What is a Bellows Valve?

A Bellows Valve is a specially designed valve suitable for use in industries dealing with a hazardous medium where even minute leakages can be extremely critical. With the exponential growth of new industries such as the chemical and nuclear industry, there is a growing abundance of flammable, hazardous, extremely poisonous, and toxic media flowing through the pipelines. This creates a high risk of leakage, explosion, and health hazards. So, the valves used in such pipes and systems have specific stringent leakage and sealing requirements.

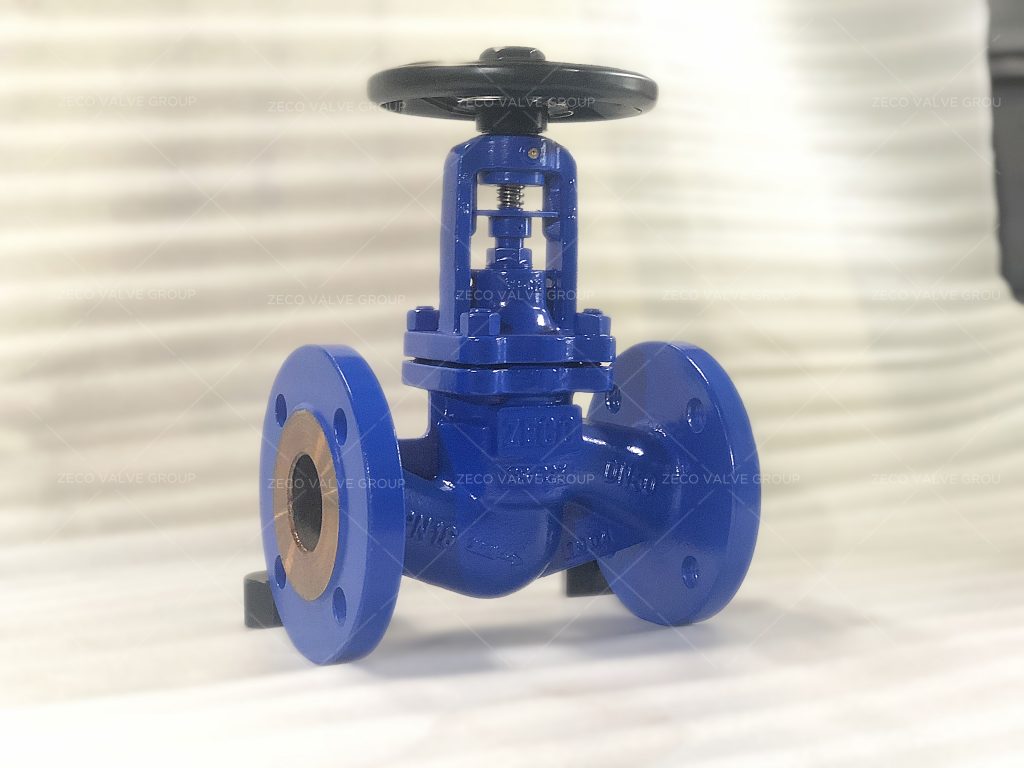

The need for a completely different approach required for the desired sealing & redundancy has led to the development of Bellow seal globe Valve.

How does Bellow Seal Globe Valve work?

A Bellow Seal Globe Valve is a compact structure that is a kind of control valve which uses bellows for sealing the valve stem components. The bellows valve has a bellow inside, and the lower end of the stainless-steel bellows is welded to the stem to prevent the system fluid from eroding the stem. The other end is positioned between the body of the valve and the cover of the valve to create a permanent seal. This double seal configuration eliminates leakage i.e., even if the bellows collapses, the stem packaging will prevent further leakage. The bellows are welded to the valve stem to ensure stable operating efficiency and prevent the vibration of the valve stem induced by the movement of the valve insert.

Comparison Between Bellow Seal Globe Valves with Traditional Valves

| Bellow Seal Valves | Piston Valves | Conventional Valves | |

|---|---|---|---|

| Primary stem seal | Metallic Bellow | Piston Ring | Gland Packing |

| Secondary stem seal | Gland packing | None | None |

| Stem Leakage | Not Possible since Metallic Bellows are designed to last several thousands cycles | Occurs as soon as the ring wear out. | Very common. Due to friction between stem occurs within a few cycle no matter which make valve or quality of gland packing |

| Packing Replacement | Not applicable | Rings need to be changed frequently | Packing needs to be replaced very often |

| Replacement Cost | Not applicable | Very High | High |

| Media Loss | Zero Loss. As the isolation is by metallic bellows, leakage (in ppm) is not possible. | Large in case of leaks | Considerable amount through gland leakages. Normally large amount when leakage remains unattended. |

| Equipment Downtime | Nil | Very High for replacing rings | Very high for replacing gland packing |

| Maintanance Cost often | Nil | High as rings need to be changed atleaset once in six months | Very high, Gland packing needs to be replaced / repacked. The cost along with equipment down tme, man hours spent act is very high. |

| Valve Life | High-in years | Low | Very Low – in -months. Due to leakage through gland, certain parts erode, making the valve irreparable after some months. |

| Safety | Can be used safely for almost any media | Can be used for limited medi like steam, hot water | Highly unsafe when the media is hazardous / poisonous |

| Cost | Comparatively higher initially but lowest total cost of ownership | High compared to the benefits | Initially low but very high after some years if cost pf packing, down time, man-hours spent, number of valves replaced act. are taken in to account. |

Advantages of Bellow Seal Globe Valve

- Double seal design (bellows + packing) If bellows fail, stem packing will also be avoided.

- Reasonable structure, reliable sealing, excellent performance, beautiful appearance.

- No fluid loss, reduce energy loss, improve plant equipment safety.

- The sealing surface surfacing Co based hard alloy, wear resistance, corrosion resistance, friction resistance, long service life, reduce the number of maintenance, reduce operating costs.

- Rugged bellows seal design ensures zero stem leakage and no maintenance.

- Stop valve stem conditioning and surface nitriding treatment, has good corrosion resistance and friction resistance;

- More intuitive indication of valve stem lifting position.

Applications of Bellow Seal Globe Valve

Bellows seal globe valve is suitable for petroleum, chemical, pharmaceutical, chemical fertilizer, electric power and other industries under various working conditions of the pipeline, used to cut off or put through the pipeline medium.

Related Tags :

Ten articles before and after

News – Comparison of pneumatic control valve and hydraulic valve | Professional valve manufacturer

News – Cryogenic valves for LNG applications | Professional valve manufacturer

News – Welcome to the new website of Zeco VALVE | Professional valve manufacturer

News – Types and selection of pneumatic valve accessories | Professional valve manufacturer

News – Top Ten Chinese Valve Manufacturers | Professional valve manufacturer

News – forged steel valves and cast steel valves | Professional valve manufacturer

News – Top 10 China ball valve manufacturer list in 2020 | Professional valve manufacturer

News – China Gate Valve product market analysis | Professional valve manufacturer