The anti-static device is another basic and mandatory design for ball valves.

What is Anti-Static Device for Ball Valve?

During the operation of the valve, the constant friction between the ball and the soft seat will generate static electricity. The spark caused by static electricity may ignite the inflammable fluid inside the valve and cause a potential fire hazard.

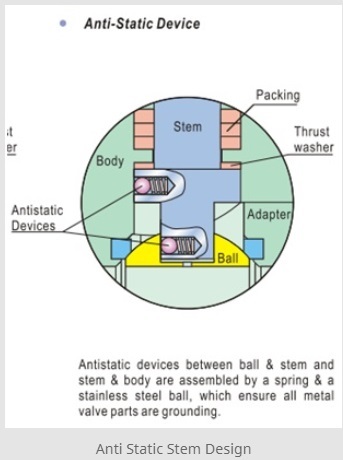

To get rid of the hidden danger, an anti-static device is invented for the ball valve. Like the picture shown below, the anti-static devices are located between the ball and stem & stem, and the body is composed of a spring and a stainless steel ball, which make sure that all the metal parts of the ball valve are grounded. In this way, the static charge could be transmitted

from ball to stem, and then from stem to body and ground, to prevent any potential fire hazard caused by static charge inside the valve.

That is how an anti-static device works. We hope this article could help you better understand ball valve design. You could check our blog for more valve knowledge.

Anti Static Design

People who have more technical information about valves know that in many cases, valves have anti-static requirements.

1. Generation of static electricity

Static electricity is a common physical phenomenon. When two different materials are rubbed, an electrostatic charge is generated due to the transfer of electrons. An object that receives electrons is negatively charged, and an object that loses electrons is positively charged. This process is called triboelectric charging. In theory, as long as the two objects of friction are compared, one side is more likely to lose electrons, while the other side is more likely to obtain electrons. Two objects of different materials can generate static electricity by friction. Friction between two objects of the same material will not produce static electricity.

2. Application of anti-static device in valves

In API 6D-2014, page 23, “5.23 Anti-Static Device” states: “Soft-seated ball valves, plug valves, and gate valves shall have anti-static devices.” API 6D-2014 only stipulates that a soft seat shall have an anti-static device, but does not require metal seat to have the anti-static device. This is because soft seat plastic seat (PTFE, PPL, NYLON, DEVON, PEEK, etc.) is prone to generate static electricity when rubbing with the ball (generally metal), but metal to metal seat, because the friction between the two groups of materials for the same, so there will be no static electricity.

3. Why should valves be designed with an antistatic device?

When the valve is soft seated, valve opening and closing parts will generate static electricity when the valve is switched, which is easy to generate sparks. If the medium is inflammable and explosive, the static spark is likely to cause the medium to burn or explode. The anti-static device discharges static electricity from opening and closing parts of the valve to the natural world, which avoids the static spark causing the medium to burn or explode, and protects the pipeline.

4. Application examples of anti-static devices in valves

Anti-static principle of the floating ball valve is as shown in the figure below:

The anti-static device consists of a spring and a steel ball (hereinafter referred to as the “electrostatic spring group”). Generally floating ball valve is composed of two sets of “electrostatic spring groups”, one of which is distributed on the contact surface of the stem and sphere, and the other is distributed on the contact surface between the stem and body, as shown in the figure above.

When the valve is in the process of switching, the ball and the seat are rubbed to generate static electricity. Because there is a gap between the stem and the ball when the stem drives the ball to rotate, a small ball in the “electrostatic spring group” at the place will jump, and static electricity on the ball is led to the stem. At the same time, the “electrostatic spring group” on the contact surface between the stem and the body, because of the same reason, static electricity on the stem is led to the body, the body is grounded, and finally, static electricity is completely discharged.

Why is the anti-static Design Essential for Ball Valves?

Static electricity is a common physical phenomenon. When two different materials friction, the transfer of electrons produces an electrostatic charge, this process is called friction electrification. In theory, two objects of different materials can produce static electricity when they rub together, but two objects of the same material cannot. When the phenomenon is produced in the valve body, that is, the friction between the ball and the non-metal seat ball, stem, and body will produce static charges when the valve is open and closed, which brings a potential fire hazard for the entire pipeline system. To avoid static sparkle, an antistatic device is designed on the valve to reduce or derive the static charge from the ball.

The antistatic device consists of a spring and a steel ball (” electrostatic – spring sets”). Generally speaking, floating ball valves consist of two “electrostatic spring sets”, one is on the contact surface of the stem and ball and the other is of the stem and body. When the valve is open or closed, static electricity is generated by friction between the ball and the seat. Because of the clearance between stem and ball, when the valve stem is driven by a sphere, the small ball of “electrostatic spring sets” bounce, which drives the electrostatic to the valve stem, at the same time, the valve stem and valve body contact surface of the electrostatic-spring sets, will export static to the body due to the same principle, will eventually electrostatic discharge completely.

In short, an anti-static device used in a ball valve is to reduce the static charge generated on the ball due to friction. It is used to protect the valve against a spark that may ignite the fuel flowing through the valve. The ball valve with an anti-static design is especially for a field like oil and gas, chemical, power plant, and other industries that fire-free is an important guarantee of safe production.

Related Tags :

Ten articles before and after

What Valves Can Be Used For Throttling? – Zeco Valve

What is the heat treatment of steel | Industrial Valve

What is the difference between 304,304H and 304L?

Fugitive Emissions and API Testing for Valves – Zeco Valve

Why Industrial Valves Fail and How to Repair – Zeco Valve

What affects the sealing performance III

The Blow-out Proof Stem of Ball Valve

Industrial Valves: Manufacturing Proces (How Valves are Made) – Zeco