Y strainers filter out solids by using a perforated or wire mesh strainer. They are most frequently used in pressurized lines for gas, steam, or liquid. While it is most common to see Y strainers installed horizontally, they can be installed vertically as well. Ensuring proper vertical installation of Y strainers involves understanding where in the pipeline the strainer should be placed, making sure there’s room for screen removal during clean outs, and, most importantly, aligning the arrow on the strainer with the pipeline flow.

Introduction to Strainer in Piping

Strainer can be defined as a pipe fitting through which liquid is passed for purification, filtering or separation from solid matter; anything used to strain a liquid; any device functioning as a sieve or filter used to prevent solid bodies from mixing in a liquid stream or flowline.

Strainers arrest pipeline debris such as scale, rust, jointing compound and weld metal in pipelines, protecting equipment and processes from their harmful effects, thus reducing downtime and maintenance. Use of rightly selected strainers at correct locations (usually upstream) is a must to protect expensive and critical downstream equipment such as pumps, flow meters, steam traps, control valves etc.

Strainers can be classified into two main types according to their body configuration;

- Y Strainer

- T-Type or Basket Type Strainer

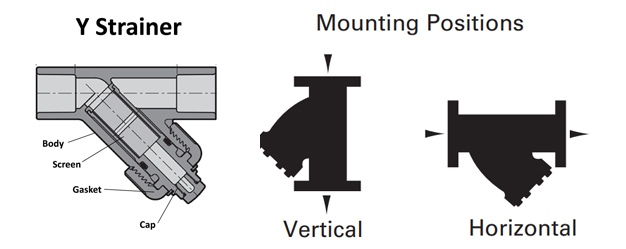

Orientation of Y-Type Strainer

A Y-strainer can be installed in either a horizontal or vertical position (Downward flow) with the screen element pointing downward. This allows the strainer screen to collect material in the strainer at the lowest point of the screen.

In horizontal steam or gas piping, Y type strainer should be installed in such a manner so that the pocket is in the horizontal plane. This stops water from collecting in the pocket which can cause erosion and affect heat transfer processes.

In liquid systems, the pocket should point vertically downwards. This ensures that the removed debris is not drawn back into the upstream pipework during low flow conditions.

Steps for Installing Your Y Strainer in a Vertical Position

Installing a Y strainer (such as one of these) is not difficult, but you will need to make sure everything is aligned properly and facing the right direction.

- Step 1: Install the blowdown valve (if necessary) at the blow-off connection.

- Step 2: To ensure maximum efficiency, install a pressure gauge at the inlet and outlet.

- Step 3: The Y strainer needs to be positioned in the pipeline ahead of any equipment that requires protection. For example, if it is the pump that is requiring protection, the Y strainer should be placed on the suction side of the pump.

- Step 4: Before you put the Y strainer in place, support the existing pipeline with pipe supports near the inlet and outlet connection.

- Step 5: The wye side of the strainer must be pointed downward. Ensure there is ample space at the wye side of the strainer for screen removal.

- Step 6: Place the Y strainer into the pipeline, ensuring that the flow arrow on the body of the Y strainer is pointing in the direction of the pipeline flow.

Installation orientation of the strainer must also be considered. If a vertical installation is planned, a Y-Strainer is the one that will work. Y-Strainers can be installed either vertically or horizontally. A basket strainer must be installed horizontally.

Whether you choose a wye or basket strainer, a spare basket or screen should always be purchased at the same time. A spare screen or basket makes clean-out easier. Just remove the dirty one and install the clean spare one. The line is back in service quicker and the dirty screen can be cleaned or replaced later.

And remember, nothing is quite as useless as a strainer without a basket or screen. If the basket breaks or gets lost or damaged, the line is out of service until a new one is located, purchased and installed. Having a spare on hand avoids this downtime problem.

How to Select a Strainer

Basket strainers and Y-Strainers each have design parameters that will affect their success in specific applications. Taking a little time to identify application specifics will ensure that you select a strainer that will perform as expected in your piping system.

The first thing to determine is the flow rate. Any flow rate over 150 GPM will most likely require a basket strainer because of pressure drop considerations. Strainers are usually sized so that their start up pressure drop is no greater than 2 PSI, with a line velocity not to exceed 8 FPS. On a per size basis, basket strainers exhibit less pressure loss than Y-Strainers. On this website, under Product Downloads, there is a Pressure Loss Calculator.

The next application parameter is difficult to determine, but is important. You need to know just how dirty the process media gets. Y-Strainer screens are smaller in dirt holding capacity than the strainer baskets used in basket strainers. So, in a given application, a basket strainer will go longer between cleanings than a Y-Strainer will.

This is also important because cleaning the screen of a Y-Strainer can be a messy affair compared to a basket strainer. Remember: the strainer leg of the Y-Strainer must be below the pipeline, pointing down, to trap the debris. This means that when the cap is removed to clean the screen of the Y-Strainer, be prepared for any fluid trapped in the strainer to drain out immediately. Depending on the process media, and the location of the strainer, this can be a significant problem.

This problem doesn’t exist with a basket strainer. The hand removable cover of a basket strainer is on top. After making sure there is no line pressure, just screw off the cover and lift out the basket to clean or replace it.

Metal Y-Strainers sometimes have a blow-down connection on the cap to permit cleaning the screen without removing the cap. This is not recommended with a plastic Y-Strainer because the hole in the cap would weaken the strainer and affect its pressure rating.

So, if the application requires infrequent cleaning and the process media is environmentally safe, a Y-Strainer should work. If the opposite is true and the strainer will be cleaned often and the fluid is less than friendly, a basket strainer is the answer. If in doubt, select the basket strainer every time. It may cost a bit more but will stay in service longer between cleanouts, and it will be easier to clean.

If the application requires that the system has to run continuously and cannot be shut down, then the only real choice is a duplex basket strainer.

Size of the perforations in the screen or basket is another consideration. Hayward plastic Y-Strainer screens are only available in 1/32″ perforation. Basket strainers, depending on size, come with 1/32″, 1/16″, 1/8″ or 3/16″ perforation plastic baskets. Stainless steel baskets and screens are available with perforations from 40 microns up to 1/2″, for both basket and Y-Strainers.

Related Tags :

Ten articles before and after

What are Plastic Valves and Their Advantages – Zeco Valve Company | Professional valve manufacturer

Bronze Valve VS Brass Valve – Zeco Valve Company | Professional valve manufacturer

Diaphragm Valves Types – Zeco Valve Company | Professional valve manufacturer

What are lined Valves – Zeco Valve Company | Professional valve manufacturer

What is Double Block and Bleed Valves ? – Zeco Valve Company | Professional valve manufacturer

What is a control valve – Zeco Valve Company | Professional valve manufacturer

HOW DOES A KNIFE GATE VALVE WORK – Zeco Valve Company | Professional valve manufacturer

GATE VALVES VS KNIFE GATE VALVES – Zeco Valve Company | Professional valve manufacturer

Stellite 6 Coating for Valves – Zeco Valve Company | Professional valve manufacturer