The Japanese Industrial Standards Committee (JISC), Japan’s national standardization body, plays a central role in developing standards in Japan covering a wide range of products and technologies from robots to pictograms. JISC is also responsible for Japan’s growing contribution to setting international standards through its work with the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC).

“JIS” Stands for Japanese Industrial Standard and is published by the Japanese Standards Association (JSA) which is the equivalent of ANSI in the United States. They are created and updated by the Committee of the Japanese Industrial Standards (JISC). Like JSA to ANSI, the JISC is similar to the American Society of Mechanical Engineers (ASME).

1. Introduction of JIS Standard Flange

A flange is a general term used for items that connect pipes, valves, pumps, and other equipment to form a piping system. One of the best parts of using a flange is that they give very easy access for cleaning, inspection, or modification of the system. A JIS10K Flange is a slip on flange. This is different from other types of flanges, such as a welding neck flange or a lap joint flange. The JIS10K Flange is a slip on flange that follows the standard made by JIS, the Japanese Industrial Standard. Specifically, the JIS10K Flange that is used is made to the JIS B2220 standard. The word 10K comes from the fact that the JIS10K Flange has been made to fulfill the rigors of 10kg/cm² of pressure. This is all by the JIS B2220 standard created by the Japanese Industrial Standard.

2. Main Features of JIS Standard Flange

The JIS 10K Flange comes in multiple different sizes. This means that it is perfect for usage in many different situations, from small systems up to very large ones. The size range that is offered ranges from 3/8 inches up to 8 inches. The JIS10K Flanges were made up to code with the JIS B2220 design standards, and can work in pressures up to the standards set by JIS. These flanges are made in China. Furthermore, the materials used to make up the flanges are top notch which ensures the flange’s longevity and strength.

The steel that was used to make these flanges were SS400 steel and stainless steel, grade 316. The SS400 steel is a hot rolled steel composed of Carbon, Silicon, Sulphur (0.050 percent max), Phosphorus (0.050 percent max), Iron, and Manganese. Meanwhile, Stainless Steel SS316 is composed of Carbon (0.08 percent maxi), Phosphorus (0.045 percent max), Sulphur (0.030 percent max), Silicon (0.75 percent max), Chromium (16.00 percent max), Nitrogen (10.00 percent), Manganese (2.00 percent max), and Molybdenum (2.00 percent).

3. Applications of JIS Standard Flange

Flanges are mostly used for connecting pipes or to attach a pipe to another component. Blind flange is used in order to close the end of a pipe, so that the flow will stop at the point of blind flange installation. As installation only requires screwing two flanges together and the pipes that are connected using flanges can be disassembled easily as well. Most commonly found in plumbing or piping, flanges are used in things such as a sink in the house, in the piping system for showers and also for toilets as well. In the manufacturing industry, flanges are also commonly used in piping systems that have considerable amounts of pressure.

4. Slip On Flat Face Flange:

Slip-On flanges are the most popular pipe flanges used for pipe-to-borehole insertion. The slip on flange is a convenient option to weld on the neck. It can alter the length of the corresponding pipe. This space allows individuals working on the flange access to connect easily.

This flange design is more common in lower pressure assemblies and is less utilized when a high stress service requires a superior connection to the piping line assembly. This is because a slip on flange will accept a pipe with a fillet weld connection. On the other hand, a weld neck flange has a reinforced hub at the case that produces a weld beveled end connected directly to the butt weld pipe end connection. The tapered hub provides better service in mechanical stress environments. When compared to the cost of a standard flange, slip on flanges have a cheaper material cost.

5. Differences between a Flat Face and Raised Face Flanges:

The major difference between flat face and raised face flanges are the raised area that surrounds the pipe bore, whereas the flat face flange does not. A flat face flange cannot be connected with a raised face flange as it would result in leaking.

Flat Face Flanges

Flat face flanges have a surface area that is the same height thickness as the flange’s bolting line. The entire surface is flat, and a soft type complete face gasket is utilized to connect two flat face flanges. The gasket is usually composed of a non-metallic material like Viton or EPDM. The objective of adopting a flat face flange is to avoid the bending moment imposed on the flange when the bolts are torqued. Some flange materials are readily damaged while flat face flanges can solve this problem.

Blind Flanges

A blind flange is a circular plate with a bolt hole and a solid surface that is used to seal off a pipeline or to create the end flow. They are widely utilized in the petrochemical, public services, pipe engineering, and water works industries. The blind flange is placed between two open flanges to prevent liquid flow via a pipeline.

Blind flange is typically essential when undertaking pipeline maintenance or repairs as the flow in the pipeline must be stopped for maintenance, yet the nearest valve may be kilometers away from the repair site. As a result, installing a blind flange on a pipeline is far more cost-effective.

6. Installation of Flanges:

The general way to install flanges is to put a pipe through and close it with a pair of male and female flanges, with a gasket in the middle to prevent leakage and provide better sealing. This is called a flanged joint. There are a few disadvantages of using a flange, however. One of them is that it needs to be in a straight line, as well as a flanged pipe system needs more space than the pipe radius to work, which can limit the places where it is effective. These disadvantages, however, are heavily outweighed by the benefits. Flanges can be put into the system with advanced welding with piping, which easily saves costs and time. Putting a flange joint pipe together also means that the system itself is more flexible, and can easily be reconfigured or moved without the need to unwind a few parts. Considering the amount of pressure that the flanges must get through daily, the risk of leaking is apparent. This risk however is then minimized by the JIS10K Flange, as it has been made to follow the JIS B2220 regulations, and can easily withstand 10kg/cm² worth of pressure.

Japan Standard Flange Dimensions, JIS 2K/5K/10K/16K/20K/30K/40K/63K

BLIND FLANGE PLATE FLANGE SLIP-ON FLANGE

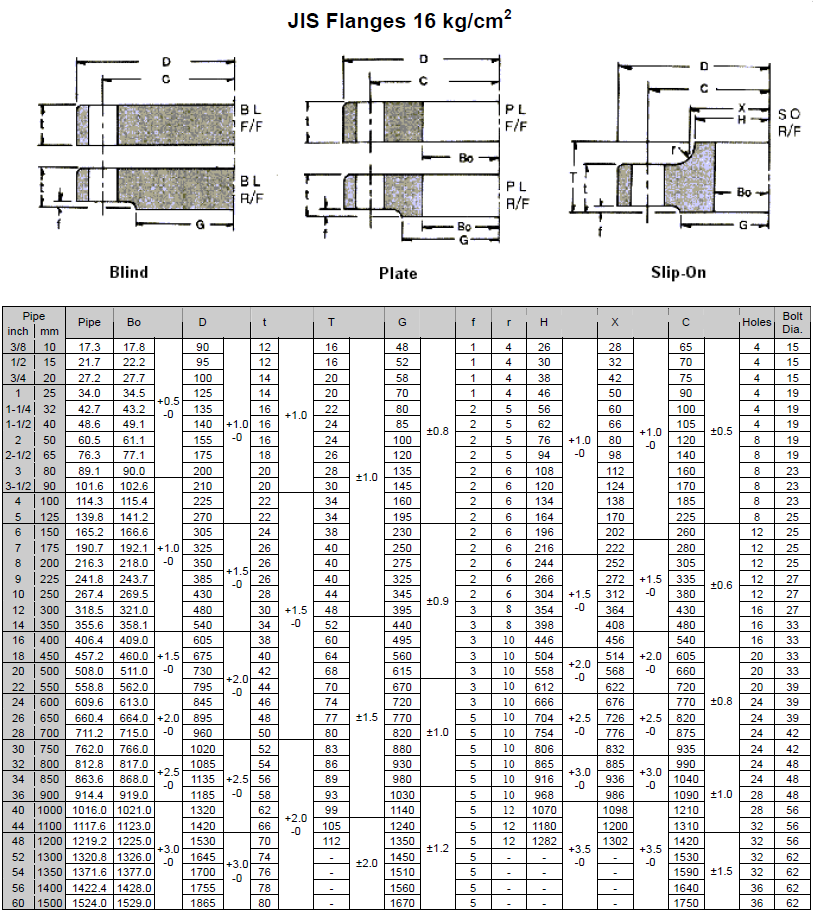

JIS Flanges 16K (kg/cm2) Dimension Chart

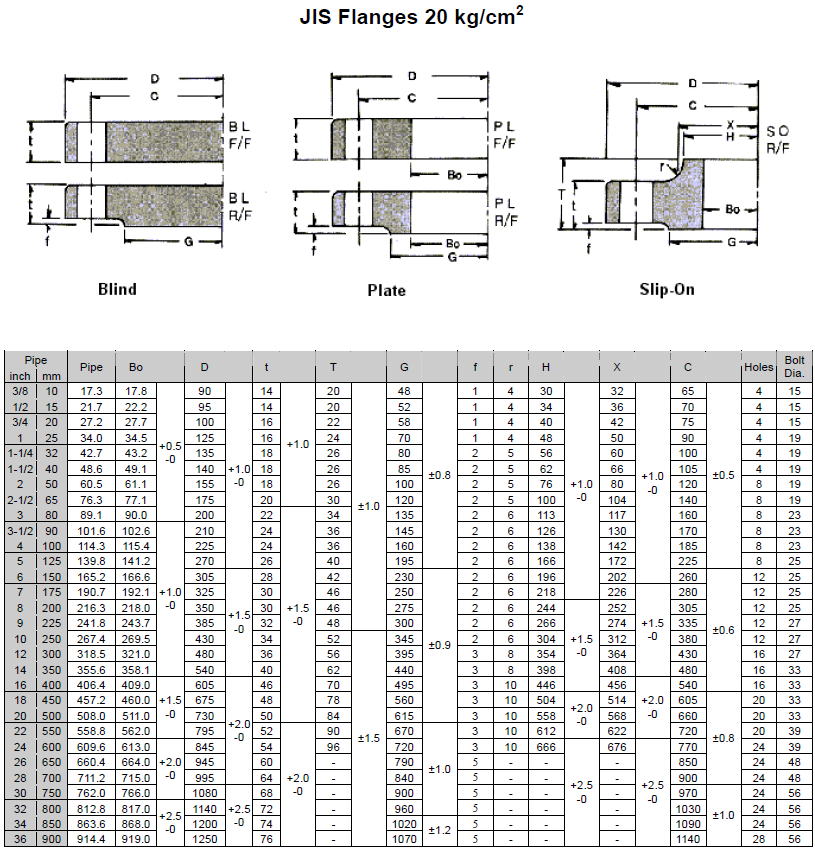

JIS Flanges 20K (kg/cm2) Dimension Chart

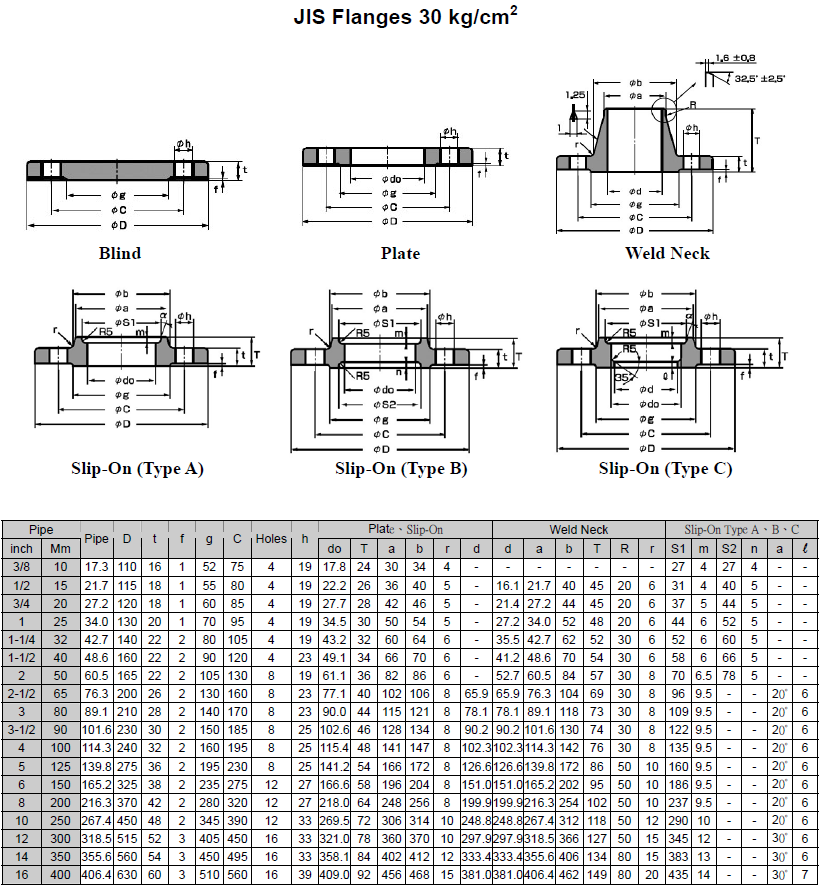

JIS Flanges 30K (kg/cm2) Dimension Chart

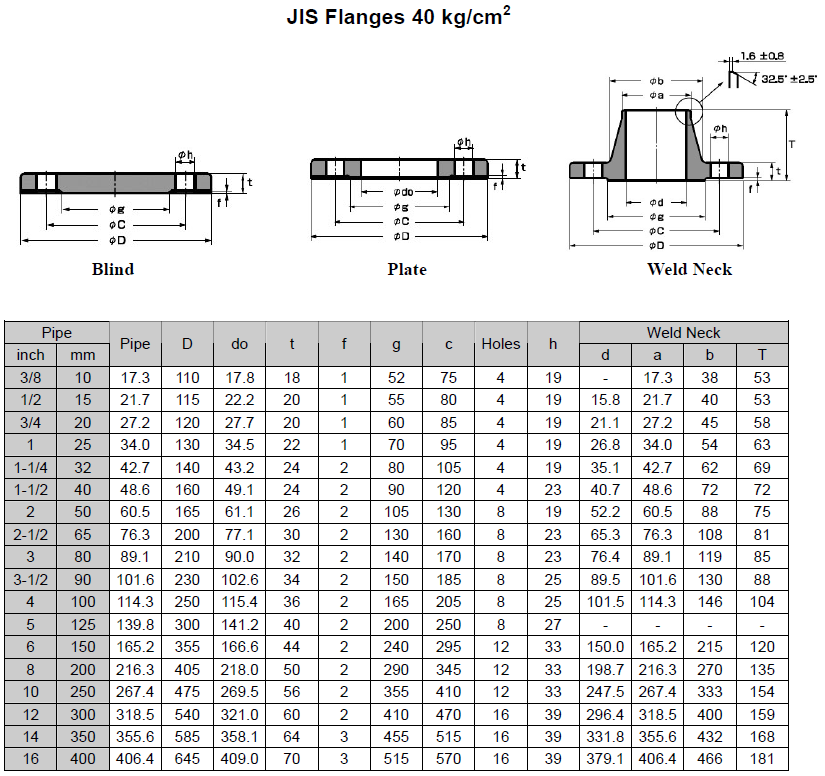

JIS Flanges 40K (kg/cm2) Dimension Chart

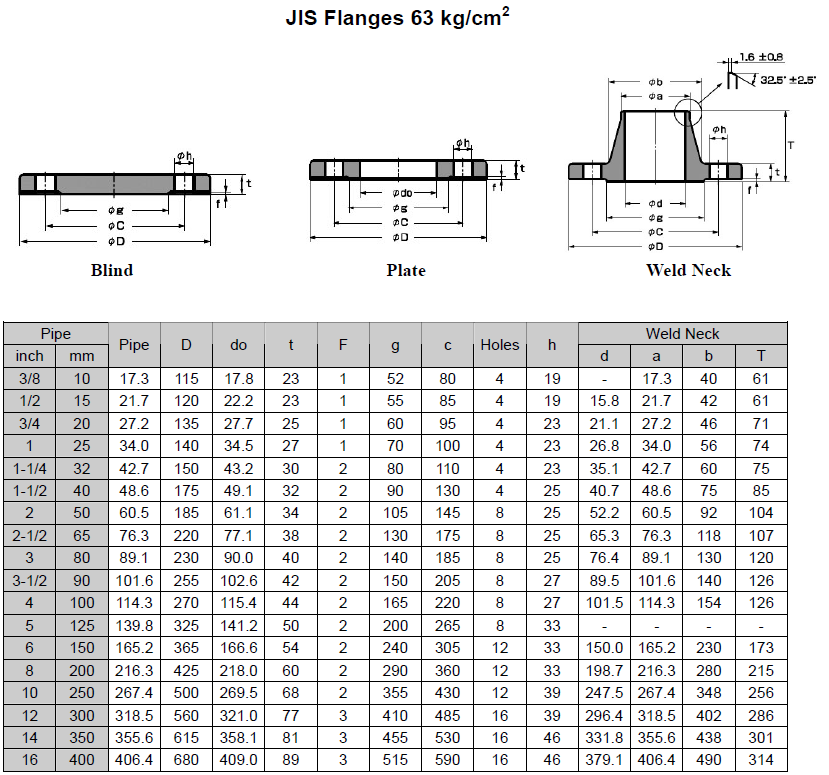

JIS Flanges 63K (kg/cm2) Dimension Chart

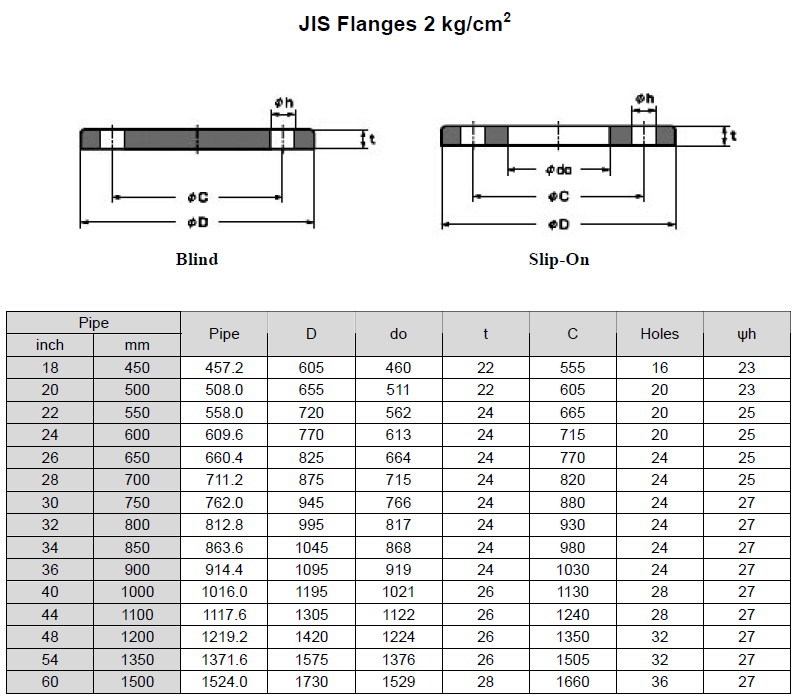

JIS Flanges 2K (kg/cm2) Dimension Chart

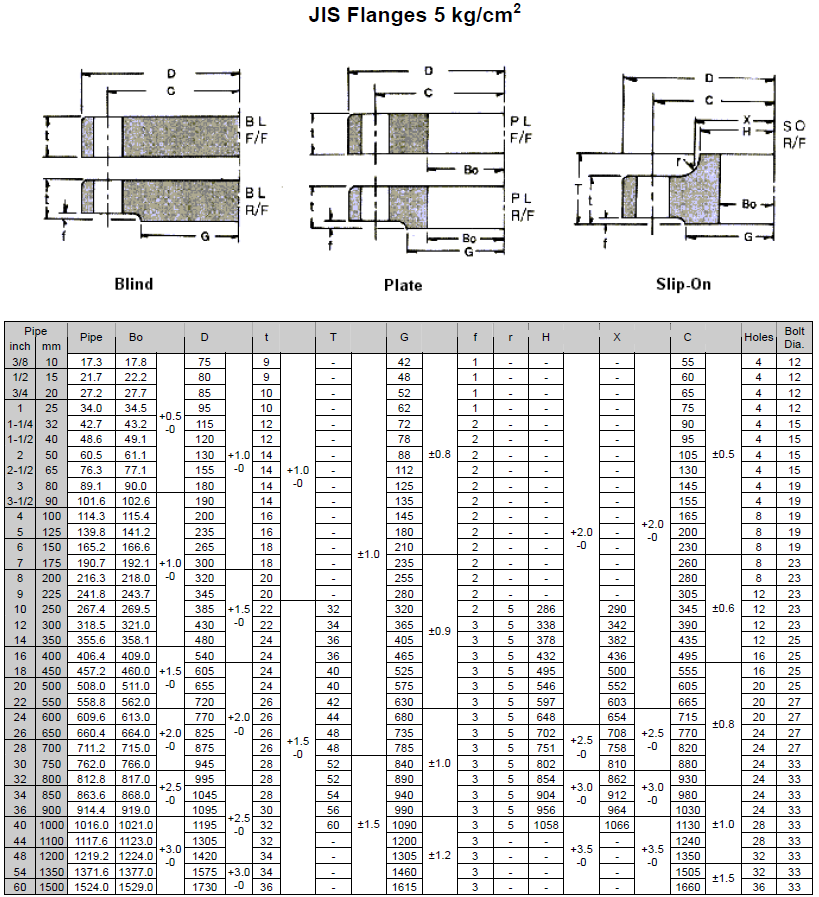

JIS Flanges 5K (kg/cm2) Dimension Chart

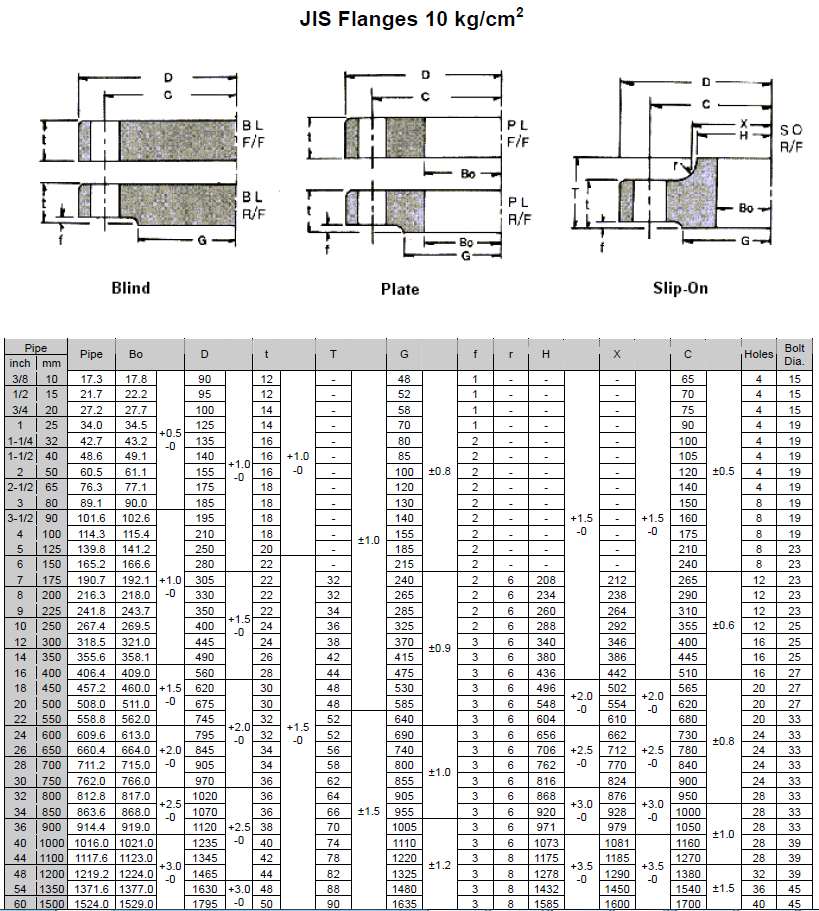

JIS Flanges 10K (kg/cm2) Dimension Chart

What are API standard flange?

Although the dimensions of ASME and API flanges may sometimes be compatible for bolting – using the same bolt circle and the same number of bolts – they do not share the same pressure rating system.

ASME rates the pressure of a class based on the material of construction and the design temperature

API specifies allowable materials and gives them a specific pressure rating

The difference between ASME/ANSI and API is the fabrication material and a higher rated API operating pressure.

ASME/ANSI flanges are commonly used in industrial process systems handling water, steam, air, and gas. API flanges are manufactured for high strength operating refinery systems with products such as oil and explosive gases.

Related Tags :

Ten articles before and after

Korea Imported Oil from The U.S. – Zeco Valve | API approved valve manufacturer

Chinese Economy Slowing Down Contains Gas Demand – Zeco Valve | API approved valve manufacturer

DIN(, JIS, ASME Standards Flange – Zeco Valve | Industrial valve manufacturer

Slovakia Launched a Pipe to Supply Gas to Ukraine – Zeco Valve | API approved valve manufacturer

LNG Market in China Has Overcapacity – Zeco Valve | API approved valve manufacturer

IEA: EU Has High Dependence on Russian Gas – Zeco Valve | API approved valve manufacturer

Deal Between Rosneft and Vitol Fizzled Out – Zeco Valve | API approved valve manufacturer