Pneumatic Ball Valve – Ball valve with Pneumatic Actuator

What is a Pneumatic Ball Valve? A pneumatic actuated ball valve uses compressed air to automate the control of media. Pneumatic actuated … Read more

GET RACK AND PINION VALVE ACTUATOR PRICE

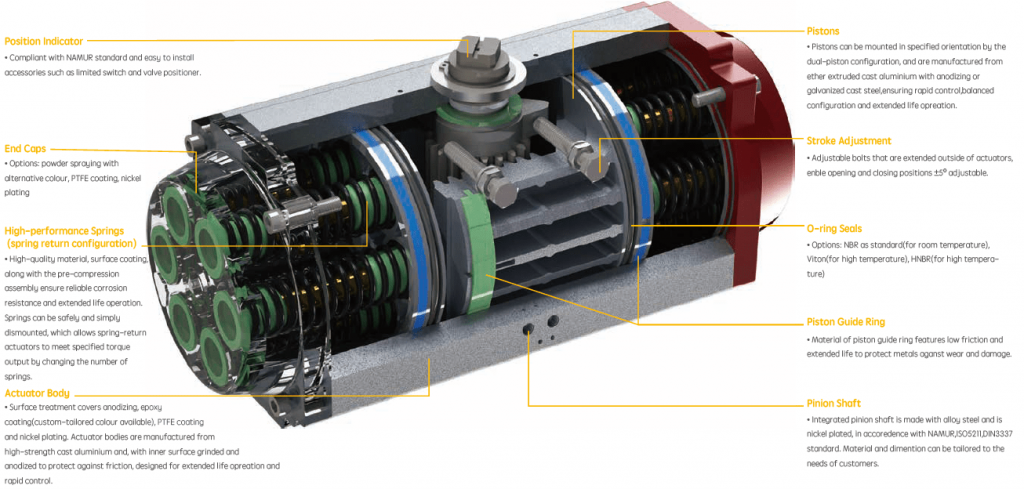

Rack and pinion actuators are mechanical devices used to automatically open and close valves or dampers, usually for industrial applications.

“Rack and pinion” is a generic term for a pair of gears that convert linear motion into rotational motion. A linear gear bar called “the rack” engages teeth on a circular gear called “the pinion”. The linear force exerted on the rack will cause a rotational motion of the pinion.

For valve automation, a common actuator design uses two piston-type racks moving in opposite directions to ensure balanced forces on the pinion. Typically, pneumatic air pressure is used to power the actuator. By applying pressure to the piston racks, the pinion can be turned to the desired position. The pinion bottom connects to the valve stem to open and close the valve as the pinion turns.

Pneumatic rack and pinion actuators offer many features and benefits for the operational actuation of the ball, butterfly, and plug valves.

Rack-and-pinion actuators offer the widest ranges of torque and rotation compared to other conversion mechanisms for converting linear force to rotational torque. It has high mechanical efficiency and the torques that they are able to produce range from a couple of Nm to multiple thousands of Nm.

However, one potential drawback of the rack-and-pinion design is backlash. Backlash occurs when rack and pinion gears are not completely aligned and there is a small gap between each geared connection. This misalignment can cause wear on the gears during the life cycle of the actuator, which in turn increases backlash.

A double rack unit uses a pair of racks on opposite sides of the pinion. This helps eliminate backlash due to a counter force and also doubles the output torque of the unit and increases the mechanical efficiency of the system.

In a single-acting actuator, the air is only supplied to one side of the piston and is responsible for the movement of the piston in only one direction. The movement of the piston in the opposite direction is performed by a mechanical spring. Single-acting actuators conserve compressed air but perform work in only one direction. A downside of single-acting cylinders is the inconsistent output force through a full stroke due to the opposing spring force.

In a double-acting actuator, the air is supplied to chambers on both sides of the piston(s). Higher air pressure on one side can drive the piston(s) to the other side. Double-acting actuators are used when work needs to be performed in both directions.

One of the advantages of double-acting cylinders is the constant output force through a full rotation range. The drawbacks of double-acting cylinders are their need for compressed air for movement in both directions and a lack of a defined position in case of a power or pressure failure.

| Problems | Inspection | Solutions |

| Pneumatic valve isn’t working | The solenoid valve or its coil is damaged./The solenoid ports are plugged. | Replace the solenoid valve or its coil. Remove contaminants attached to the solenoid ports. |

| Pneumatic valve isn’t working | Test with the actuator under air supply pressure, to check the piston seals for leaking and the actuator for damage. | Replace the worn down piston seals or damaged actuator. |

| Pneumatic valve isn’t working | The valve is plugged with contaminants. | Remove contaminants or replace the damaged parts. |

| Pneumatic valve isn’t working | The valve is switched to manual mode. |

Turn the handle of gear operator back to pneumatic mode. |

| Pneumatic valve is acting slowly, sluggishly | The motive pressure is incorrect. | Increase the air supply pressure to 0.4-0.7Mpa. |

| Pneumatic valve is acting slowly, sluggishly | The actuator is undersized with insufficient torque output. | Select the correct actuator model. |

| Pneumatic valve is acting slowly, sluggishly | There are problems with the valve binding or the other parts. | Re-adjust the valve binding. |

| Pneumatic valve is acting slowly, sluggishly | The power gas pressure is too low./The tubing connected to the gas is plugged. | Replace the accessories with larger ports./Remove blockage or filter |

| There is no indication from the limited switch. | There is a power board failure. | Check and repair the power supply. |

| There is no indication from the limited switch. | The position of the limited switch cam is not in accurate position. | Adjust the limited switch cam to the correct position. |

| There is no indication from the limited switch. | The microswitch has failed. | Replace the microswitch. |

What is a Pneumatic Ball Valve? A pneumatic actuated ball valve uses compressed air to automate the control of media. Pneumatic actuated … Read more

TOP 5 Pneumatic Rotary Actuator Manufacturers Festo is a company founded in 1925 and headquartered in Germany that provides actuation technology for … Read more

Valves are used to control pressure and flow in a pneumatic system, but they require the use of additional accessories to provide … Read more

Three primary kinds of valve actuators are commonly used: pneumatic, hydraulic, and electric. Pneumatic actuators can be further categorized as scotch yoke design, … Read more