Actaris Metering Systems offer regulators for residential, commercial and industrial use. The Actaris Gas Regulator Technology portfolio serves all market segments. It meets almost any recognized standard and can be customized to individual specifications. All products of Actaris Metering Systems are available at Zeco Valve.

Actaris Gas is a major business line of the Actaris Group, an established global leader in metering products and systems for distributing gas, electricity, water and heat.

Actaris has over 100 years of proven experience in the manufacture and use of Gas Pressure Regulators and associated safety devices. Our Total Quality policy ensures that today’s technically advanced product ranges comply with the highest national and international standards, to meet the exact needs of different gas distribution systems in North America and Europe.

Our Gas Pressure Regulators are designed for accurate, dependable and safe use with most non-corrosive gases including air, nitrogen, dry carbon dioxide, and propane, in natural gas distribution systems and industrial applications such as burners and boilers.

An extensive range of regulators is manufactured to US standards in Owenton, Kentucky. This line is designed with a building block approach, utilising common components and parts throughout the product range. The result is an extremely versatile and innovative product range that offers an economical solution to the most challenging regulator applications.

The European product line, manufactured in Karlsruhe, Germany covers most applications in natural gas distribution, from high pressure regulators used in city gate stations to residential regulators. These regulators and safety devices offer a wide range of combinations, including integral safety shut-off valves and built-in creep relief valves.

A Unique Safety Feature: the Internal Monitor

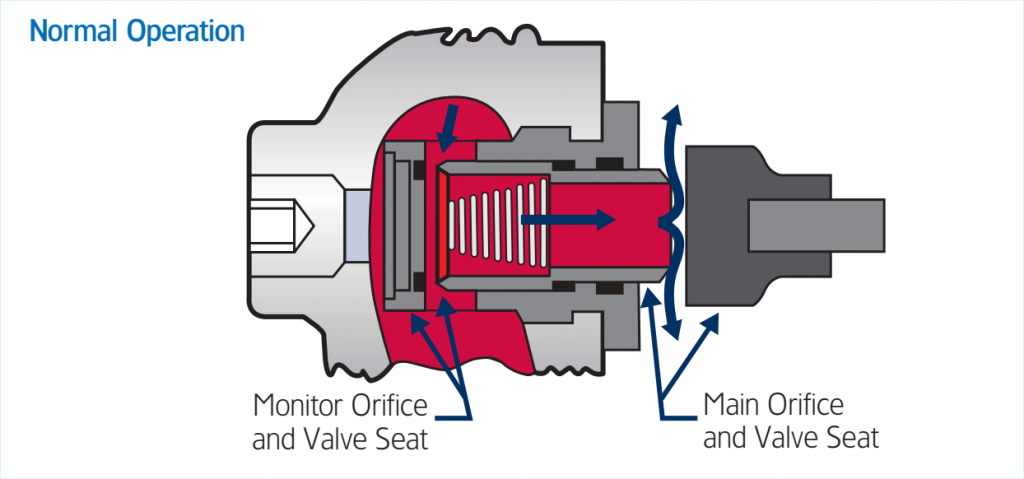

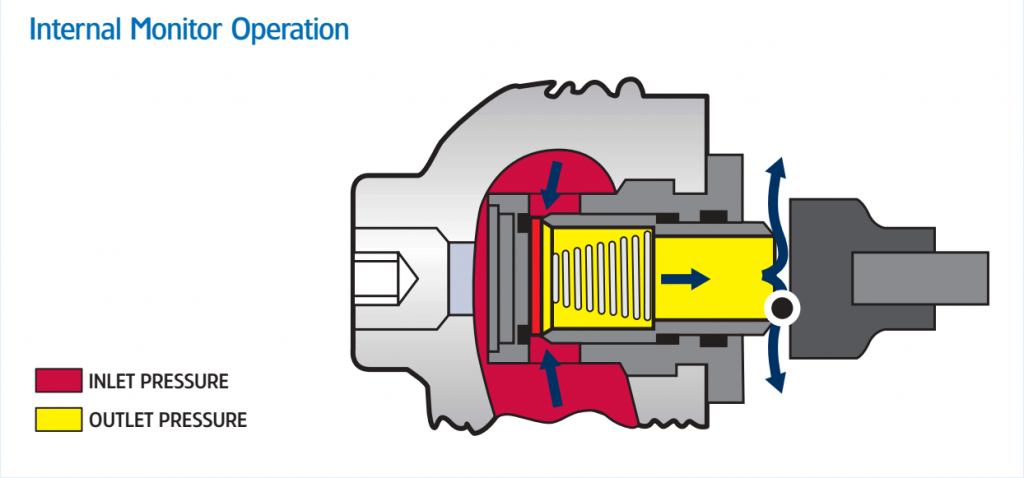

A unique safety feature available exclusively in Actaris regulators is the Internal Monitor (IM). A secondary orifice and valve seat enable an IM regulator to control the flow of gas and to lockup in the event of a failure at the main seat and orifice. The IM prevents the venting of large amounts of gas into the atmosphere and does not require manual resetting. For added safety and overpressure protection, the IM is a cost-effective alternative to installing monitor regulators or external relief valves.

The internal monitor (IM) operates like a standard upstream monitor set, in that the monitor orifice is wide open under normal conditions. Normal regulation and lockup occur at the main valve seat and orifice. (The closing spring causes CL models to lock up at both seats under normal conditions.)

If the regulator fails to control the flow of gas due to foreign matter or damage at the main seat and orifice, the secondary orifice automatically takes control at a slightly elevated outlet pressure. The point of regulation moves to the upstream monitor seat and orifice.

Low Pressure Regulators

Actaris low pressure regulators are designed for residential customers or small collective distributors wherever the network pressure is slightly higher than the typical 19 to 22 mbar, including urban centre networks and old renovated networks. They function perfectly with very little pressure loss and are designed to be mounted directly onto users’ meters or at the foot of their residential buildings.

These regulators meet all security requirements for use inside residential buildings. When necessary, they are equipped with a security device to protect against excess flow – usually with automatic reset. This interrupts the gas flow if there is abnormally high demand, in the case of rupture of a conduit downstream to the regulator, for example, or an abnormal drop in inlet pressure in the distribution network.

Spring Loaded Service Regulators

Actaris Spring Loaded Service Regulators are used primarily for final stage lower outlet pressure applications (20 mbar to 150 or 350 mbar – Inches W.C. to 2 or 5 psig). Typical applications include residential and low outlet pressure commercial and industrial gas supply, and all types of gas-fired equipment including furnaces, boilers, dryers, ovens, heaters etc. Spring loaded regulators provide extremely fast response to changing downstream flow conditions.

Unique features of Actaris spring loaded service regulators include:

Controlled Boost

All regulators are equipped with boosting devices (B42: raised lip on valve seat, all others: adjustable loading ring) to offset pressure droop at high flows caused by spring and diaphragm effect.

Controlled Breather Opening

All regulators are equipped with a soft seat vent valve to ensure proper breathing and stability under all conditions.

High Capacity Internal Relief

All spring loaded regulators are equipped with internal relief as standard, relief flow paths are as large as practical to provide the least resistance to venting gas in the event of an over pressure situation, thus minimizing pressure build-up.

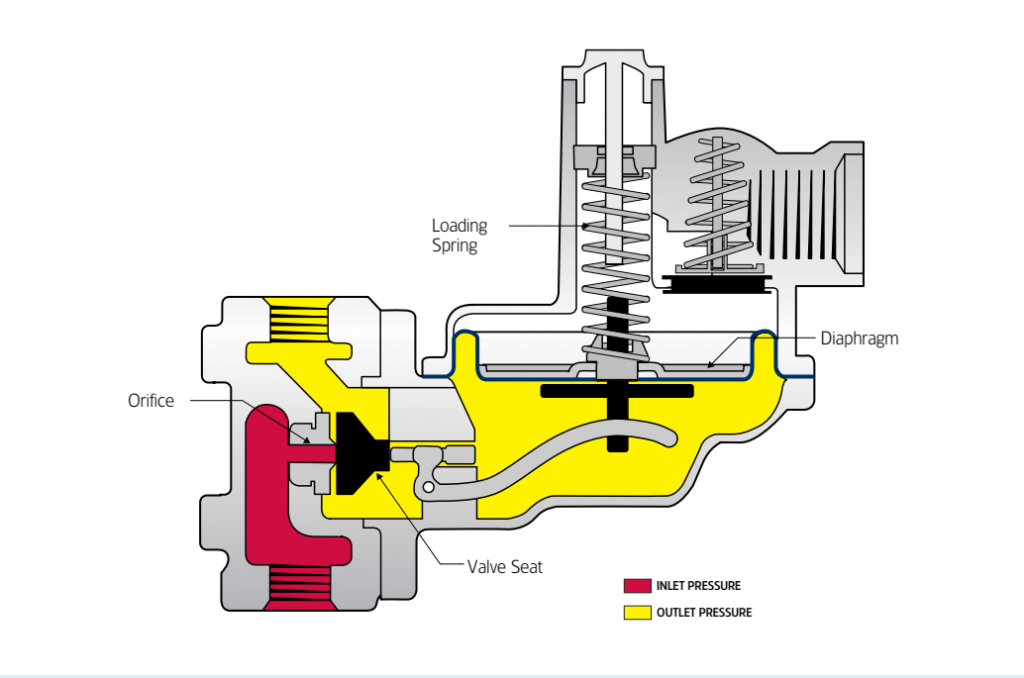

Spring Loaded Regulators: Principle of Operation

Inlet pressure is reduced to a lower outlet pressure by restricting flow through an orifice to match a fluctuating downstream demand.

As downstream demand increases, outlet pressure drops slightly, and the diaphragm moves downward. The valve seat moves farther away from the orifice face to allow flow to increase to match the increased demand.

As downstream demand decreases, outlet pressure increases slightly, moving the diaphragm upward. The valve seat moves closer to the orifice face to restrict flow to match the decreased demand.

When demand is shut off, outlet pressure continues to rise, moving the diaphragm up farther. The valve seat is driven into the orifice face, shutting off the flow of gas bubble-tight (lockup).

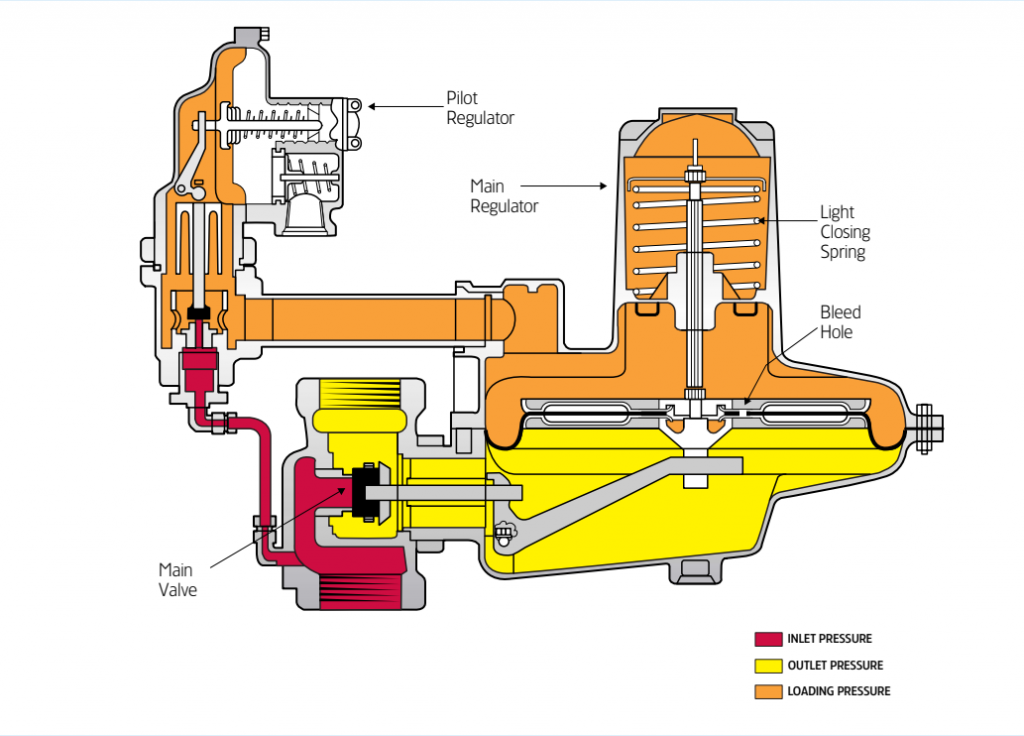

Constant Loaded Regulators

These regulators use constant pressure supplied by a pilot regulator as the loading element for the main regulator. This design eliminates the outlet pressure droop at high flows associated with the spring effect in spring loaded regulators. CL regulators can thus maintain extremely accurate regulation at higher flows and higher outlet pressures than spring loaded regulators. Typical applications include elevated pressure gas system to commercial and industrial installations, fixed factor metering installations (eliminating the need for expensive instrumentation), and all types of applications requiring accurate “psi-to-psi” regulation at widely varying flow rates.

Features of Actaris constant loaded regulators include:

Accurate Regulation

Constant loading pressure is supplied to the main regulator by a pilot regulator enabling “straight-line” regulation to be maintained over a wide range of flows and outlet pressures

Internal Bleed

Loading pressure bleeds downstream through the main diaphragm. No bleed occurs at lockup.

Low Pressure Differential

CL regulators can operate with as little as 30 mbar differential between inlet and outlet pressure.

Constant Loaded Regulators: Principle of Operation

Inlet pressure is piped through external tubing to the piliot regulator. The pilot regulator is adjusted to reduce the inlet pressure to the desired outlet pressure plus enough pressure to overcome the light closing spring (loading pressure). Constant loading pressure is piped to the top of the main regulator diaphragm.

When demand is approximately some hundred dm3/h or less, gas is supplied through a bleed hole in the main diaphragm.

When demand increases above what can be supplied through the bleed hole, outlet pressure decreases slightly, causing an increase in pressure differential across the diaphragm. The diaphragm moves downward, and the main valve is repositioned to match the increased downstream demand and recover desired outlet pressure.

When flow decreases, outlet pressure increases slightly, causing a decrease in pressure differential across the diaphragm. The closing spring causes the diaphragm to move upward. The main valve is repositioned to restrict flow to match the decreased downstream demand and recover desired outlet pressure.

When demand is shut off, outlet pressure continues to rise. The increased pressure is transmitted through the bleed hole to the pilot regulator. The pilot regulator locks up bubble-tight. The closing spring maintains bubble-tight lockup at the main valve.

Twin Parallel Flow Regulators

These regulators incorporate two diaphragm actuators and a single valve body into a self-contained regulator. Parallel regulation through dual orifices allows increased capacities. Twin relief valves (spring loaded models) provide double relief capacity. The use of two smaller orifices in place of one large orifice improves lockup, inlet effect performance, and relief performance.

The Internal Monitor versions of the twin regulators provide the highest level of safety available in a single regulating device. Twin sliding orifices provide normal dual regulation, with secondary monitor regulation and lockup in the event of multiple internal seat failures and/or a single diaphragm or lever failure.

Field Service Regulators

These regulators are designed to provide dependable first and second stage regulation for intermediate and high pressure applications. Typical applications include first stage regulation, farm & suburban taps, compressed air systems and medium to high pressure industrial applications.

Residential Regulators

Actaris 2R Series

Actaris B31 regulator

Actaris B42 regulator

Actaris B57 regulator

Actaris B58 regulator

Actaris HR91

Actaris KEMus

Actaris SERUs

Actaris WMR / EN

Commercial and Industrial Regulators

Actaris 133 and 233 Controller

Actaris B34 regulator

Actaris B38 regulator

Actaris B838 Controller

Actaris CL231 controller

Actaris CL31 Controller

Actaris CL34 Controller

Actaris CL38 Controller

Actaris CL838 controller

Actaris RB 1700/1800

Actaris RB 2000

Actaris RB 3200

Actaris RB 4000

Actaris RB 4600

Actaris RB 4700

Actaris RR 16

Field Service Controls

Actaris B35 regulator

Actaris B36 regulator

Actaris B56 regulator

Actaris VR75

Safety Devices

Actaris SRV 155

Actaris SRV 275

Actaris SRV 285

Actaris SRV 801/811

Actaris SRV 803

Actaris SSV 8200 and 8300

Actaris SSV 8500

Actaris SSV 8600

Related Tags :

Ten articles before and after

McDonnell & Miller WFE Uni Mach Electronic Feeder – Zeco Valve

Hydramotor Actuator H10 / H25 – Zeco Valve

McDonnell & Miller Series AF1, AF2, AF3 Air Flow Switches – Zeco Valve

Actaris Gas Meters and Modules – Zeco Valve

Belpa 3 phase transformers – Zeco Valve

ITT General Controls Various Models – Zeco Valve

Oertli Oil and Gas Burners – Zeco Valve

McDonnell & Miller Series 150S/157S Low Water Cut Off/Pump Controler – Zeco Valve