Valves for Seawater Application

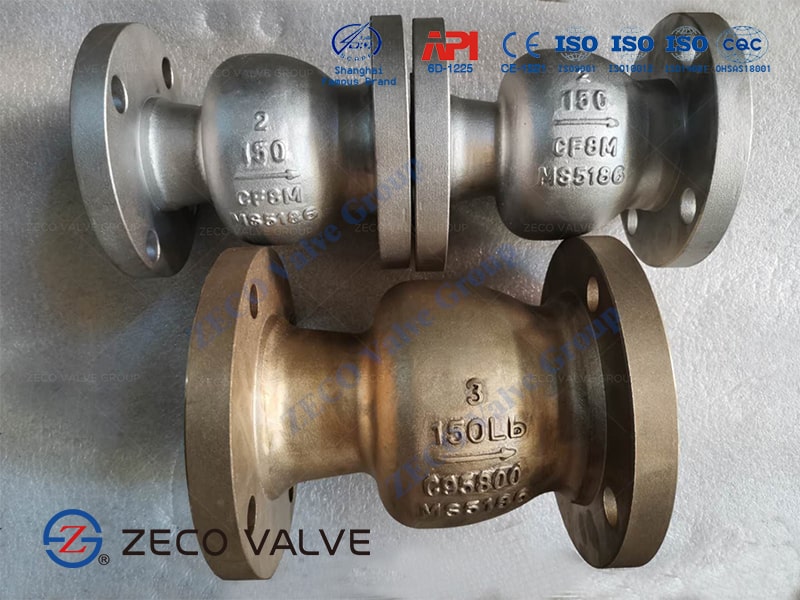

To solve the problem of seawater corrosion, we usually choose titanium, (Super) duplex steel, nickel aluminum bronze, or austenitic stainless steel to manufacture valves, which feature corrosion-resistance and washing-out resistance, ensure service life and longer replacement cycle, and help you save costs and improve the reliability of desalination.

Seawater Valve systems are used in a variety of industries including; desalination, oil & gas, coastal process plants, power stations, LNG loading and unloading facilities, and, of course, shipping.

In such industries seawater is primarily used for cooling systems. It is also used for fire fighting, desalination, and water injection in offshore oil production facilities.

Corrosion problems in seawater systems is well documented and have been subject to detailed studies over many years.

Corrosion in valves will be faster where cast iron or steel valves with nonferrous piping are used (2 to 3 years). Higher salinity, velocity, and to a lesser extent higher temperatures can accelerate the corrosion process.

Nickel aluminum bronzes have been established for many years as having an excellent reputation for corrosion resistance in seawater environments when comparing corrosion properties such as general corrosion, pitting, crevice corrosion, erosion-corrosion, cavitation, stress corrosion cracking, corrosion fatigue, and galvanic corrosion against austenitic and duplex stainless steels.

Selecting the Right Sea Water Valve

Seawater valves are often used as a fire protection fluid, both in offshore applications and for on-shore sites. Due to the high resistance of corrosion, seawater valves are preferred by the majority of people. So what factors should be taken into consideration in selecting the right seawater valve?

- Choose the right material for your seawater valve

- According to the valves for seawater application, different materials can be used variously in chlorine content. Right materials matter a lot for it lays the foundation of your seawater valve.

- Find the most effective solution for the seawater valve

- An analysis of the water composition is a promoter if you know the concentration of salts in the water.

- Ensure a professional seawater valve manufacturer

- Before selecting the seawater valve, pay more attention to the supplier and manufacturer. A professional and reliable producer can guarantee the quality of the valves and provide good after-sale service.

Seawater is an electrolyte solution containing various salts, which is a strongly corrosive medium to metal butterfly valves. Conventional metal materials can be corroded quickly by seawater and are not suitable as valves for seawater applications.

Methods to Prevent Sea Water Valve Corrosion

- Apply anti-corrosion coating to the valve surface. For example, the inside and outside of the valve are sprayed with an anti-seawater corrosion-resistant such as epoxy zinc-rich coating. This is the way with low cost, and its limitation is that one must be careful and make the coating will not be damaged before installing the valve to the pipeline.

- Use a corrosion-resistant material line for the butterfly valve component that contacts the media. For example, the valve body and the valve disc of the butterfly valve are lined with fluorine material such as PTFE, TEFLON, F4, etc. Also can be lined with rubber such as NBR, EPDM, Natural rubber, etc.

- The butterfly valve component has sufficient corrosion allowance. The wall thickness of the main contact medium such as the valve body of the butterfly valve increases, which can increase the using life.

- Use a suitable anti-corrosion material. Carbon steel like A216 WCB is not suitable for long-term seawater media. Gray cast iron and ductile iron have better seawater corrosion resistance performance and cost than ordinary austenitic stainless steel, which is a good choice.

- Copper metal is very good for seawater corrosion resistance. Common material grades are: B148 C95800, B148 C95500, Monel K400, Monel K500. Duplex stainless steel also has good seawater corrosion resistance and common material grades. There are: A890 4A, A890 5A, SS904L. Copper, and duplex stainless steel cost higher than iron material and have better performance.

Related Tags :

Ten articles before and after

Terms of Valve Structure and Parts – Zeco Valve | Quality valve supplier

Triple Offset Butterfly Valve With Bare Shaft – News – Zeco Valve | API Butterfly Valve supplier

Advantages and Disadvantages of O-rings – Zeco Valve | Quality valve supplier

ISO5211 Top Flange Dimensions – News – Zeco Valve | API Butterfly Valve supplier

Technical Terms of Valves – Zeco Valve | Quality valve supplier

Analyses of the Control Valves Noise – Zeco Valve | Quality valve supplier