The working principle of the ball valve is to make the valve unblocked or blocked by rotating the valve. The ball valve has the advantages of the light switch, small volume, large calibre, reliable sealing, simple structure and convenient maintenance. The sealing surface and spherical surface are often in the closed state and are not easy to be eroded by medium, so it is widely used in various industries.

Types of Ball Valve

Ball Valve Types Based on Structure

There are two types of ball valves, one is floating ball valve, and the other is trunnion ball valve.

Floating Ball Valve Characteristics include:

- No lower stem, providing savings during construction.

- Relatively small size range, typically from 1/2″ – 12″

- Tight sealing ability via the ball on the seat.

- Low operating torque.

- Downstream sealing only.

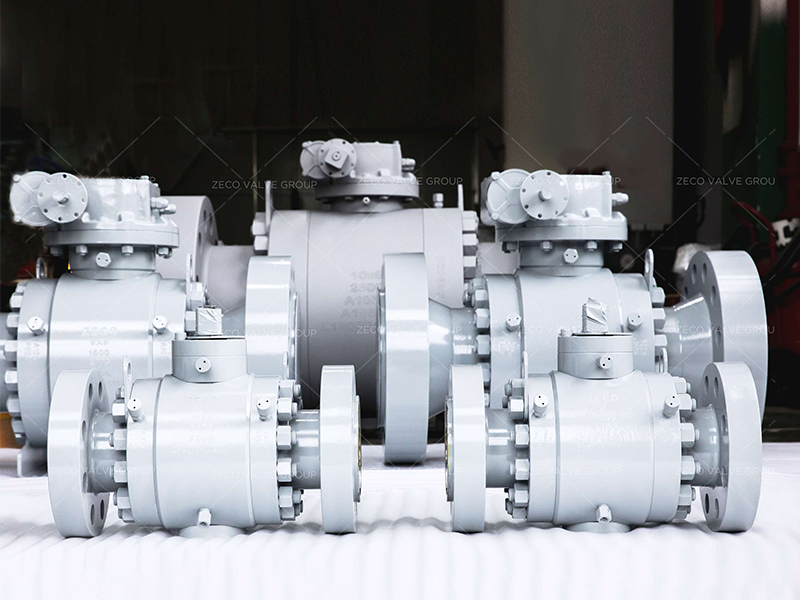

Trunnion Ball Valve Characteristics include:

- The ball is fixed, it does not float.

- The ball is centered by the stem at the top and the trunnion at the bottom.

- The seal is formed by the seats moving toward the ball.

- More complex than floating ball valves.

Ball Valve Types Based on Ball type

The ball valve has an O-type ball valve and V-type ball valve. The o-ball valve adopts floating structure, the ball core is precision casting, the outer surface is plated with hard chromium, the valve seat is made of reinforced polytetrafluoroethylene, the flow port is the same as the pipe diameter, and the flow capacity is great, the flow resistance is very small, and there is no leakage when it is closed, it is generally used as an on-off valve, especially suitable for high viscosity, fiber, and granular media; the v-ball valve adopts fixed structure, the ball core has V on it The flow characteristic is an approximately equal percentage.

Applications of Ball Valves

The ball valve is widely used in the irrigation system, mainly used at the inlet of the branch pipe. The ball valve is simple in structure, small in volume, and small in resistance to water flow. The disadvantage is that it can open or close too fast, resulting in water hammers in the pipeline (the pressure will rise when the water flow speed in the pipeline changes suddenly). Therefore, the ball valve should not be used on the main pipe. It can be used for flushing on the main pipe, branch pipe, or the end of the main pipe. The flushing and drainage effect is good.

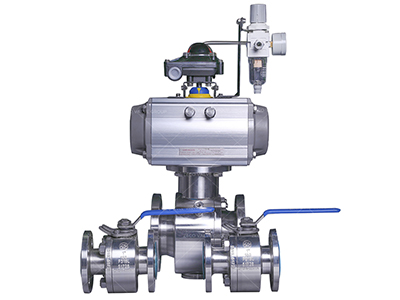

According to different process equipment, the pneumatic or electric actuator can be selected to form the pneumatic ball valve and electric ball valve respectively. If the pneumatic ball valve is to achieve proportional adjustment, it must be equipped with a valve positioner. If the electric ball valve is to achieve proportional adjustment, it must be equipped with an electronic actuator or servo amplifier.