What are Slurry Valves?

Slurry valves are a type of valve designed for use with slurry, a mixture of solid particles and liquid. Slurry valves are used in various industries, including mining, oil and gas, and chemical processing. Slurry valves are different from other types of valves because they must be able to handle the abrasive and corrosive nature of slurry. Slurry valves are also designed to operate under high pressure and temperature conditions.

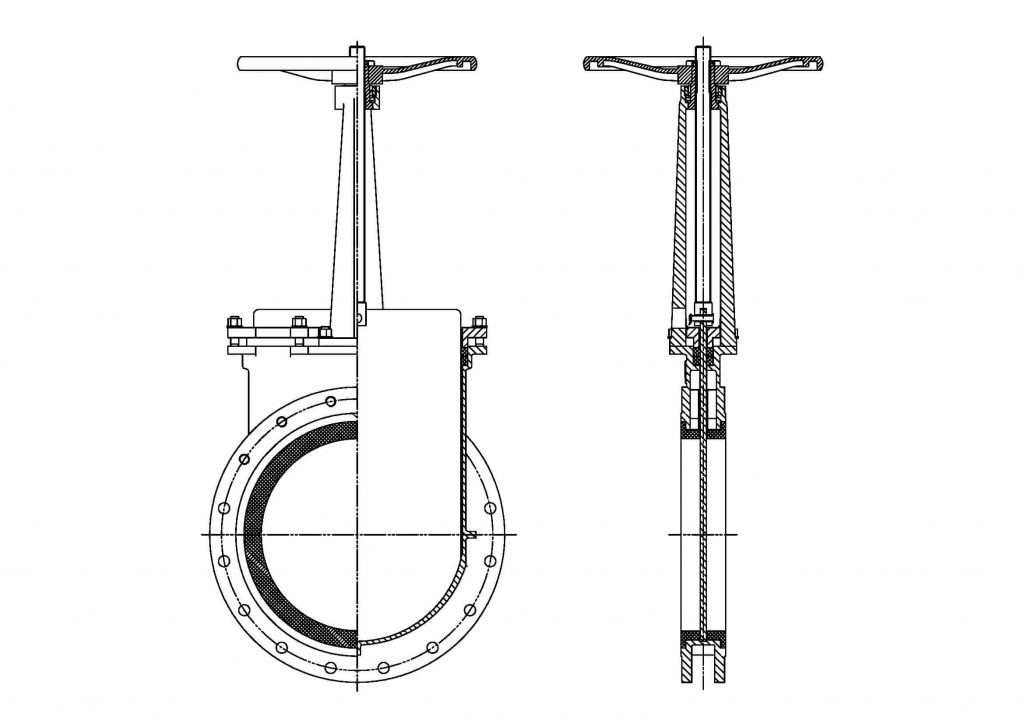

Ceramic Knife Gate Valve

Knife gate valves have simple structure and knife gates can cut off medium which contains solid particles and fibers, but for some very hard particles or serious erosive mediums, general metal seated knife gate valves will be washed out easily. As a professional and experienced ceramic valve manufacturer, ZECO Valve also developed ceramic knife gate valves to solve this problem.

Specifications of Ceramic Knife Gate Valve

| Type | Ceramic Knife Gate Valves |

| Size | DN50-DN400(2”-16”) |

| Pressure Rating | PN6, PN10,PN16, CL150 |

| Body Material | WCB, CF8, CF8M, CF3M,CN7M |

| Trim Material | Knife gate: SS201, SS304, SS316 + Nitriding, Hard Chrome, Tungsten Carbide, Stellite. Seats: Ceramics |

| End Connection | Lug Type, Wafer Type, EN1092-1, DIN 2501, ASME B16.5 |

Features of Ceramic Knife Gate Valve

- The valve is used in an excessive wear pipeline for isolation function. The valve is compact in design and easy to install. The ceramic seal face has good hardness (HRC ≥ 90 ) and is good at handling abrasion, solving the problem of hard and brittle ceramics, and effectively ensuring high wear resistance and corrosion resistance. The valve plate is made of high chromium alloy with high wear resistance, and impact -resistance and it can be used for throttling. Besides, the valve is featured with light and easy opening and little friction. The reasonable design eliminates the ash & slag build-up on the valve chamber.

- The valve can be installed horizontally or vertically, not inversely.

- Installation and tough-in dimension.

Slurry Ball Valve

Two of the most common types of valves you’ll find in slurry applications are ball valves and pinch valves. However, pinch valves have several limitations that may make them impractical for your application. For example, they may not do well in high-temperature or high-pressure applications. Therefore, a metal seated ball valve is often a better choice for severe service slurry applications.

Depending on the industry, slurry valves must resist many harsh conditions. They must withstand erosion from the solids in the slurry and often come in contact with corrosive liquids. Also, many applications require the valves to stand up to high temperatures and high pressures. Therefore, you need valves that are extra durable.

A metal seated ball valve offers the leak-tight seal you need while also resisting wear and tear for longer. This means reducing the risk of frequent failures and replacements and a longer lifecycle for your valve. Generally, you want to work with a valve specialist to customize the valve to your specific needs.

Related Tags :

Ten articles before and after

Repeat order of ceramic knife gate valves for fly ash | API 6D ball valve manufacturer