To understand the “T”-port “L”-port, 3 way valves, and what makes them different, it’s important to first establish what each of these terms means. By clearly defining each term, the difference in directional flow purpose will be easier to understand. First, let’s define exactly what a diverter valve does.

What is a 3 Way Ball Valve?

Three way ball valves are the most popular and economical type of multi-port valves. This style of valve is commonly used in applications with more than one source of media or to divert media in two different directions.

Depending on the flow direction, the three ports are assigned as either one outlet and two inlets, or one inlet and two outlets.

A 3-way ball valve provides the ability to:

- Mix two different types of media (Selector Valve)

- Divert the flow of media (Diverter Valve)

What Types of 3 Way Ball Valves Are There?

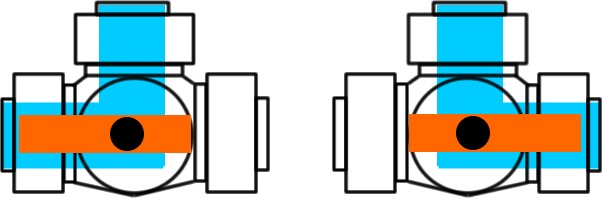

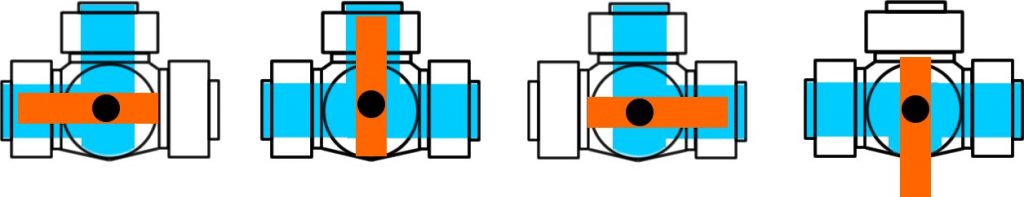

There are two types of 3-way ball valves: L-Port and T-Port. An L-Port can send flow one way or the other or can shut it off completely. A T-Port will perform all the same flow tasks as an L-Port but cannot be shut off. In addition, the T-Port can mix flows by sending or receiving flow to/from both ways of the Tee. The “T” and “L” refer to the shape of the opening in the ball.

How a 3 Way Ball Valve Works?

A 3-way ball valve works by turning the handle, which rotates a ball in the valve body, to align the cut-out channels in the ball with the inlets and outlets of the valve. The “L” shape cut-out of the ball on an L-port valve sends fluid through 90 degrees from one port to another. The “T” shape cut-out of the ball on a T-port valve can also send from one port to another, but can also be rotated so that the T aligns with the “T” shape of the valve and all three ports are mixed.

Difference between 3 Way Ball Valve and 2 Way Ball Valve

In simple comparison, a 3 way ball valve has one more port than a 2 way ball valve. But why? A two way ball valve allows fluid to enter the valve from one port, and exit through the other. Having a third port allows fluid an alternate path of travel, either when exiting or entering the valve. This permits fluid to either exit from more than one point, or enter the valve from more than one point.

What is a 3 Way Ball Valve T Port?

T-ports and L-ports, while similar, do different things. To accomplish this, the bore of the valve‘s ball is drilled in a particular shape. A “T” shape allows one action, while an “L” facilitates another. Both shapes provide options for diverting fluid flow from or to different sources, but each design offers unique functions. In the case of a ball drilled with a bore in the shape of a “T,” fluid can be directed to more than one location simultaneously: when the ball is in the open position, fluid is allowed to pass through the valve at full pressure to point “A” while allowing fluid to travel to point “B” at a slightly lower pressure. In this way, a T-port 3-way valve is designed for directing fluid to multiple destinations.

What is 3 Way L Port Ball Valve?

An L-port valve, on the other hand, performs the opposite function and directs fluid from multiple sources. For example, the use of an L-ported valve facilitates the ability to draw fluid from more than one source. A simple turn of the handle changes the position of the ball inside the valve and allows a change in the drawing source. So, when one tank is empty, fluid can be drawn from the next.

Diagram showing L Port Ball Valve Vs T Port Ball Valve:

What is the Used of T Port Ball Valves and L Port Ball Valves?

The L Port Ball valve is commonly used to direct the flow from two separate sources in one direction. For example – When emptying tanks, once one tank is empty the fluid can be drawn from the next tank to the same line by turning the handle to change the source.

The T Port Ball Valve is commonly used for directing the flow in two directions. Fluid is directed to more than one location simultaneously, passing directly through the valve body as well as to the side port at a slightly lower pressure.

Related Tags :

Ten articles before and after

The invention of dual plate check valve – Zeco |API Approved Valve Supplier

Basic and important steps of valve maintenance – Zeco |API Approved Valve Supplier

Why use extended bonnet for cryogenic valves? – Zeco |API Approved Valve Supplier

The structure of a nozzle check valve – Zeco |API Approved Valve Supplier

What is a gate valve and how does it work? – Zeco |API Approved Valve Supplier

A brief introduction of global industrial valves – Zeco |API Approved Valve Supplier

Are all globe valves designed to lower to upper? – Zeco |API Approved Valve Supplier

Valve’s Forming Process Technology: Casting & Forging – Zeco |API Approved Valve Supplier

Different media temperature for different body/ bonnet – Zeco |API Approved Valve Supplier

Banquet for Mid-Autumn Day – Zeco |API Approved Valve Supplier