What is a High Performance Butterfly Valve?

High Performance Butterfly Valves use a disc offset from the seat center, hence the name Double Offset Butterfly Valve.

In this configuration, the disc is eccentric, or offset, from the valve seat. As the disc starts to rotate, it moves away from the seat instead of across it. This design actually uses the line pressure to help give it its seal. This feature allows the use of offset butterfly valves in high-pressure applications such as ethanol or HVAC. It generally uses PTFE or plastic as its seat material, but metal seats are also available to meet fire-testing specifications like API 607.

How does a High Performance Butterfly Valve work?

This valve operates using a handwheel/hand lever or actuator. A handwheel or hand lever is used in manual valves and it is where the operator applies force to start and stop the valve. The actuator is used in automatic valves to provide the torque needed to start and stop the valve. To open a high-performance butterfly valve, the stem is rotated for 90o degrees in the anticlockwise direction by the torque applied by the actuator or on the handwheel as necessary. At the same time, the disc rotates at the same 90o degree angle. This rotation forces the disc to align itself parallel to the fluid flow where it leaves an unobstructed path. To close the valve, the stem and disc are turned in the opposite direction (clockwise) for a 90o degrees angle only. This aligns the disc perpendicular to the flow path and then it stops any fluid crossing through the high-performance butterfly valve. These valves are also used in throttling applications in which the valve disc is rotated slightly to allow some amount of fluid to flow. High-performance butterfly valve manufacturers recommend the use of these valves in throttling applications if only there is a low-pressure drop.

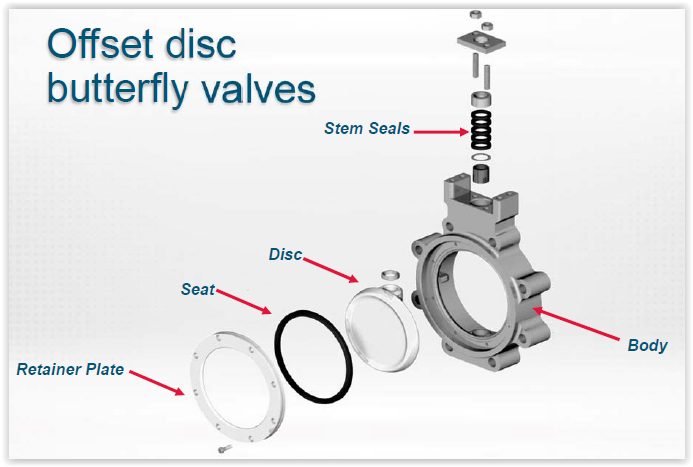

Components of a High Performance Butterfly Valve

- Stem: The high-strength, one-piece stem is 17-4 PH Stainless Steel. The valve stem is standardized for the interchangeability of international actuators.

- Blow-out Proof Stem: A retaining ring is installed between the machined stem groove and gland retainer step.

- Adjustable Stem Packing: The stem packing system features easy access to adjusting hex head nuts without requiring the removal of the actuator. The system consists of a gland ring, a gland retainer, studs, hex head nuts, and lock washers. A 1/4 turn of the hex head nuts is usually all that is required should field adjustment ever be needed. Both hex head nuts must be evenly adjusted and not overtightened.

- Stem Seal: The stem seal system provides constant compression for a positive seal around the stem. PTFE packing seals the stem and a carbon fiber anti-extrusion ring contains the packing. Flexible graphite rings are available for high-temperature applications and are standard on fire-safe valves

- Stem Bearings: Top and bottom bearings, consisting of a 316 Stainless Steel shell with a TFE/glass fabric liner bearing surface securely supporting the stem. The stem bearings provide excellent resistance to corrosion and distortion from high temperatures and mechanical loading forces

- Taper Pins: Taper pins are precision fit into reamed holes.

- Disc: The disc has been engineered to maximize flow and minimize resistance providing a high Cv. Stainless Steel is standard.

- Internal Travel Stop: Designed to prevent travel of the disc and minimize possible seat damage, therefore extending the service life of the seat.

- Seat: Zeco offers a wide variety of seat options including a PTFE seat, reinforced PTFE seat, flexible metal seat, and a dual seat.

- Full-faced Seat Retainer: The retainer is firmly attached by bolts located outside of the sealing area, protecting the bolts from corrosion.

- Body: All body styles offer bi-directional sealing as standard to full ASME Class 150, 300, or 600 ratings. The extended neck allows for 2″ of pipeline insulation and easy access to stem packing adjustments and actuator mounting.

Applications of High Performance Butterfly Valves

High Performance Butterfly Valves are specially designed for applications in the chemical, hydrocarbon processing, pulp & paper, water & wastewater, and HVAC industries worldwide.

They have been successfully applied in extreme services, including high-temperature services, throttling steam control, polymerizing media, liquor service with entrained solids, high cycle industrial gas, process gas-off applications, paper stock isolation, vacuum pump isolation, corrosive chemical service (titanium construction), fire-safe refinery & chemical service, heat transfer service, and throttling hydrocarbon service.

Advantages of High Performance Butterfly Valves

- Reduced fugitive emissions through triple-leak protection of primary stem seal plus two optional secondary seals

- Increased capacity and improved flow control with low-profile, double-offset disc

- Improved personnel and plant safety per adherence to API 609 criteria for safe, reliable anti-blowout protection

Disadvantages of High Performance Butterfly Valves

- These valves are expensive compared to other butterfly valves.

- These valves open while the valve disc is in the fluid flow path which reduces fluid flow pressure.

- High-performance butterfly valves are suitable for throttling use only where fluid pressure drop is low.

- The sealing of these valves is poor compared to that of other valves like ball valves.

ZECO Valve is one of the Chinese largest and most respected manufacturers of high quality HIGH-PERFORMANCE BUTTERFLY VALVE. From Design, Engineering, Manufacturing, QC, and After-sales services, ZECO Valve provides a Total Solution to our customers helping to give them a competitive advantage in the marketplace.

Butterfly valves use a round disc controlled by a control lever or wheel to completely shutoff a pipe. When the lever is moved a quarter turn, the disc stands upright and perpendicular to the flow of fluids, closing the valve and blocking any liquid or gas from flowing down the pipe.

Leading High Performance Butterfly Valves Manufacturers

Butterfly Valves & Controls, Inc.

Butterfly Valves & Controls, Inc. has been a premier supplier of quality butterfly control valves and other related industrial components for 25 years. We carry only the best parts sourced from world-class butterfly valve manufacturers. Extended service life and safe operation are at the core of every valve manufactured/assembled. Our catalog includes a large selection of valves, actuators, controls, positioners, and more.

Emerson Electric Co.

Butterfly valves and other industrial valves and equipment have been manufactured by Emerson for more than 130 years. The corporation has established itself as the world’s leading maker and supplier of control valves, not just in America.

Emerson is well-known for being the finest. Their products are widely utilized in oil and gas facilities, as well as in virtually every other industry. Emerson’s proven track record of manufacturing valves with high accuracy and high-quality processes has made them stand out for years. They also have their own cryogenic testing laboratory where they test all of their valves using helium.

Flowserve

Butterfly valves, as well as seals, actuation, pumps, and instrumentation systems, are all available from Flowserve. Flowserve provides services to customers in the oil and gas, chemical, power, water, and general industrial sectors. The firm provides fluid motion and control services in 56 countries.

Crane

Crane Co. has over 165 years of expertise in the valve sector and is well acknowledged as a pioneer. The corporation is based in Stamford, Connecticut, in the United States. Butterfly valves are among the company’s top-of-the-line designed industrial products and solutions. Aerospace, hydrocarbon processing, electronics, chemical, petrochemical, power generation, automated commerce, transportation, and other sectors all employ their goods. North America, South America, Europe, Asia, and Australia are all served by Crane.

Related Tags :

Ten articles before and after

Typical Applications Of Butterfly Valves

Double Offset Butterfly Valve-Best Butterfly Valve In The Industrial World

What Is A High Performance Butterfly Valve

What Is The Characters Of A Double Offset Butterfly Valve

Zeco Creative Design For High Performance Butterfly Valve Stem Bearing

Pressure Swing Adsorption (PSA) Technology

Supper Size High Performance Butterfly Valve Is Ready For Shiping From Zeco VALVE