Slide gate valve is an equipment that fits into a system which are specifically designed for handling dry bulk powders, pellets, and granules etc.

What is a Slide Gate Valve?

Slide Gate valves are linear motion valves used for full bore fluid flow without any change in direction. They are designed to provide an efficient method for controlling the flow of free-flowing dry bulk materials. It is an ideal valve for transmission and interruption of fluid movement which is mainly suitable for crude, gas pipes, petrochemical oil depots, and other pipelines in the industrial process. The face of this type of valve is mostly parallel and hence they are often referred to as Parallel Slide Gate valves. They are generally either fully open or fully closed and are not normally used to regulate flow. However, slide gate valves can also be installed at the outlet of an oil pump to regulate and control the flow of liquid. A typical slide gate valve is shown in the figure below:

Design Principle of Sliding Gate Valves

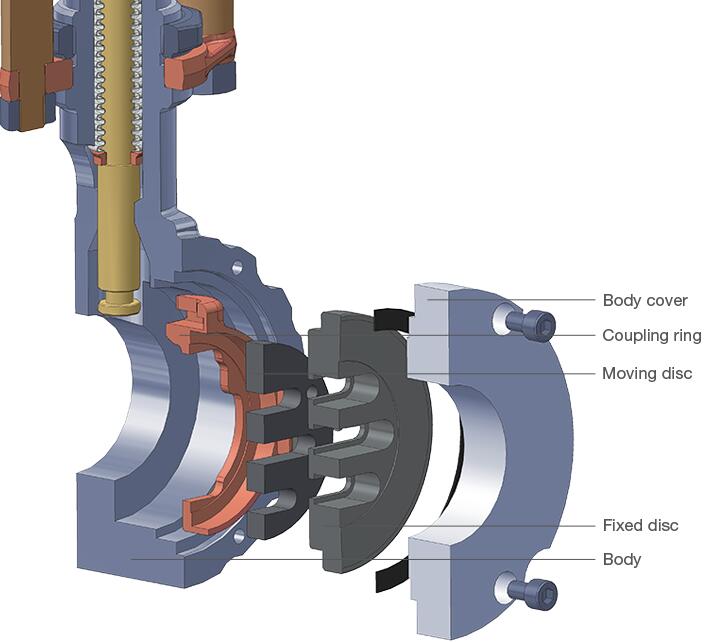

The sliding gate valves are characterised by a special throttle device in the functional unit that merely comprises two slotted disks that slide over each other and seal against each other. One sealing disc that is fitted in the housing perpendicular to the direction of flow has a predefined number of transverse slots. The second disc that is torque-proof and has the same arrangement of slots is moved perpendicular to the other one, this thereby changing the flow cross-section. The applied pressure differential presses the movable disc against the stationary disc.

How does a Slide Gate Valve work?

When there is no pressure or the pressure inside the valve (middle cavity, inlet, and outlet) is equivalent, the gate is closed, and the RPTFE sealing ring on the surface of the seat provides the initial sealing. The valve seat ring can automatically clean the sealing surface on both sides of the gate, each time it opens or closes.

The release of pressure from the cavity of the valve body forms an inlet seal and the medium pressure acting on the inlet valve seat moves it to the gate. This RPTFE seal & metal to metal sealing facilitates a soft and hard double sealing. Simultaneously, the O-ring ensures sealing between the outer circle of the valve seat and the valve body.

When the pressure in the cavity of the valve body is greater than the pressure of the pipeline, a pressure difference is created in the cavity. This pushes the inlet valve seat to the end surface of the upstream valve seat hole. The excess pressure inside the valve body in between the upstream seat and the sealing surface of the gate is released into the upstream pipeline which determines the automatic pressure relief function of the valve.

Applications of Slide Gate Valve

Silo discharge slide gate valves are generally actuated by pneumatic pistons. They are used for opening and closing product flow automatically to discharge the product to downstream equipment. Manually operated slidegate valves installed below silos or hoppers are generally used for maintenance operations of equipment like rotary valve, screw feeder etc that are installed below slide gate valve When installed on the gravity flow line, electrically actuated knife gate valves are used to adjust product flow speed. Slide gate valves can be installed at the inlet and outlet of dry bulk mixers. Feeding of powdered or granular materials are done before mixing. And mixed product is discharged after mixing.

Advantages of Slide Gate Valves:

- Sliding gate valves combined with with digital positioners provide excellent controllability and accuracy.

- Short opening & closing times, and maximum control performance, due to short stroke of sliding gate valve.

- High control with low leakage rates & long service life.

- Low actuation forces, compact design, low weight

- Long service life, minimal wear, low operating costs

- Precise control with high dynamics

- High cycle performance with very short cycle times

- High KVS values, easily exchangeable

- Low noise emission and no cavitation sensitivity

- High degree of tightness, low leakage due to the functional principle

- Simple design, easy to install and maintain

- Reduced energy consumption and low insulation losses

Related Tags :

Ten articles before and after

Gate Valve Vs Butterfly Valve Comprehensive Compare Guide

How to Measure Butterfly Valves

What is a Double Offset Butterfly Valve

How to Fix a Leaking Butterfly Valve?

Happy Holidays and Happy New Year from Zeco Valve | Zeco Valve Blog

Heat Exchangers for Liquid-Gas Vaporization | Zeco Valve Blog

High Performance Butterfly Valve Exploded View | Zeco Valve Blog

Improving Maintenance and Reliability of Bubbler Systems | Zeco Valve Blog

Cavitation in a Water Pump and Valve – Excellent Visual and Audible Demo… | Zeco Valve Blog