Installation of Pneumatic Ball Valve and Method of Prolonging Its Service Life

How is the pneumatic ball valve installed? Can the pneumatic ball valve be installed vertically? The pneumatic ball valve can be installed … Read more

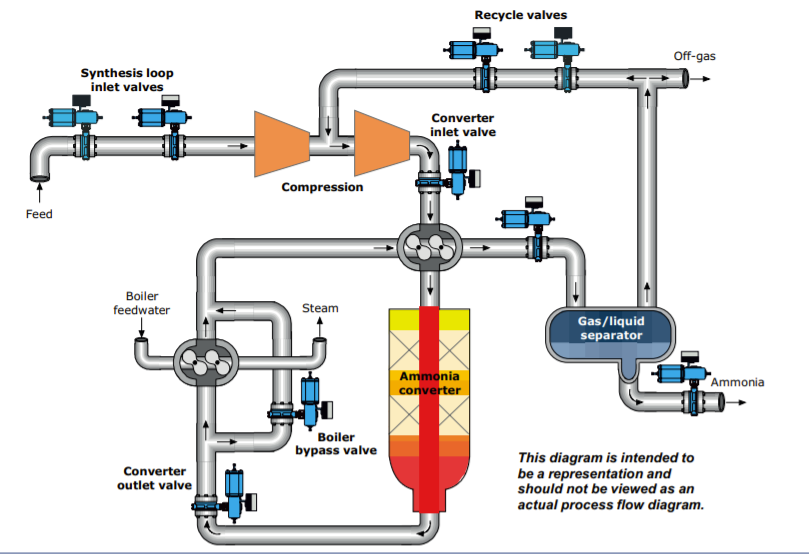

Ammonia synthesis is used to produce ammonia from nitrogen and hydrogen. The produced ammonia can then be used as a fertilizer, or it can be further processed into urea or nitric acid. A mixture of hydrogen and nitrogen, usually originating from a steam reformer, is admitted to the synthesis loop and then compressed in two stages into the synthesis pressure of 150-300 bar (2200-4400 psi). The stream is preheated by heat exchange with the hot effluent coming out of the converter before entering the ammonia converter.

The ammonia conversion process is a compromise between temperature and pressure. For the catalyst to be efficient a temperature of at least 400 °C (750 °F) is needed,

but since the reaction is exothermic a higher temperature negatively affects product yield. To counter this issue, the pressure is increased to push the reaction equilibrium toward ammonia (thus increasing product yield). Heat is recovered from the effluent by generating steam and by pre-heating the incoming feed. The effluent is then sent to refrigeration before the product is separated from the medium and unreacted gas is recycled to the start of the synthesis loop.

The role of valves in the ammonia synthesis loop is to control the flow of synthesis gas into the converter and to ensure the recycling of the unreacted synthesis gas.

This valve is used to adjust the flow of synthesis gas into the converter. The flow may need to be adjusted to cope with temperature fluctuations in the converter.

This valve is located after the reactor and is used to regulate the flow of effluent to the boiler.

This valve is used to control the flow of reactor effluent that bypasses the boiler, allowing the amount of pre-heating by the synthesis gas heat exchanger to be controlled.

Ammonia is a colorless gas that consists of nitrogen and hydrogen (NH3). At atmospheric conditions, it is lighter than air with a pungent odor. It is a highly caustic irritant that is both toxic and flammable. Because of its low boiling point, as a liquid, it must be stored under pressure or at a low temperature. Industrial ammonia is sold either as ammonia liquor or as pressurized or refrigerated anhydrous liquid ammonia transported in tank cars or cylinders. Household ammonia or ammonium hydroxide is a solution of NH3 in water. Most ammonia is consumed in the manufacturing of fertilizer. It is also a building block for the synthesis of many pharmaceutical products and is used in many commercial cleaning products.

Ammonia valves are engineered for performance and reliability in the most hazardous industrial processes such as severe ammonia applications. These valves are available in a “floating” type with two basic body configurations – split body in full and standard port and a unibody in standard port only.

All components used for ammonia service, in a gaseous or liquid state, are specifically cleaned to remove any traces of oil, grease, or hydrocarbon materials prior to the valve assembly. Valves for ammonia service are assembled in an oil-free restricted area by personnel who are specially equipped and trained to perform this task. The assembling area, work, surfaces, equipment, and tools are specially maintained to ensure cleanliness requirements are met.

How is the pneumatic ball valve installed? Can the pneumatic ball valve be installed vertically? The pneumatic ball valve can be installed … Read more

Electric ball valve is an important actuator in industrial automation control system. It rotates around the valve stem in line with the … Read more

Application scope of globe valve The opening or closing stroke of the stem of the globe valve is relatively short, which has … Read more