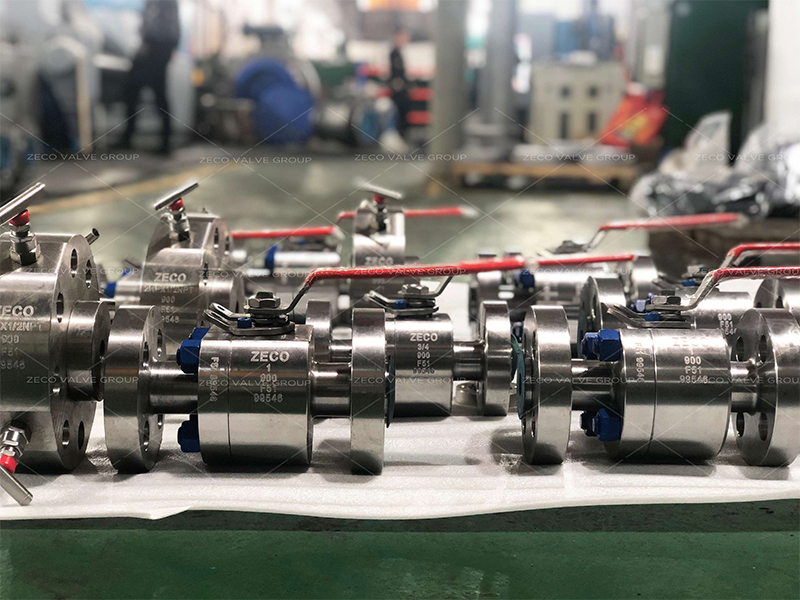

ZECO ball valves by material can be divided into cast steel and forged material ball valves.

When buying ball valves, it is significant to compare the different materials that are used to manufacture ball valves. The selection of the material used in the ball valve depends largely on the service condition of the valve. Body materials of ZECO ball valves include, but are not limited to stainless steel, wcb, carbon steel, forged, and cryogenic.

Ball Valve For Sale List By Size

The size of the pipe determines the size of the ball valve and the rate of flow required through the ball valve is considered first. ZECO international standard valve company manufactures the ball valve of smallest 1/2 inch, 3 inches, 4 inches, 6 inches, 8 inches, 12 inch, and maximum 56 inches.

Applications of Ball Valves

Ball valve products are widely used in petroleum refining, long pipeline, chemical industry, LNG, LPG, etc. ZECO ball valve features dual block and bleed capability, secondary sealant injection, and spring-loaded self-releasing seats, providing many beneficial features and options for oil, gas, and liquid applications.

The valve is used to cut off or switch on the medium within the pipeline and is widely used in petroleum refining, long-distance transportation pipeline, chemical, paper making, pharmaceutical, water conservancy, electric power, municipal and steel, etc.

Special consideration is made to the strength, safety, and resistance to the harsh environment during design. It’s suitable for various corrosive and non-corrosive mediums.

Different materials may be selected for transportation of water, steam, oil, natural gas, nitric acid, acetic acid, oxidant and urea. Ball valve has compact struck true and reliable sealing. Its sealing surface and spherical surface are closed normally which makes it resismakes to flush erosion by the medium, and easy to operate and repair. With the development of Zeco for decades, the performance and pressure strength of ball valves can be compared with the top products at home and abroad.

Choose ZECO as Your Professional Ball Valve Manufacturer

With the rapid development of research and development technology and material technology, ball valve has gradually become the main valve and gradually replaced the plug valve, and the operating temperature range has been the same as other types of valves, and compared with other types of valves have obvious advantages, its advantages reflected in the switch is simple and low torque, and minimum pressure drop-almost the same as the equivalent to the length of the pipe in the full bore valves-and equivalent to a reduction venture type in those of a reduced bore.

ZECO has nearly 30 years of experience in the field of ball valves in research and development, manufacture, and production of the metal seated ball valve. Sealing surface hardness and ball surface hardness, as well as the degree of the match after grinding, can achieve world-class standards. ZECO ball valves feature long life and safe operation in harsh environments. Maximum safety and environmental protection is the driving factor for each design. The ZECO valve is achieved through corrosion-resistant materials, fire safety testing, blowout preventer stem, and tight shutoff. From refrigerants to highly corrosive fluids, ZECO products are manufactured and tested according to the corresponding API, ASME, and ANSI standards.