Pressure relieving devices include mechanisms such as Pressure Safety Valves (PSV) and Pressure Relief Valves (PRV), although there are other types of pressure relieving devices as well, such as Rupture Disk Devices and Pin-Actuated Devices.

What is a PSV Valve?

PSV – Pressure Safety Valves are usually used as a final safety solution when all previous systems fail to prevent any further pressure accumulation and protect vessels from rupture due to overpressure by their designed action. Armatec supplies both pilot operated safety valves as well as spring actuated with or without supplementary loading system. The latter can guarantee better tightness up to set pressure allowing higher operating pressures of the plant.

Types of PSV

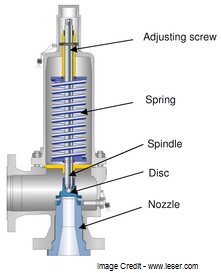

Spring-operated conventional safety valve

In a Spring loaded Pressure Safety Valve the closing force or spring force is applied by a helical spring which is compressed by an adjusting screw. The spring force is transferred via the spindle onto the disc. The disc seals against the nozzle as long as the spring force is larger than the force created by the pressure at the inlet of the valve.

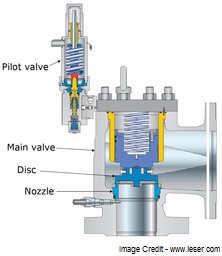

Pilot operated (Disturbed) safety valve.

Pilot Operated Safety Valve is controlled by process medium. To achieve this, the system pressure is applied to the pilot valve (= control component for the main valve) via the pressure pickup. The pilot valve then uses the dome above the main valve piston to control the opening and closing of the main valve.

What Factors Should I Consider When Selecting a Pressure Safety Valve?

Because Pressure Safety Valve play such a vital role in the protection of equipment and the safety of personnel, it is imperative to select the best valve for your application. There are several factors that need to be considered before purchasing:

- Set Pressure- You will need to determine the set pressure, which is the pressure point at which your pressure safety valve will need to open.

- Temperature- The temperature affects the volume of the process medium and also determines the what material is required for the valve components.

- Back pressure- The amount of back pressure will determine which type pf pressure safety valve you need.

- Application- Your application and the type of process medium that you are working with (steam, gas, liquid) will also play a factor is selecting a valve with the correct components.

- Connection Size- Safety Valves come in a wide range of connection sizes and types. The valve size needs to be as big as your inlet size and the discharge piping. You will also need to determine your type of connection (ie male vs. female).

- Required Capacity- Determining the maximum capacity is crucial to ensuring the safety of the valve. Pressure safety valves have their limits, so make sure to verify that your PSV can withhold the maximum capacity of your application.

What Causes over-pressurized vessel?

An overpressure event is defined as any condition that could cause the pressure of a vessel to exceed the maximum working pressure. There are several factors and scenarios that can result in over-pressure in a vessel including, but not limited to, blockage outlets, a cooling system failure, thermal expansions, external fires or heat, chemical reactions, or a valve malfunction.

The above events can all lead to overpressure, either individually or as simultaneous occurrences. Because there are so many variables that can play a factor in causing a potentially dangerous situation, carefully selecting a pressure safety pressure valve is extremely important.

Safety Valve vs Relief Valve

Pressure Safety Valves (PSV) are also commonly referred to as simply Safety Valves. They are used to relieve pressure from equipments operating Gases. Generally the valve opens suddenly, at an instant.

Pressure Relief Valves (PRV) are also commonly referred to as simply Relief Valves. They are a type of Safety Valve. They are used to relieve pressure from equipments operating Liquids. Generally the valve opens relatively gradually and proportionally.

The function of both PSV and PRV is that they relieve the excess pressure from the system by opening automatically and they get closed automatically when the pressure in the system normalizes.

As we know, there are numerous pressure relief valves available. In the market, we have a tendency to use terms like safety valve and relief valve interchangeably. And typically, this will make sense. Most pressure relief valves are made to perform the same factor – release pressure inside a system.

But what is the distinction between a few of these generally used terms, therefore, exactly what does it mean for you personally? Heres a fast introduction to two popular terms: safety valve versus. relief valve.

PSV vs PRV

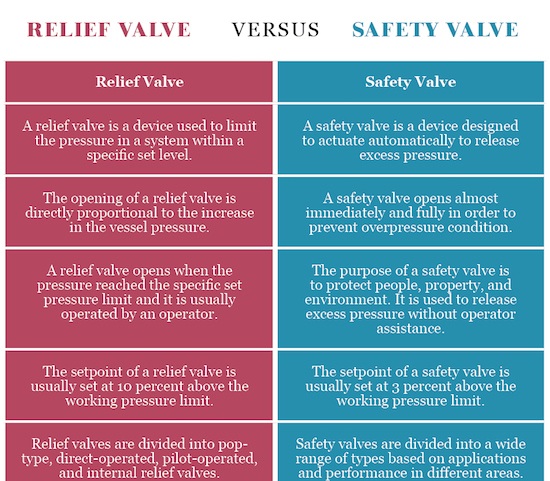

While both terms make reference to valves accustomed to release pressure from the pressurized system, their technical definitions really are a bit different. Generally, the word relief valve describes a valve inside a pressurized system which is used to manage pressure for that optimal functionality from the system. Relief valves are made to strengthen your facility avoid system failures, and safeguard equipment from overpressurized conditions.

The word safety valve, however, describes pressure valves that can safeguard people, property, and procedures. Quite simply, the word safety valve describes a failsafe, last measure valve which will release pressure to avoid a catastrophe, usually when other relief valves have unsuccessful to adequately control pressure inside a system.

Do Safety and Relief Valves Perform the Same Factor?

The overall reason for both safety valves and safety valve are identical. Both of them are pressure relief valves, and they’re made to let off pressure in almost any situation in which a system becomes overpressurized. That stated, relief valves and safety valves do function slightly differently:

- Relief Valves are made to control pressure inside a system, most frequently in fluid or compressed air systems. These valves open compared to the rise in system pressure. What this means is it normally won’t fly completely open once the product is slightly overpressure. Rather, they open progressively, allowing the machine to go back to the preset pressure level. When that much cla is arrived at, the valve shuts again.

- Safety Valves can be used for one good reason – safety. Rather of manipulating the pressure inside a system, they’re made to immediately release pressure in case of an urgent situation or system failure. Unlike relief valves, safety valves open immediately and completely to prevent a tragedy, instead of to manage pressure of the system.

While both safety valves and relief valves try to release excess pressure, how they do it is a touch different. Read this table, thanks to Distinction Between, for a bit more details about the variations backward and forward valves:

Can One Use Safety Valve and Relief Valve Interchangeably?

Now we have a much better knowledge of the technical definitions of both terms, you may be wondering if it is okay to carry on while using terms interchangeably. Generally, industry technicians will know very well what you’re speaking about whichever term you’re using.

If you are focusing on testing both kinds of valves, it’s vital that you comprehend the distinction between these valves, so you realize your facility is sticking towards the proper testing schedule. Otherwise, you shouldn’t need to worry an excessive amount of concerning the exact terminology. Both safety and relief valves are kinds of pressure relief valves, they’re just implemented a little differently.

Related Tags :

Ten articles before and after

Deal Between Rosneft and Vitol Fizzled Out – Zeco Valve | API approved valve manufacturer

IEA: EU Has High Dependence on Russian Gas – Zeco Valve | API approved valve manufacturer

LNG Market in China Has Overcapacity – Zeco Valve | API approved valve manufacturer

Slovakia Launched a Pipe to Supply Gas to Ukraine – Zeco Valve | API approved valve manufacturer

Nigerian President Appealed to Increasing Gas Supply – Zeco Valve | API approved valve manufacturer

What’s the difference between API and ASME standard ? – Zeco Valve | Industrial valve manufacturer

Russian Oil Export to Asia Reaching a New High Level – Zeco Valve | API approved valve manufacturer