What is a Ball Valve?

A ball valve is a shut off valve that controls the flow of a liquid or gas using a rotary ball having a bore. Ball valves are a type of quarter-turn valve along with plug valves and butterfly valves. They can be operated manually or by using an actuator.

How does a Ball Valve work?

The simplest operation of a ball valve is through the use of a wrench or a lever manually turned by an operator. Torque is applied to rotate the lever arm by 90° either clockwise or counterclockwise to open or close the valve. If the lever arm is parallel to the pipe, it indicates that the valve is open. If the lever arm is perpendicular to the pipe, it indicates that the valve is closed.

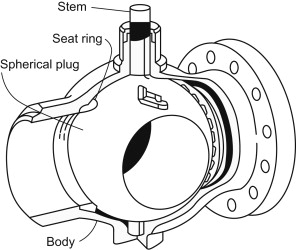

Parts of a Ball Valve

Ball

The ball is a sphere that has a hole in its center. The hole in its center is called the bore. The bore serves as the flow opening of the fluid when the cross-section of the fluid flow path and the bore is coplanar. Otherwise, the flow is throttled. A ball valve may have a solid ball or a hollow ball. A solid ball has a constant opening diameter throughout its structure, which helps the fluid to smoothly flow at a constant velocity. A hollow ball, on the other hand, has a hollow internal structure, and the space inside it allows more fluid to pass through the valve. However, the larger space creates turbulence and high velocities. A hollow ball is more lightweight and cheap compared to a solid ball.

Shaft

The shaft connects the ball to the control mechanism that rotates the ball. The shaft has seals such as O-rings and packing rings to seal the shaft and the bonnet to avoid leakage of the fluid. The shaft may be manually operated by a lever or a handwheel or operated by an electric, pneumatic, or hydraulic actuation.

Bonnet

The bonnet is an extension of the valve housing that contains and protects the shaft and its packing. It may be welded or bolted to the body. It is also made of hard metal and it covers the opening made from connecting the shaft to the external control mechanism.

Seat

The valve seats provide sealing between the ball and its body. The upstream seat is adjacent to the inlet side of the valve. The downstream seat is found on the opposite side of the upstream seat which is adjacent to the discharge side of the valve.

Causes of Ball Valve leaking at handle and internal

I. Causes of leaking ball valve

1. Causes of ball valve leaking internal during construction:

- Improper transportation and hoisting may cause overall damage to the ball valve, resulting in internal leakage of the valve;

- When leaving the factory, the ball valve was not dried and anti-corrosion treated after the completion of hydraulic pressure, resulting in corrosion of the sealing surface and internal leakage;

- The protection at the construction site is not in place, no blind plates are installed at both ends of the valve, rainwater, sand, and other impurities enter the valve seat, causing leakage;

- During installation, no lubricating grease was injected into the valve seat, causing impurities to enter the rear of the valve seat or internal leakage caused by burn during welding;

- If the ball valve is not installed in the fully open position, the ball will be damaged by the welding spatter. If the ball valve is not installed in the fully open position, the ball will be damaged by the welding spatter. When the ball with the welding spatter is opened and closed, the valve seat will be further damaged, resulting in internal leakage.

- The sealing surface is scratched by welding slag and other construction leftovers;

- If the ball valve stem drive sleeve or other accessories are misaligned with the assembly angle, the valve will leak.

2. Causes of ball valve leaking internal during operation:

- The most common reason is that the operation manager does not maintain the industrial ball valve in consideration of the relatively expensive maintenance cost, or the lack of scientific valve management and maintenance methods does not carry out preventive maintenance on the valve, resulting in equipment failure in advance;

- Internal leakage caused by improper operation or failure to maintainbyh maintenance procedures;

- During normal operation, the construction remains scratch the sealing surface, causing internal leakage;

- Improper pigging causes damage to sealing the surface and internal leakage;

- If the valve is not maintained or moved for a long time, the valve seat and ball will be locked, and the sealing damage will be caused when the valve is opened and closed to form internal leakage;

- If the valve switch is not in place, internal leakage will be caused. No matter whether the ball valve is opened or closed, the general inclination is 2 ° ~ 3 °, which may cause leakage;

- Many large caliber ball valves have stem stop blocks. If they are used for a long time, rust, dust, paint and other sundries will accumulate between the stem and stem stop blocks due to rust and other reasons, which will cause the valve unable to rotate in place and cause leakage. If the valve is buried, extending the stem will produce and drop more rust and impurities, which will prevent the ball from rotating in place. Cause valve leakage;

- The general actuator is also limited. If it is corroded for a long time, the grease will harden or the limit bolt will be loose, which will make the limit inaccurate and cause internal leakage;

- The valve position of the electric actuator is set forward, which is not closed in place, causing internal leakage;

Due to the lack of periodic maintenance, the sealing grease becomes dry and hard, and the dried sealing grease accumulates behind the elastic valve seat, hindering the movement of the valve seat, and resulting in seal failure.

II. Cause of ball valve leaking at handle

- First check the limit of the valve to see whether the internal leakage of the valve can be solved by adjusting the limit.

- Inject a certain amount of grease to see if it can stop the leakage. At this time, the injection speed must be slow. At the same time, observe the change of the pointer of the pressure gauge at the outlet of the grease gun to determine the internal leakage of the valve.

- If the leakage cannot be stopped, it may be caused by the hardness of the early injected sealing grease or the damage to the sealing surface. It is recommended to inject valve cleaning fluid at this time to clean the sealing surface and valve seat of the valve. Generally, it should be soaked for at least half an hour. If necessary, it can be soaked for several hours or even days, and the next treatment should be carried out after all solidified substances are dissolved. In this process, it is better to open and close the movable valve several times.

- Refill the lubricating grease, open and close the valve intermittently, discharge the impurities from the back cavity and seal the surface of the valve seat.

- Check in the fully closed position. If there is still leakage, inject the reinforced sealing grease, and open the valve chamber for venting at the same time, to generate a large pressure difference, which helps seal. In general, the internal leakage can be eliminated by injecting the reinforced sealing grease.

If there is still internal leakage, the valve shall be repaired or replaced.

How to fix a Leaking Ball Valve?

- Shut off the fluid flow to the leaking valve.

- Remove the handle from the stem.

- Loosen and remove the packing nut.

- Inspect the packing glad and internal components closely. Look for damage or signs of wear and tear. At this point, you must diagnose the valve and choose from the following solutions:

- Re-lock the packing gland evenly.

- Increase packing material.

- Replace old packing materials with new ones.

- Replace the valve entirely.