Double Disc Globe Valve

Globe valve is truncated class, one of the most widely used in valves; valve widely used in various types and different parameters … Read more

GET GLOBE VALVE FLOW DIRECTION INFORMATION

Globe valves have become one of the most-used valves in companies in almost every industry. And with their ability to start, stop, and throttle fluid flow within a pipeline, it’s easy to see why.

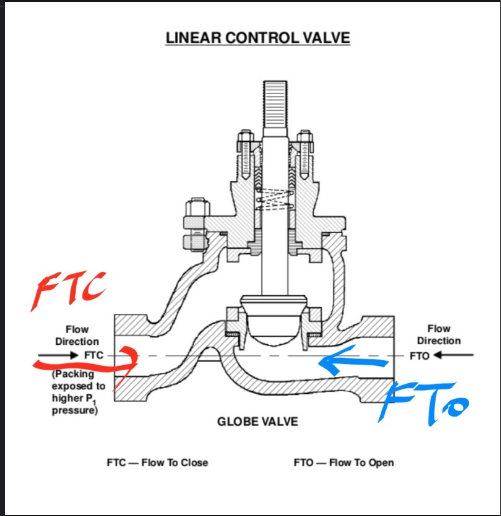

Generally speaking, the flow of globe vales is from down to up. It means the medium will go through from the disc downside and then out by the upside. Globe valves usually adopt a compulsory sealed design, so closing the valve offer pressure to the disc against the seat. So if you want to open the valve, the globe valve disc must overcome resistance made by stem and packing friction, medium pressure will offer adverse pressure which helps open the valve. It means you can use less force than the closing valve. So the stem diameter should be larger, to avoid stem bending fault. (depending on the metal material’s physical performance of the stem ). In recent years, there are more and more valve pressure seals, the medium through the upper disc to the down disc, so the close valve force is smaller than the open valve force, valve shaft diameter is allowed to be smaller.

But some opinions disagree with it, especially for a globe valve with a larger size (for example, a size bigger than DN250), the globe valve usually adopts a valve pressure seal, and considering closing valve force, it is easy to reach the seal performance. But it should take the stabilization of the valve into consideration when the valve stem diameter is smaller than the seat diameter.

But how exactly do these valves work and what’s the globe valve direction flow?

A globe valve is primarily designed to stop, start and regulate flow. It is comprised of a movable disk and a stationary ring seat in a generally spherical body. The seat of a globe valve is in the middle of and parallel to the pipe, and the opening in the seat is closed off with the disk. When the handle is turned, manually or through an actuator, a disc is lowered or raised by means of the valve stem. When the disc is fully lowered, the fluid flow is shut off. When the disc is fully raised, the fluid flow is at its maximum rate. When the disc is raised to the less than maximum level, the fluid flow is regulated in proportion to the vertical travel of the disc.

-For low-temperature applications, globe and angle valves are ordinarily installed so that pressure under the disk. This promotes easy operation, helps protect the packing, and eliminates a certain amount of erosive action to the seat and disk faces.

-For high-temperature steam service, globe valves are installed so that pressure is above the disk. Otherwise, the stem will contract upon cooling and tend to lift the disk off the seat ( and leak).

Also referred to as standard or forward flow, or in globe valves, flow under the seat. Think about when you’ve controlled the flow of water from a garden hose with your thumb. Your thumb acts like the face of the plug in a globe valve – flow is pushing against your thumb to open a flow path for the water.

Also referred to as reverse flow or in globe valves, flow over the seat. Consider a drain plug in a bathtub. The flow direction is against the back or top of the plug (rather than the face) creating a tendency for the plug to close into the drain.

Globe valve is truncated class, one of the most widely used in valves; valve widely used in various types and different parameters … Read more

Cast steel globe valve is one of the most widely used valves. The reason why it is popular is that the friction … Read more

Application scope of globe valve The opening or closing stroke of the stem of the globe valve is relatively short, which has … Read more

Globe valve, also called stop valve, is one of the most widely used valves. It is popular due to the small friction … Read more

Flow Characteristics of Globe Valve The opening and closing parts of the stop valve (globe valve) are plug-shaped discs, their sealing surface … Read more

1. Introduction of pneumatic globe valve Pneumatic cut-off valve, widely used in the important system of mine and nuclear power plant, is an … Read more

The function of power station probe valve: it is often used in water and steam pipelines as an on-off device. Installation regulations … Read more

What is a Stainless Steel Globe Valve? Stainless steel globe valve is a type of globe valve that is made of stainless … Read more