Advantages and Limitations of Ball Valves

The benefits of using a ball valve are the following:

- Ball valves induce a low-pressure drop compared to other types of valves since the flow has minimal restrictions. In liquids, a high-pressure drop across a valve may result in turbulence and cavitation. Cavitation happens when the liquid pressure falls below the critical pressure, and the vapor phase of the liquid is formed. As the pressure recovers, the bubbles collapse which damages the valve.

- Since it only requires a one-quarter turn to fully shut off or open, the ball valves immediately restrict or allow flow. This advantage is important for controlling the liquid level of a tank or a reservoir.

- A small amount of torque or a small actuator is needed to rotate the ball valve.

- Lubrication is unnecessary because of the surface properties of the seats.

- Ball valves offer a reduced chance of leakage because the ball seals tightly against the seats. The sealing action is done by fluid pressure.

- Several ball valve designs are available to satisfy a specific application. Some ball valve designs feature pressure relief, variable flow rate control, flow splitting, mixing, etc.

- Ball valves are relatively cheaper.

There are several limitations the user must remember to preserve the functionality of the ball valve:

- Throttling is possible in ball valves, but it should be sustained for a long time. When the ball valve is in a throttling position, the seats are exposed to the high-velocity fluid flow and more compressive force, which causes erosion. Therefore, it is not advisable for throttling applications. Standard ball valves may be used in throttling low-pressure gases. Segmented ball valves may be used in limited throttling applications. However, advanced ball valves with modified designs or seats made from engineered materials that are suitable for throttling applications are commercially available.

- Application is limited by the maximum allowable working temperature of the seats. For higher temperatures, metal or ceramic seats are an alternative.

- Suspended particles may build up between the body and the ball, causing leakage, erosion, and valve failure. Hence, it is advised to do frequent maintenance on ball valves handling slurries and suspensions.

Function of Ball Valves

The ball valve evolved from the plug valve. Its opening and closing parts are a ball. The ball is used to rotate 90 ° around the axis of the stem to open and close the valve. The ball valve is mainly used to cut off, distribute and change the direction of medium flow on the pipeline, and can also be used as a switch.

The ball valve with a V-shaped opening also has a good flow regulation function. Ball valve not only has a simple structure and good sealing performance but also has the characteristics of small volume, light weight, less material consumption, small installation size, small driving torque, simple operation, and easy-to-realize quick opening and closing within a certain nominal size range. It is one of the fastest-growing valve varieties in recent decades.

The use of ball valves is very extensive. The variety and quantity are still expanding, and to high temperature, high pressure, large diameter, high sealing, long life, excellent regulation performance, and one valve multi-functional direction. In China, the ball valve is widely used in petroleum refining, long-distance pipeline, the chemical industry, papermaking, the pharmaceutical industry, water conservancy, electric power, municipal administration, steel, and other industries, and plays an important role in the national economy.

Disadvantages of Ball Valve Function

As previously mentioned, ball valves are not ideal for throttling applications, as they do not allow for very fine control of flow. If you need to slow the flow of a fluid, a ball valve’s function is not a good choice — it should be used for opening or closing alone. They are also known to trap fluid in the bore when in the closed position, which can crack the valve if the liquid freezes.

One of the biggest problems with the ball valve function is that it is not multipurpose. Thicker liquids like slurries also pose problems for ball valves, sticking the valve in place so it cannot open or close, and generally causing wear and tear on the valve that will rapidly reduce its lifespan. Even using a ball valve in a high-velocity flow situation can cause problems, as the ball valve function is not designed to withstand this level of pressure and can cause a lot of erosion, fast.

Like most standard valves, a ball valve loses its function over time, wearing out through use. It is not a valve that will last forever by any means, so while it can be an affordable piece of equipment, it is likely something you will have to replace frequently.

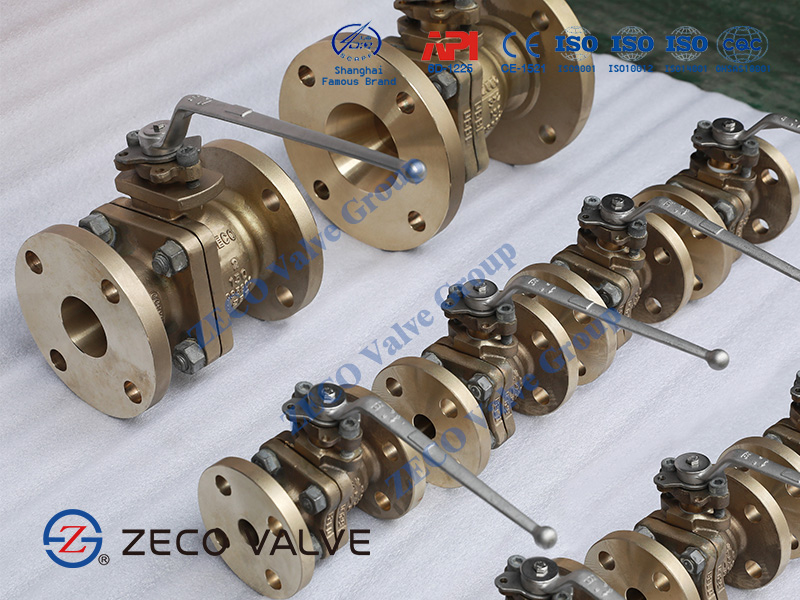

ZECO company has various types of ball valves for sale, such as floating ball valve, wcb ball valve, gear operated ball valve and so on. If you need more information, please contact us!